Xtrac showcases new powertrain solutions

Its major highlight at the Autosport International Show was the world's first commercially viable diesel-electric powertrain for a small family car.

The company also showcased new transmission developments including its brand new 529 gearbox for sports car racing, 516 gearbox for touring cars and the transmission system developed for the JCB DIESELMAX land speed record. The Zytek Xtrac hybrid showpiece fully meets the requirements of the Ultra Low Carbon Car Challenge. This £10 million UK government initiative is aimed at producing an energy-efficient small family car with exceptionally low CO2 emissions of under 100g/km, equivalent to a fuel consumption of at least 3.8lt/100km.

Zytek’s novel solution is a dual-mode system which combines the high efficiency of series hybrids at low vehicle speeds with the high efficiency of parallel hybrids at high vehicle speeds. It eliminates the compromises of other dual-mode hybrids by using sophisticated control strategies to replace clutches and complex epicyclic gear sets. The gearbox design and electronic controls allow the diesel engine and electric motors to be fully optimized for their function within the drivetrain.

“This new and innovative hybrid driveline really does drive home the technological capabilities of the motor sport industry and its ability to deliver energy-efficient solutions to the mainstream automotive sector,” commented Peter Digby, managing director, Xtrac.

To Xtrac’s credit, it earlier developed the transmission system for the 350mph record breaking performance of the JCB DIESELMAX project, which smashed the diesel land speed record at Bonneville last August. Xtrac supplied both gearboxes and differentials specified for the vehicle, which features two complete powertrain systems, one driving the front wheels and another driving the rear wheels.

529 SERIES GEARBOX

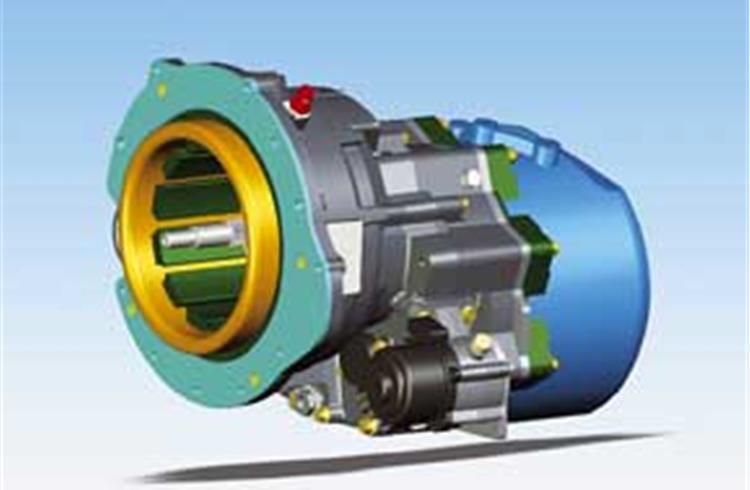

The transmission technology specialist also displayed its new 529 series gearbox, which is suitable for LMP1, LMP2 and GT1 class vehicles, and recently entered production at the company’s UK facility at Thatcham in Berkshire in readiness for the 2007 race season.

“Our new gearbox for endurance sports car racing is based on our Le Mans winning 229 transverse design, which has been one of the most reliable and successful gearboxes to be produced by Xtrac,” said Cliff Hawkins, development director.

##### The 529 gearbox is 3.4kg lighter than its predecessor and its development has led to a narrower lightweight cluster, a revised gear-change rack & pneumatic actuator, improved oil feed galleries and, for ease of maintenance, a side mounted alternator and rear mounted starter. The new gearbox can fit inside the minimum diffuser size permitted by the latest Le Mans Prototype regulations without any modifications, and the narrow viscous-coupling plate differential permits longer driveshafts. Options include a low loss bevel bearing for increased mechanical efficiency.

516 FRONT WHEEL DRIVE

Another state-of-the-art racecar transmission shown was Xtrac’s ‘516’ front wheel drive gearbox developed for the World Touring Car Championship and other worldwide touring car championships. Presented as a resin mock-up last year, the new transmission made it to this year’s show as a fully finished production gearbox, which has already been delivered to the launch customer.

The new gearbox makes use of reduced centre distance F1 derived gear ratios to minimize its mass, size and inertia, and the complete transmission weighs just 30.5kg. The gear-change system incorporates the latest polynomial barrel track design and a low inertia rack to improve gear-change response and driver feel.

The low positioning of the gear cluster lowers the centre of gravity and enables easy removal from the car under the chassis rail. The gear cluster is fully exposed when removed from the gearbox allowing quick inspection and ease of access for ratio changes.

Xtrac also displayed its 6-speed synchromesh gearbox developed specifically for high performance supercars. Intended for road use, such vehicles demand high levels of refinement and shift quality, which can be difficult to achieve with a bespoke design that may lack adequate engineering development because of ultra low volume budgetary constraints.

Xtrac’s solution is a highly refined ‘one size fits all’ transverse transaxle system, which can be specified for virtually any supercar, and is the result of a major engineering development programme. Its first application is the Brammo Rogue GT; the first 1,000Nm V12 supercar designed and built in the USA.

RELATED ARTICLES

Branded content: HL Klemove inaugurates first Local ADAS Radar Manufacturing Unit in India, marks a significant achievement in “Make in India” initiative

The inauguration ceremony was held in the presence of Vinod Sahay, President and CPO of Mahindra & Mahindra Ltd. and Dr....

BluWheelz to 'Green Up' logistics sector

With their EVs-as-a-service solution, the startup is playing it smart with costs and looking to electrify the entire seg...

BRANDED CONTENT: Spearheading the EV revolution in India

Jio-bp is a joint venture between Reliance Industries and BP PLC where both entities have married international expertis...

By Autocar Pro News Desk

By Autocar Pro News Desk

27 Feb 2007

27 Feb 2007

5140 Views

5140 Views