How 186,000 LED bulbs helped General Motors save Rs 490 crore

Sixteen GM facilities recently earned recognition for continued efforts to increase energy efficiency.

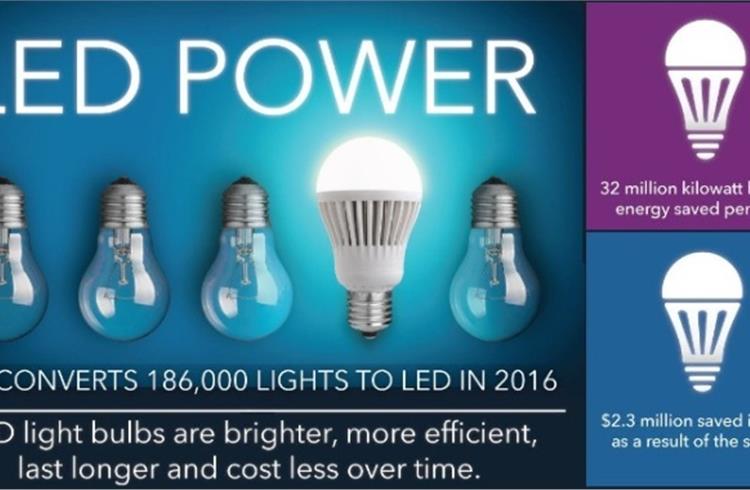

The installation of 186,000 LED bulbs is one of many steps that helped General Motors save US$ 73 million (Rs 490 crore) in energy costs in 2016.

Global efforts to increase energy efficiency play a significant part in GM’s goal of meeting the electricity needs of its worldwide operations with 100 percent renewable energy by 2050.

“Energy efficiency can reduce electricity loads, which will help us more easily transition to renewable energy sources. Together, these environmental improvements help us reduce our carbon footprint, cut costs and deliver value back to our customers,” said Al Hildreth, GM’s global energy manager.

Sixteen GM facilities recently earned recognition for continued efforts to increase energy efficiency.

GM’s Lansing Delta Township plant in Michigan and Fort Wayne assembly plant in Indiana earned Energy Star certification for superior energy performance. These plants are more energy efficient than 75 percent of similar buildings in the USA and meet strict performance levels set by the US Environmental Protection Agency.

Improvements included new doors that isolate airflow in paint shops at Lansing Delta Township and more efficient energy management systems at Fort Wayne Assembly. The Fort Wayne team also installed new variable-frequency drives that help cooling tower pump systems and fans operate with greater precision. Fort Wayne Assembly will receive nearly US$ 1 million in utility incentives over the next three years as a result. Both plants use LED lighting in new facilities.

GM warehouses in Waterford and Burton, Michigan also earned Energy Star certification. These customer care and aftersales operations leveraged natural light via new skylights, installed LEDs with motion sensors and are using energy management systems to control heating.

Another Energy Star program, the Challenge for Industry, recognises manufacturing facilities that have cut energy intensity by 10 percent within five years. This year, 12 GM sites met the challenge, 10 of which were repeat achievers and one in India. Moreover, on the occasion of Earth Day in March, GM India undertook several initiatives to spread the green message around the communities where its plants are located.

- Bedford Casting Operations in Indiana — first-time achiever

- Grand Rapids Operations in Michigan — first-time achiever

- Talegaon Engine plant in India

- Defiance Operations in Ohio

- Flint Metal Center in Michigan

- Hamtramck Assembly in Michigan

- Marion Stamping Plant in Indiana

- Qingdao Assembly in China

- Rochester Operations in New York

- Toledo Transmission in Ohio

- Tonawanda Engine in New York

- Wentzville Assembly in Missouri

“Improving the energy efficiency of our nation’s industrial facilities is critical to reducing greenhouse gas emissions and improving the health of businesses. From the plant floor to the boardroom, organizations are leading the way by making their facilities more efficient and achieving EPA’s ENERGY STAR® Challenge for Industry,” said Jean Lupinacci, chief of the Energy Star Commercial & Industrial Branch.

Grand Rapids Operations replaced 11,000 lights with LED tubes, improved its energy management systems and installed new variable-frequency drives on heating and cooling equipment. These activities resulted in an 18 percent reduction in energy intensity.

Bedford Casting Operations, an aluminum die casting facility, reduced its energy intensity by 12 percent through improvements such as installing high-efficiency burner controls on its melting furnaces and monitoring the energy use of facility equipment in real time.

You may like:

- General Motors aims for 100 percent renewable energy by 2050

- Shoe soles and rag washing helps drive GM’s global zero waste progress

RELATED ARTICLES

Antolin unveils sustainable tech solutions at Beijing Motor Show

In line with its China market roadmap, Antolin is showcasing its latest advances in lighting, HMI, electronics, and sust...

Visteon wins $1.4 billion in new business in Q1 2024, launches 26 new products

Digitisation of vehicle cockpit megatrend is a key growth driver for Visteon with over $400 million of displays wins; Vi...

BMW uses Catena-X ecosystem using real-world CO2 data to enhance quality

Working together with partners and suppliers, the company has modelled a complete data chain for the first time using re...

By Autocar Pro News Desk

By Autocar Pro News Desk

25 Oct 2016

25 Oct 2016

5458 Views

5458 Views