2012 Lightweighting Special: ASP pushes TPV tech for sealing systems

The Gajrola plant will be dedicated for the manufacture of thermoplastic sealing systems that are recyclable and 30 percent lighter than EPDM.

Thermoplastic vinyl (TPV) technology scores over conventional EPDM sealing systems in terms of product performance, cost and weight, says director Jagratan Singh Anand. TPV sealing systems can be used in windshields, doors, mirrors and roof ditch to prevent air, noise, water and dust from seeping into the vehicle.

The Gajrola plant will be dedicated for the manufacture of thermoplastic sealing systems that are recyclable and 30 percent lighter than EPDM. Hence, they help reduce total vehicle weight and in turn augment fuel economy. This is significant as conventional EPDM cannot be recycled; moreover, OEMs today increasingly face the challenge of producing vehicles using recycled products. While the conventional EPDM compound contains carbon black and is black in colour, TPV does not require any carbon black for compounding and can be produced in any colour as desired by the customer.

Further, metal carriers can be replaced with PP (polypropylene) when using along with TPV and compared with conventional EPDM plus metal carrier parts, TPV plus PP parts are much more lightweight. For instance, the replacement of the inner/outer waist-belt with a PP+TPV waist-belt. TPVs also fulfill the OEM requirement of weather resistance as they pass the necessary ozone, ultra-violet stability and hot and cold weather resistance tests. The technology also accrues in savings in terms of moulding and trimming costs as thermoplastic moulds are flash less and curing time is half of that in conventional EPDM moulding processes.

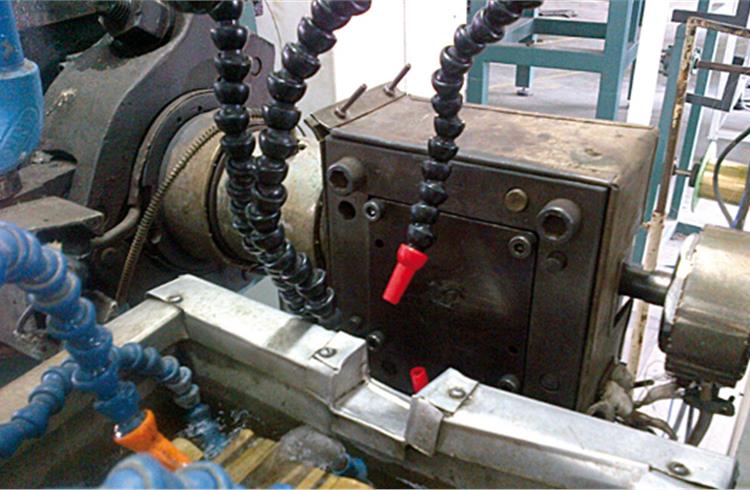

Besides, the cost of producing the part in TPV is lower as the EPDM involves use of microwave ovens and hot air ovens to cure EPDM rubber. In TPV, the raw material comes out of the extruder in molten form and is cooled down by water into the desired shape.

Products can be offered without flocking by using slip coat which is extruded during the initial extrusion process, which further reduces the cost of the product, says Anand.

ASP's major customers include Tata Motors, Mahindra & Mahindra, Eicher, Volvo and Ashok Leyland. The Tier 1 supplier has already invested Rs 20 crore in its new TPV technology, primarily through internal accruals, and is targeting a topline of Rs 120 crore in the current fiscal, an uptick from the Rs 100 crore it posted in FY’12 with the new products.

It has acquired the new die and head processing tech from a Japanese consultant and various other technologies from its JV partner Standard Profil of Turkey. Standard Profil is the second largest sealant producer in Europe for passenger cars and ASP plans to leverage this strength to enter the car market this year. It is in talks with two carmakers – one an American and the other a European – for this. The OEMs are currently auditing ASP's facilities for this operation.

With new orders in the pipeline, ASP plans to expand its production capacity for TPV products by adding an additional three lines besides the two already installed for which an investment of Rs 5 crore will be required.

Marketing director Rishi Anand says a new manufacturing facility will also go on stream in the first quarter of 2014 at Dharwad in Karnataka to meet the EPDM requirements of Tata Motors and other OEs in the region. Furthermore, ASP has recently begun producing automotive hoses at a separate unit in Gajrola for radiators, heat, air and water requirements of vehicles and plans to grow this business going forward.

SHOBHA MATHUR

RELATED ARTICLES

Strong support for EV ambitions

New policies and initiatives reflect the government's comprehensive approach to driving industrial growth, fostering inn...

Branded content: HL Klemove inaugurates first Local ADAS Radar Manufacturing Unit in India, marks a significant achievement in “Make in India” initiative

The inauguration ceremony was held in the presence of Vinod Sahay, President and CPO of Mahindra & Mahindra Ltd. and Dr....

BluWheelz to 'Green Up' logistics sector

With their EVs-as-a-service solution, the startup is playing it smart with costs and looking to electrify the entire seg...

By Autocar Pro News Desk

By Autocar Pro News Desk

31 May 2012

31 May 2012

3548 Views

3548 Views