Dr Detlef Juerss: "Adient and Autoliv are jointly developing seats of the future."

Adient's vice-president (Engineering) and CTO and one of the top engineering minds in the global seating systems domain, speaks about the company’s partnership with Autoliv and the need for technology tie-ups to tap into the opportunities of the future, the impact of mega trends like autonomous driving, shared mobility and lightweighting, and the relevance of the Pune-based R&D centre in Adient’s global scheme of things.

Adient's vice-president (Engineering) and CTO and one of the top engineering minds in the global seating systems domain, speaks about the company’s partnership with Autoliv and the need for technology tie-ups to tap into the opportunities of the future, the impact of mega trends like autonomous driving, shared mobility and lightweighting, and the relevance of the Pune-based R&D centre in Adient’s global scheme of things.

Can you throw some light on Adient’s partnership with Autoliv to work together on futuristic technologies? I understand that India, as a market, is also a part of that.

Let me answer by framing a general statement. We are preparing for what we call CASE – Connected, Autonomous, Shared and Electric. To be ready for CASE, today no single OEM and no single supplier can have all the answers for all the questions.

What this means is you need collaboration partners, and this is a general industry trend. We see that OEMs are partnering each other. We see that new partners such as Google, Microsoft, and engineers developing artificial intelligence are all coming in.

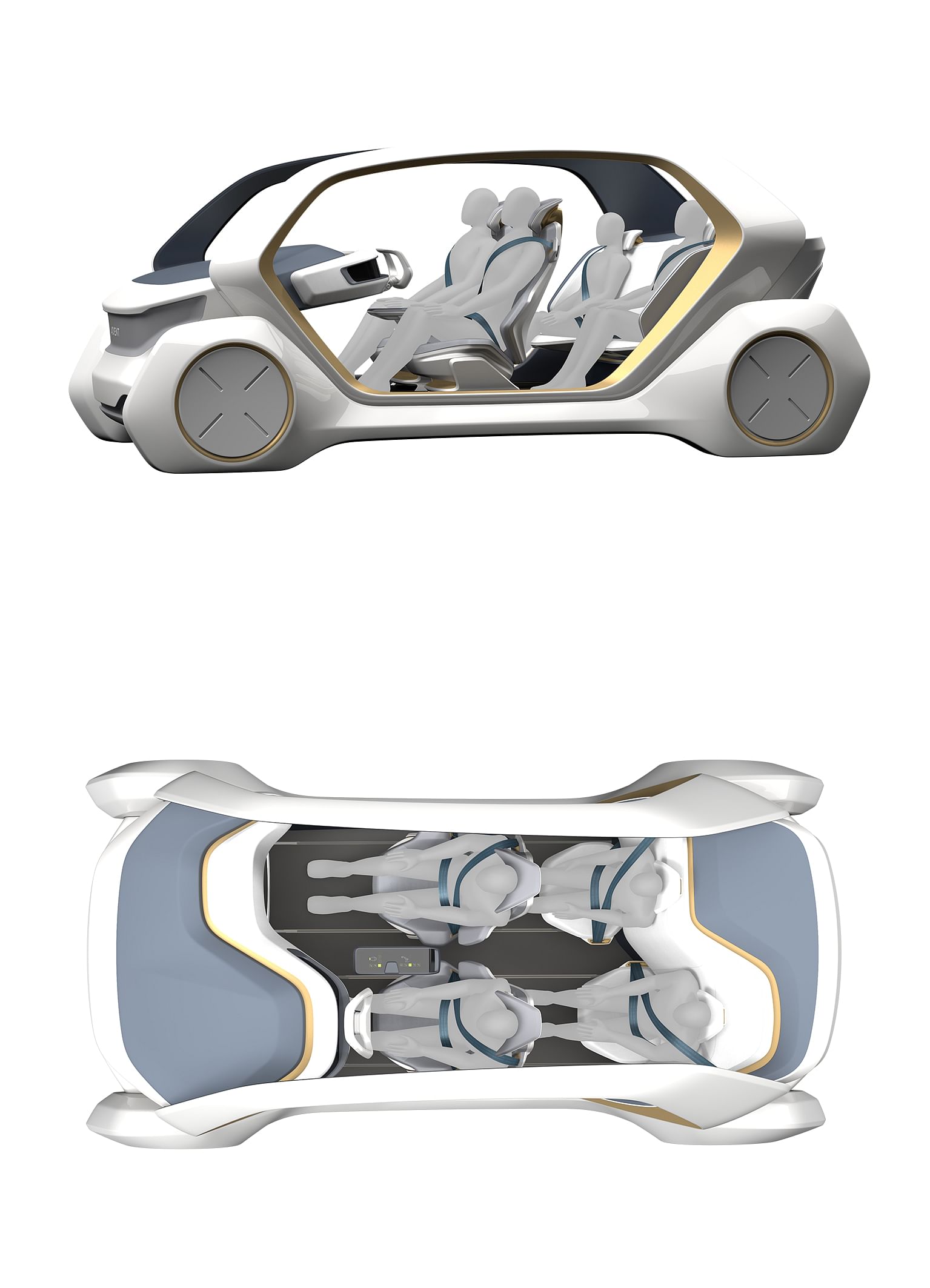

We, as Adient, being the biggest supplier of seating systems to the automotive industry, are very much interested in keeping people safe, comfortable and convenient in all those modes of transportation in the future. In order to keep them safe, we are seeing different uses of seats, starting from sleeping, relaxing or reading and other applications.

Different types of accidents happen and we, as the biggest seating supplier, are now even having due care requirement to provide the technology to the market that keeps people safe. To serve this purpose, we have chosen Autoliv because it has exactly the same mission statement – to keep people safe in cars.

Therefore, we are collaborating on advanced development project(s). Why I am specifically saying advanced development projects is because today’s normal projects under safety systems providers are directed by OEMs as the total vehicle safety architecture. So, having concepts on how to integrate new safety components and seats to keep people safe in all positions in case of real-life accidents is what our collaboration with Autoliv looks at.

We are going to present the first results of these advanced engineering project(s) sometime in the future. It’s no joint venture, there are no shares bought over, we are just developing seats of the future together.

This is a global activity wherein we are hosting meetings with Autoliv all over the world. For example, sometimes we are in Europe in Autoliv’s facility, sometimes in Plymouth (USA), or in Shanghai. Work on thoughts (from meetings with Autoliv) on the engineering and simulation are being held at our Pune-based R&D unit facility.

Beyond Autoliv, is Adient open to more technical partnerships while preparing itself for opportunities under the CASE purview?

It’s not only about being open for collaborations, it’s a necessity. We are in very close talks and are finalising a very similar (technical) partnership agreement with a company. They are one of the leading experts in HMI (human machine interface) and electronics. We are in talking terms with one of the leading suppliers of the whole vehicle body controller network architecture. We are talking to a company that will be a leading provider of heating and cooling elements inside the car because these are all the components that are potentially seen in the CASE scenario.

We are not necessarily saying that we will have fully-loaded, aircraft-like seats in every car. But, definitely, we need to be ready so that if there is a market for this, we can provide the solutions.

It must be very fascinating to pen down the new applications or features that passengers would like to use when they are commuting in an autonomous car. Is it

so for R&D too?

You would still need somebody to own that system and we would, hopefully, like to be that company at least when it comes to the seating systems. Somebody needs to orchestrate that. There can be so many new topics ranging from massage and relaxing applications, other services that are thinkable when people don’t have to concentrate on driving.

These are all cool opportunities for engineers but there also are challenges. For example, motion sickness and other problems in a moving car when you are not looking out on the street anymore. There can be safety topics encompassing passengers’ various sleeping positions.

Thus, there are significant technical challenges together with all these fantastic opportunities. That’s the reason why we are investing in increased engineering capabilities and capacity. This is also the reason why we are investing in India because this centre is truly a global hub for us.

How important is Adient’s Pune-based R&D centre in its global scheme of things?

As of today, this centre is doing 95 percent of our whole simulation (work) worldwide. All the FEA (finite element analysis) simulation technically is being done exactly here. A quarter of all global development projects, CAD and CAE is already being done here. It is our major and biggest contributor to every single global program.

It is the only technical centre that today is managing projects from Asia, Europe and North America. This is the only place where you can physically walk through and see projects from all regions. This (centre) for us is a true multiplier and melting pot of know-how and knowledge or knowledge databases.

We are now adding a little cherry on the cake with the prototyping and testing facility. With this facility, first of all, we will be able to create additional capacity just to do more development work here and also increase the skill sets of our engineers working here.

If an engineer really has the opportunity, and specifically simulation engineers, to physically go down there and watch the tests that he/she previously simulated, it will result in so much faster correlation improvement for the simulation. That will drive efficiency on the simulation front. It will drive skills and efficiency in the engineering team so that we will be able to do much more development work out of this tech centre, even though we might not increase the headcount significantly. We already have more than 850 engineers working here and another 150 working out of other location(s). We believe that with 1,000 employees we are pretty much maxed out. If you go in for more than that, you face organisational challenges.

Within automotive seating systems, how different can they get across different geographies?

We are not anymore differentiating between seating systems for different regions and markets so much. But it is absolutely true that today, specifically for the region of India, and I’ll be very precise, the region of Indonesia, the seats are still developed to relatively low specifications in terms of safety and comfort. This is so because honestly, these markets are still focusing on absolute costs than the latest safety standards or the latest comfort features.

Is this because in these regions the legislations are not at par with the global regulations?

No, this has nothing to do with the regulations. This has just to do with the market(s). By the way, the legal specifications around the world are (largely) the same, and they are super low (comparatively in terms of ideal standards).

For example, the recommendations from Euro NCAP are not legal specifications. These (ideal) specifications are, at the end of the day, consumer specifications. We believe that specifically in the region of India, consumers will demand higher specifications in their respective cars and that will then drive designs for seating systems, which are closer to what we are seeing in Europe, America, and in China.

The China market in the last five years has totally gone away from low-spec seating systems. The market leaders in China now have exactly the same specifications (for seating systems) as seen in the VW Golf sold in Germany or a GM being sold in the USA, which are of course ultra-high (in terms of specs).

Also, China has higher specifications when it comes to foam emissions. There we are currently using more expensive chemicals in order to meet those emission specifications.

Vehicle crash test agencies have created a lot of consumer awareness about safety and safety ratings of different passenger cars worldwide. As you said, consumer awareness and demands are going to drive the design and development of seating systems in future. How is this impacting your innovation and R&D at present?

Good question. This is exactly what I am talking about. At the moment, the consumers are demanding higher comfort and value on the inside of the car, which we are seeing in all segments. There is demand for seats with more comfort features (such as height adjuster, power seats, comfortable headrests and others). So we are seeing a trend of higher value seats even in small cars.

You can now order a Nissan Micra with seats offering comfort features such as a massage system with four-way lumbar support. We are seeing that the content is increasing all over the world.

Here in India, it comes from a very low level. But the markets are still so different. If you think about the highest selling car in the USA, it’s still the Ford F-150 versus the bestselling car in Europe, which is the Volkswagen Golf to the top-selling ones in China, the specs define the differences between these markets.

What kind of lightweight materials are put to work in order to develop lightweight seating systems? How do you drive innovation in terms of selecting the right materials to cut down the weight across frame, foam, fabrics or other components?

I have to say that we are spending about 30-40 percent of our advanced engineering budget on lightweight solutions, which include topics such as thinner foams, lighter foams, ultra-high-strength steel, new composites, magnesium and gluing technologies to have magnesium combined with ultra high-strength steel and others. Just the latest generation of recliners

and mechanisms are 25 percent lighter in weight than the previous generation. All these are huge investments.

We must understand why is all of this important. It is because when we are seeing more content coming into seating systems, we still don’t want to have the overall weight explode as every kilogram driven around costs energy, regardless of the fact if it is coming from a combustion engine or an electric engine. Energy, at the end of the day, is what we don’t want to waste. Therefore, lightweighting, with all those other fancy things,

is one of the top priorities for all OEMs.

You said 30-40 percent of your advanced engineering budget is allocated to lightweighting solutions. What percentage of total turnover is allocated to the R&D annually at Adient?

Smart question. I am sorry I cannot share all that information with you. All I can say is that it is a very significant amount. Just do the math, we have about 5,300 engineers around the world doing development work, and half of the engineering costs are people cost (including those involved in prototyping and testing).

Although autonomous cars are still some time away from mass adoption, shared mobility has picked up very fast. India too sees shared taxis being widely used by people to commute daily. What is the immediate impact of shared mobility on seating systems inside the car? Does this trend call for new requirements to existing car seats?

Absolutely. If you just think about the shared cars that are being driven around, these are the same Toyota, Suzuki and Mercedes cars just like other cars. But, as of today, we are already seeing different specifications for wear and tear and serviceability for cars that are being used as taxis and Ubers.

Moving forward, when we really see cars that are going to be physically made for specifically taxi operations. For example, the London Taxi is the only car that is particularly made for ferrying passengers.

The scenario will look totally different.

The seating systems in these taxis will look totally different in terms of space and convenience for the passengers, and will be absolutely different in terms of design for serviceability. So we see totally different requirements coming from the taxi segment, commuter trains, buses and public transport within the shared mobility space.

We are already learning a lot from the exercise that we are doing for aircraft seating because almost 99 percent of the requirements are requirements that go around durability, wear-and-tear, serviceability and other areas.

Are there any key takeaways from developing aircraft seating systems that are being implemented into

the advancement of automotive seats?

Absolutely. These are durability requirements on the surface materials. We are learning from the specifications of the durability requirements about how often the seat is being moved. Its order of magnitude is different than the ones in a normal passenger car.

(This article was first published in the December 15, 2017 Anniversary issue of Autocar Professional)

RELATED ARTICLES

'India Can Become a Major Pillar for Us' - Marquardt Group

Björn Twiehaus, CEO of Marquardt Group, and Vishal Narvekar, the company's India GM, share their outlook on the Indian m...

Luxury Car Market to Slow in 2025: Mercedes-Benz Sees Flattish Numbers

In Jan to March of 2025, the market may witness its slowest growth since COVID-19, and if the weakness continues, the se...

‘We Must Have More Women Leaders in the Auto Sector:’ Anjali Rattan

The chairperson of the New Delhi-headquartered RattanIndia Enterprises believes that with their multi-tasking nature, wo...

22 Feb 2018

22 Feb 2018

19319 Views

19319 Views

Darshan Nakhwa

Darshan Nakhwa

Prerna Lidhoo

Prerna Lidhoo