2017 Audi A8 to feature more lightweight tech

The 2017 model's body shell will incorporate steel, aluminium, magnesium and carbon fibre together for the first time; hybrid powertrains are expected.

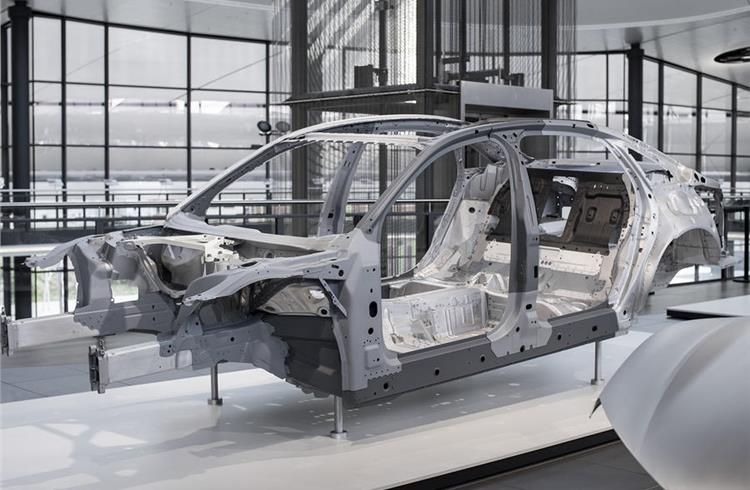

The new Audi A8, due later this year, will incorporate more lightweight technologies than ever before in its revised Audi Space Frame (ASF) architecture.

The body shell of Audi’s flagship will be a hybrid construction comprising four different materials for the first time. These are steel, aluminium, magnesium and carbon fibre joined using 14 different processes.

Despite Audi’s best efforts to reduce weight, the new body in white (the bodyshell less running gear and equipment) weighs 51kg more than the outgoing model, at 282kg compared to 231kg. Dynamic stiffness of the shell is up by 24 percent, which should contribute to improved handling, steering and refinement. Rear seat passengers get a 28mm increase in knee room and 14mm increase in headroom.

The weight gain is due to the need for more capable crash structures in the face of more stringent crash safety regulations. “The increase is also due to the need to accommodate new alternative powertrains and because of the increased specification our customers want,” said body engineer, Tim Hämmerle.

Another factor is the addition of protective measures relating to the hybrid powertrains. “Once you add a lithium battery to a car you have to think about how to protect it in the event of a crash,” said Dr Bernd Miekusch, chief body engineer.

The Audi A8 is expected to be equipped with a 48-volt electrical system and the body has been engineered for full hybrid systems, something which requires further protection from the body structure. “We have taken into account the possibility of a PHEV version of the A8 as well,” said a spokesman.” The extra weight is unlikely to be due to the new model growing in size. “It won’t be significantly larger” than the outgoing model, said the spokesman.

The rear bulkhead and parcel-shelf is made of carbon fibre using a new process developed by Audi and its suppliers weighing just 2.6kg. The bulkhead is made using carbon fibre tape laid up in different directions by machine, impregnated with resin and cured in just five minutes. The panel accounts for only one percent of the total body weight but accounts for 33 percent of the overall stiffness.

The aluminium components take the form of castings, extrusions and sheet. The body also incorporates high strength steel components and a magnesium cross-brace is used at the front of the car to further increase stiffness.

A number of new manufacturing techniques have slimmed down the B-Pillar and structures around the glass areas creating more comfortable entry and exit for rear seat passengers and improved vision. New techniques also include remote laser welding which is 53 percent faster than the previous laser welding process, uses 50 percent less heat and produces 25 percent less CO2.

RELATED ARTICLES

Antolin unveils sustainable tech solutions at Beijing Motor Show

In line with its China market roadmap, Antolin is showcasing its latest advances in lighting, HMI, electronics, and sust...

Visteon wins $1.4 billion in new business in Q1 2024, launches 26 new products

Digitisation of vehicle cockpit megatrend is a key growth driver for Visteon with over $400 million of displays wins; Vi...

BMW uses Catena-X ecosystem using real-world CO2 data to enhance quality

Working together with partners and suppliers, the company has modelled a complete data chain for the first time using re...

04 Apr 2017

04 Apr 2017

4876 Views

4876 Views

Autocar Pro News Desk

Autocar Pro News Desk