Volkswagen APP550 electric motor to power Mahindra Thar.e, BE EVs

The next-generation motor has significant step up in performance as well as thermal efficiency; Volkswagen could explore localising the e-motor in India if combined Mahindra EV and future VW-Skoda EV volumes are good.

In April this year, Volkswagen revealed its next-generation electric drive unit for the rear axle – dubbed the APP550 – for its ID. family of EVs. Mahindra & Mahindra has now adapted the APP550 motor to its INGLO platform and this motor will power its entire range of BE EVs, as well as the Thar.e when it eventually makes it into production. The first Mahindra to use the APP550 motor will be the BE.05 that is due for launch in 2025.

The tie-up with Volkswagen for components from its MEB platform is proving to be a trump card for Mahindra as it gets access to the latest technology from a global EV giant. The APP550 rear-wheel-drive motor will make its production debut in the VW ID.7 at the end of this year.

Volkswagen's new powertrain has an output of 210kW with a maximum torque of around 550 Nm – depending on the vehicle’s gear ratio. The significantly higher torque in particular ensures superior power development – both from standstill and at higher speeds.

Volkswagen's new powertrain has an output of 210kW with a maximum torque of around 550 Nm – depending on the vehicle’s gear ratio. The significantly higher torque in particular ensures superior power development – both from standstill and at higher speeds.

VOLKSWAGEN APP550 E-MOTOR: 210kW and 550 Nm

The new APP550 electric motor delivers 210kW (286hp) and a maximum of 550 Nm of torque, a significant step up from the previous motor that produced 150kW (201hp) and 310 Nm of torque.

The current is a decisive factor for the power of an electric drive unit, for which Volkswagen employed an improved inverter, which is able to supply the high phase currents needed for greater power, acting as the controlling ‘brain’ in the powertrain.

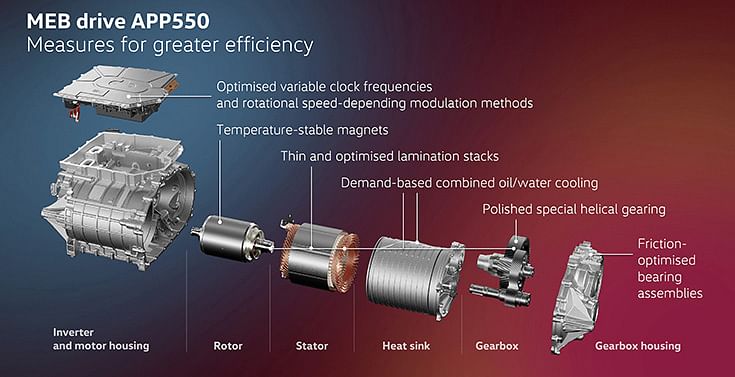

The APP550 electric drive unit achieves its higher torque output thanks to an enhanced stator with a higher effective number of windings and a larger wire cross-section. Additionally, the rotor comes equipped with more powerful magnets that have a higher load capacity. The electric drive unit also required additional reinforcing to withstand the higher power and torque outputs.

Thermal management is key for higher efficiency of an electric drive unit – the APP550 motor operates without an electrically driven oil pump, and is instead able to independently cool itself via the gear wheels of the gearbox and specially formed components for oil supply and distribution. The heated oil is cooled by the vehicle’s coolant circuit, which keeps the drive at operating temperature. The outside of the stator is equipped with a water heat sink.

In order to increase the efficiency of the electric drive, Volkswagen optimised a number of components in the powertrain, including the thermal management system.

VOLKSWAGEN COULD LOCALISE THE APP550 E-MOTOR IN INDIA

If the combined volumes of Mahindra EVs, and future Volkswagen and Skoda EVs (which will use the same motor) are good, VW may look at localising the motor.

Volkswagen has stated that though it is open to supplying to other automakers in India, the current focus is on developing the partnership with Mahindra & Mahindra, which is likely to be the sole customer here (outside of the VW Group) for the APP550. This state-of-the-art motor promises class-leading performance and efficiency and will be a huge competitive advantage for Mahindra.

ALSO READ: Production-spec Mahindra BE.05 electric SUV teased

Mahindra to launch INGLO-based EVs with BYD cells, Valeo motors

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

16 Sep 2023

16 Sep 2023

17772 Views

17772 Views

Autocar Professional Bureau

Autocar Professional Bureau