The cool side of manufacturing

Industry 4.0 will transform the whole value chain from market research to engineering, testing, production planning, production and services.

Meeting old friends is always pleasurable. In some cases, especially when you haven’t heard from each other for some time, it can also be pleasantly surprising. Such a pleasant surprise happened to me a couple of weeks ago when I went back to see old friends in Stuttgart, Germany. One of them, Peter Fröschle, used to be in charge of alternative energy drives at Mercedes-Benz. We had not interacted much during the last 5-6 years and in the meantime he had become the CEO of Arena2036 (Active Research Environment for the Next Generation of Automobiles), a new initiative by the German government, various research organisations (University of Stuttgart, Fraunhofer, DLR, etc.) and a number of companies (Daimler, Bosch, BASF, Bär, Siemens, Festo, Kuka).

Arena2036 is one of the German avatars that drive Industry 4.0, the smart manufacturing approach that combines physical systems and the internet and that will lead to a dramatic improvement in sustainability, quality, and productivity. Peter’s teams are a mix of academic researchers and company employees who on average spend at least three days a week working together in the centre. Areas of focus of the teams are intelligent lightweighting of vehicles, driving the next level of digital production, building fenceless factories in which smart robots interact with humans seamlessly, and working on aligning the technology of the future with the role and resulting needs of human operators. Needless to say, I relished the afternoon that I got to spend with him and his new ‘toys’.

MAXIMISING INDUSTRY 4.0

Industry 4.0 can be understood as the full integration and digitalisation of the industrial value creation chain. It is the industrial equivalent of the digital transformation that has already impacted our lives via cloud data, apps, wearables, mobile devices, new business models such as car sharing, smart homes,

e-commerce, contactless pay and home robots. Through technology the real and virtual world grow together to cyber-physical systems, humans and machines start interacting to a degree that was unthinkable before the advent of modern communication technology.

Players in smart manufacturing are many. Infrastructure and technology providers such as Telcos, Cisco, Amazon, cloud computing and big data companies are focusing their attentions on smart manufacturing as are key industrial players like the ones mentioned above. Their aim is in some sense attaining the ‘holy grail’ of manufacturing.

Industry 4.0 will enable us to build individualised or mass customised products via very flexible production; it will integrate customers and value adding partners into the value creation process; couple production and high value services and last but not the least lead to a dramatic improvement in cost, efficiency, quality and sustainability. In short, it will transform the whole value chain from market research to engineering, testing, production planning, production and services.

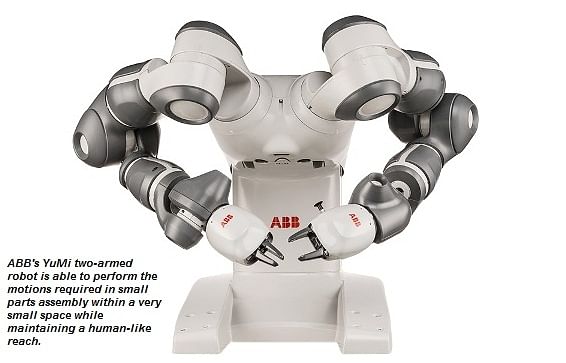

Advanced technologies such as robotics, big data, cloud computing and cyber security, a skilled workforce and resource efficient systems are key elements of smart manufacturing. Smaller, more intelligent robots can operate seamlessly with humans via new sensors and takeover a bulk of the standard work processes in the factory. Advanced and intelligent materials will enable lightweighting as well as crash optimisation. New manufacturing technologies such as 3D printing will shorten lifecycles and allow for customisation. Big data will enable predictive maintenance and a better integration with sales forecasts as well as suppliers. Resources and costs will be optimised by new technology and a skilled workforce is necessary to thrive in this brave new world of manufacturing.

TRANSFORMING MANUFACTURING

Whether it is the Mercedes C-class rear axle that is built with human robot collaboration, ABB’s two-armed robot YuMi with its flexible hands, parts feeding systems, camera-based part location and state-of-the-art robot control, or many other examples that can be found across the globe, the journey towards Industry 4.0 has started and transformed manufacturing from a routine operation into a hotbed of innovation. Germany started its efforts towards Industry 4.0 in 2011 (soon followed by national initiatives in France, Sweden, Belgium, the Netherlands, Austria as well as at the EU level), the US followed suit in 2012 with initiatives around the ‘Industrial Internet’ in 2012 and Japan concentrated its efforts around ‘Connected Factories’ in 2015. With significant resources behind these initiatives, we are likely to see a complete transformation of the value creation process over the next 10 to 15 years.

As efficiency improves by up to 30 percent according to a recent Roland Berger study, as labour content in manufacturing will be further reduced and quality further improved, as small batch production becomes feasible not only for nimble Indian players but also for global behemoths, key competitive advantages that India has today in manufacturing will come under pressure. India needs to take the challenge of Industry 4.0 head-on by adopting new manufacturing methods and technologies, doing small scale experiments, pushing the envelope in achieving Industry 4.0 via frugal means, and by investing in workforce skill upgradation.

Companies need to identify opportunities based on customer needs and the opportunity for differentiation, disruptive new technological solutions and a thorough assessment of own capabilities. Levers need to be quantified and a road map of building blocks identified to drive a potentially multi-year journey towards smart manufacturing. Smart manufacturing needs to be driven from the top and it requires significant cultural change in terms of both improved collaboration of internal cross-functional teams as well as improved co-operation with external partners (see the Arena2036 example above).

Industry 4.0 will support an upgrade of the ‘Made in India’ brand by enabling companies to remain cost effective, provide good quality, create safe work environments and be innovative. Help from the government is needed in the areas of infrastructure, grants for research and industry-academia collaboration, etc. Many of the necessary points have been identified in the National Manufacturing Policy of 2011 as well as the current ‘Make in India’ initiative. Execution needs to be driven with priority and potential successes quantified and clearly communicated.

The fourth Industrial Revolution is here and it is waiting to be leveraged by Indian entrepreneurs and their teams. Manufacturing has become an exciting hotbed of innovation ready for the ‘injection of Indian intelligence’. Let’s make it happen.

This exclusive column was published in Autocar Professional's 11th Annversary Issue (December 15-2015)

RELATED ARTICLES

Software Ages Faster Than the Car: The Bill Nobody Budgeted For

The Promise Was Longevity. The Invoice Is Just Arriving.

India’s Auto Boom Is Outpacing Road Safety: Why Road Safety Isn’t Scaling with Vehicle Growth

Even as roads improve and vehicles become safer, India records some of the highest road crash fatalities globally: aroun...

Union Budget 2026–27: Shaping India’s Manufacturing Future

Collectively, the six Kartavyas outlined in the Union Budget 2026–27 create a stable and forward-looking policy environm...

01 Feb 2016

01 Feb 2016

10234 Views

10234 Views

Arunima Pal

Arunima Pal