Technical tour de force

At the TechShow 2023, in Germany, Tier I component maker Continental showcased a host of products from the vehicle to the cloud future technologies for the mobility ecosystem.

It’s no secret that connectivity and digitalisation are advancing rapidly in the automotive ecosystem and even tech savvy global Tier I component players like Continental are aware of it. The global economic and financial crisis in 2008/2009 presented Continental with several challenges including bringing in change at all levels, especially the rapid transition from an aging technology application to new age technologies.

The task of doing so needed more than just a blueprint in an era that was still associated with losses when big changes took place with the impact of Covid-19 on global businesses.

However, it was new opportunities in emerging electric mobility, automation and autonomous driving technologies that have played an increasingly important role in widening Continental’s product offerings in the past few years.

That the company was serious in intent and wasn’t planning to just sit on its laurels, the initiative to change with an open mind was stressed several times and it was clearly evident at the elaborate TechShow 2023 in Germany, last month.

The message was clear — Continental is moving forward with an ambitious goal: To transform itself from a profitable supplier of components to OEMS to a full-solution services provider and play the role of an OEM itself, in selected areas of the automotive ecosystem.

The future forward plan has been in the making for a couple of years and the comprehensive exercise involves the three core pillars of the brand represented by ContiTech, Continental Automotive and Continental Tyres respectively. This move aligns perfectly with Continental's global expansion plans and ambitions to lead in digital businesses.

Moving towards automation

Common to the scheme of things, automation sits on top of the agenda. As digitisation and automation go hand-in-hand, several new business opportunities have been identified — among them is the concept of automated valet parking solutions, semi-dry braking systems, L4 autonomous electric trucks and design and manufacture of automated robots for industrial and non-industrial applications.

Sustainability

Sustainability

The company is also actively pursuing sustainable solutions that include tyres made out of recycled materials and various types of fabrics made out of biomaterials like coffee shells. At the TechShow 2023, Nikolai Setzer, CEO and Chairman of the Executive Board of Continental Tires highlighted the key aspects of the company’s business direction and even launched the production version of the UltraContact NXT tyre that is made of up to 65 percent share of renewable, recycled and ISCC PLUS mass balance certified materials as part of its global unveil. The UltraContact NXT, available in 19 sizes and will be sold in the European market from this month. The tyre comes with maximum EU tyre-label performance certification.

Tyre retreading now part of fleet solution

Tyres are estimated to contribute up to 53 percent of the total operating costs for truck fleets and Continental is offering an innovative strategy for digital tyre management aimed at reducing fleet-related costs. By leveraging sensor technology, algorithms, and cloud connectivity, the company demonstrated the benefits of service-based tire solutions. The ContiConnect 2.0 product ensures real-time monitoring of tire inflation pressure, temperature, and mileage, allowing for timely maintenance and minimised vehicle breakdowns.

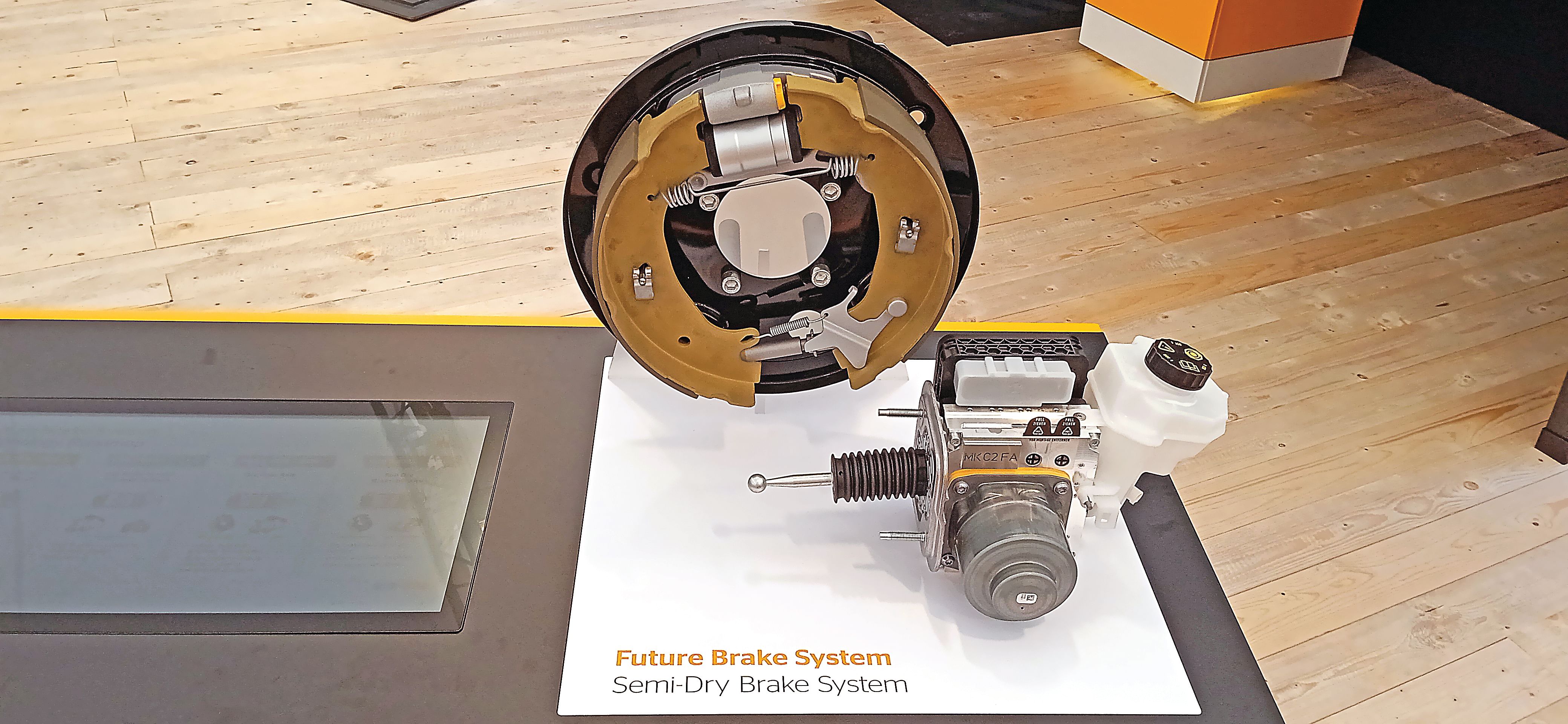

Future braking systems

Referring to some of the newer technology applications, Setzer said that vehicle architectures are undergoing fundamental changes towards zone-based set-ups and hence braking systems are witnessing a seismic change. According to him, they are becoming increasingly intelligent to meet the future needs and requirements of automated driving, electrification and digitalisation.

This aspect opens up the doors for introducing new technology applications that also fall in line with the company’s goal of Vision Zero, wherein the company says it is fully committed to improving traffic safety for everyone. The concept is “driving the development of Future Brake Systems (FBS) that are primarily used in vehicles with various architectures. The FBS gives the car manufacturer the flexibility to adopt smart actuator hardware where the software can be distributed on any electronic control unit to ensure safety redundancy and offering flexibility to the customers.

This aspect opens up the doors for introducing new technology applications that also fall in line with the company’s goal of Vision Zero, wherein the company says it is fully committed to improving traffic safety for everyone. The concept is “driving the development of Future Brake Systems (FBS) that are primarily used in vehicles with various architectures. The FBS gives the car manufacturer the flexibility to adopt smart actuator hardware where the software can be distributed on any electronic control unit to ensure safety redundancy and offering flexibility to the customers.

This means it is no longer necessary to mount the system directly on the firewall (usually in front of the driver) to enable mechanical fallback. Here, an electronic pedal offers flexibility in new vehicle concepts that may have different interiors or dimensions like a skateboard chassis of EVs, on which various body styles can be mounted. In fact, the FBS system has impressed a US-based automajor and Conti has already secured a US$ 2 billion order for it.

Autonomous mobility

The first commercial application of autonomous technology will come in trucks in four years and the concept will filter down to cars a few years later, said Setzer. For expanding the Autonomous Mobility business, Setzer said the company has inked an exclusive partnership with software specialist Aurora Innovation.

Continental and Aurora will bring autonomous trucking systems to the American market — as early as 2027. Continental will contribute not only the entire hardware system, but also a complete fallback system should anything go wrong.

On the other hand, automated valet parking (Type 1 and Type 2), and Level 4 Autonomous systems are being co-developed with Ambarella, an edge AI semiconductor company. Ambarella's energy-efficient System-on-Chip (SoC) family will be integrated into Continental’s Advanced Driver Assistance Systems (ADAS). Both partners are focusing on scalable full-stack systems for Level 2+ up to highly automated vehicles. These full-stack solutions take a multi-sensor approach, including Continental’s high-resolution cameras, radars and lidars, as well as the associated control units and the required software.

Software driven vehicles

According to various analysts, the market volume for software-based vehicle functions and services is expected to reach US$ 640 billion by 2031. "At Continental, we offer hardware, software and service modules to get the software-defined vehicle on the road together with our customers. We are shaping the entire ecosystem from the road to the cloud and, with data-driven development, testing and validation tools or solutions for cyber security, also ensuring that we close the circle from virtual to real," says Gilles Mabire, CTO of Continental Automotive.

More investment in Hydrogen tech

The ground realities related to energy self-sufficiency has prompted ContiTech to focus more on hydrogen technologies. Using its material expertise, the expansion of the hydrogen solution range will be a systematic approach, says Contitech’s CEO Philip Nelles. The company is working on hose line systems for service station applications and on innovative surface materials for storage tanks.

Continental unveiled its unique solutions for hydrogen gas stations. Their pioneering hybrid hose solution, designed to withstand high pressures and low transport temperatures, enables efficient and safe refueling of hydrogen-fueled vehicles. This innovation symbolises a key step in transitioning energy-intensive industries and heavy-duty transport towards a sustainable future.

In-car technologies

New technologies on display included facial recognition, scenic view HUD display new weight saving polymer pipes for EV cooling, innovative solutions for circuit board cooling with easy access for service.

Repurposing infrastructure

One of Continental’s oldest manufacturing units (originally a foundry) at Rheinbollen, an hour’s drive from Frankfurt, has been making brake calipers and will also make automated mobile robots (AMR) as part of the captive diversification approach. Work began two years ago in this 30,000 sq-ft unit that employs 600 engineers. Approximately 5,000 sq-ft has been allocated for R&D facilities, prototyping and series production of AMRs. The Gen II AMRs are already being used in China and Slovakia. Applications for these highly agile modular designed robots that use state-of-the-art technologies like sensor driven laser cameras, obstacle detection capabilities that can carry loads up to 1.2-tonnes are suitable for industrial material workflow, agriculture, horticulture among other practical usages.

This feature was first published in Autocar Professional's July 1, 2023 issue.

RELATED ARTICLES

Tata Motors, V.O. Chidambaranar Port Authority Sign MoU to Deploy 40 Hydrogen Trucks

India's largest commercial vehicle maker will conduct trials before phasing in 40 H2 ICE prime movers at Tuticorin port ...

EMotorad Adds Medium Frame and Citrus Blue Colourway to Its Ranger Electric Cycle

The Pune-based electric cycle brand adds a second frame size and a fresh colour option to its most popular model, wideni...

SEDEMAC Mechatronics IPO Price Band Set at ₹1,287–₹1,352; Subscription Opens March 4

The IIT Bombay-founded automotive ECU maker launches an offer-for-sale of over 8 million shares, targeting listings on b...

13 Jul 2023

13 Jul 2023

4787 Views

4787 Views

Sarthak Mahajan

Sarthak Mahajan