Tata Motors launches a raft of eco-friendly buses – electric, hybrid, fuel cell and LNG

In line with its plan to be future-read, Tata Motors has launched a range of electric and hybrid buses, a fuel cell bus and also some powered by alternate fuels.

Tata Motors today rolled out a stream of public transportation products at its Pune plant, all of them showcasing the manufacturer’s focus on smart and green technology and new mobility solutions.

The company launched the electric Starbus (9-metre and 12-metre versions), and Starbus Hybrid (12 metre) buses and also displayed a range of smart buses for green cities powered by alternate fuels.

Tata Motors, which is among the world’s top 10 truck and bus manufacturers, also showcased India’s first fuel cell bus (12m), an LNG-powered bus (12m), and an 18-metre-long articulated bus, all of them developed indigenously.

Ravindra Pisharody, executive director – Commercial Vehicles, Tata Motors, who was present at the launch, said: “At Tata Motors, our aim is to not only comply with emerging regulations of clean and green emission but also be ahead of the requirements. We have consistently been developing and manufacturing products that can contribute to CO2 reductions across all road transport segments and with early investments in new technologies, we are geared up to further strengthen our market leadership. With our new range of future-ready buses, we will continue to play an active role in mass public transportation, with a commitment towards striking the right balance between sustainable growth and profitability. We will work closely with government and regulatory authorities to intensify its efforts at tackling pollution, focusing on building alternative transport fuels and infrastructure, for smart cities of tomorrow.”

Hybrid-Electric Starbus: The indigenously developed Hybrid-Electric Starbus uses diesel and electric motors in series hybrid mode to propel the vehicle that complies with UBS-II (Urban Bus Specifications), AIS 051 (Automotive Industry Standards) and CMVR (Central Motor Vehicle Rules) standards.

The bus runs on electric mode producing zero emissions and is BS IV-compliant in diesel mode. It is built on a modular chassis, with electronically controlled air suspension systems (ECAS) at the front and rear, and has electronically controlled braking systems and an automatic transmission.

The Hybrid Starbus uses new-generation lithium ion phosphate batteries (Prismatic Cell) and can run without external charging infrastructures, due to integration of on-board charging with energy storage. While the batteries are re-charged by running of the diesel powertrain, the system also regenerates braking energy through an advanced electronic braking system.

The technology makes adoption of such advanced buses hassle-free, without investing in high cost of charging stations at bus depots or en route, offering operators much-needed range and flexibility to shift bus routes as per demand and need. In certain driving modes, regenerative braking is used to capture lost energy and charge the battery.

Tata Motors says the Hybrid Starbus offers substantial improvement in fuel economy compared to a conventional bus. The buses series hybrid technology offers the lowest cost of ownership, with around 25-30% fuel savings in comparison to conventional buses. The bus also runs on pure electric mode for around 30-35% of the total travel distance.

Fuel Cell Starbus: Tata Motors first showcased the zero emission Fuel Cell (Hydrogen) Starbus at the Auto Expo 2012, which is claimed to be ideal for stop-and-go applications.

Compared with battery-electric vehicles — which recharge their batteries by plugging in — the combination of fast, centralised refueling and longer driving ranges make fuel cells particularly appropriate for larger vehicles, with long-distance requirements, or for operations with lack of a plug access.

Above: Guenter Butschek, CEO and MD, Tata Motors, and Ravi Pisharody, executive director – Commercial Vehicles.

In the Hydrogen Fuel-Cell bus, hydrogen is stored in a compressed form, combining with oxygen from the air to generate electricity, giving out water vapour as the only emission. This technology makes bus travel completely clean and silent on-road. However, like other electric vehicles (EVs), the Fuel Cell Starbus employs idle-off, which shuts down the fuel cell at stop signs or in traffic.

With the MoU signed between Tata Motors and ISRO in 2006, ISRO has played an instrumental role by supporting Tata Motors with rich technology in producing, storing and handling gaseous and liquid hydrogen.

12m LNG Starbus: India’s first LNG bus is being pitched as an alternative to diesel and CNG power, providing benefits of lower carbon emissions and better fuel economy while lowering operating costs and emissions significantly.

Lighter in weight compared to buses powered by conventional fuels, Tata Motors’ LNG bus has enhanced levels of payload.

Due to the high energy density of LNG, the LNG-powered Starbus has a longer range of over than 700km in one filling. LPG powered vehicles also ensure better Noise Vibration Harshness (NVH) characteristics for passenger comfort.

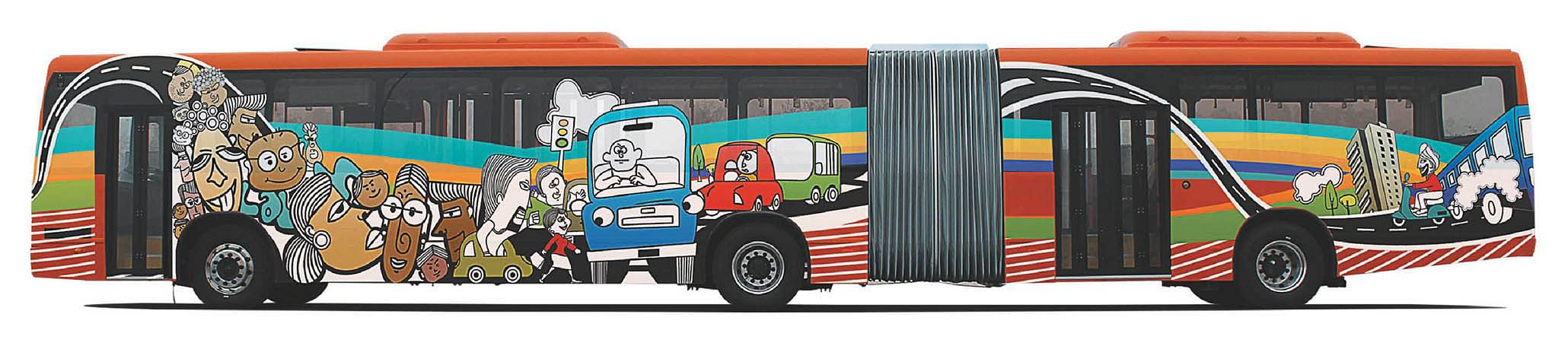

18m articulated bus: Tata Motors’ articulated bus is designed to carry more passengers (120+ versus 50-80), owing to its body design. This can in turn scale up pphpd (passengers per hour per direction) without increased investments in infrastructure.

The main benefits of an articulated bus over the standard bus are rapid simultaneous boarding and disembarkation through more and larger doors, much larger passenger capacity more efficient, less staff per bus hence higher revenue per bus. Wider doors provide ease of access for differently-abled passengers and the elderly.

Articulated buses are most suitable for Bus Rapid Transit System (BRTS) as they have higher capacity and can thus carry more passenger per hour per direction.

Tata Motors currently designs, develops and manufactures its buses at its plants in Pune, Dharwad, Pantnagar and Lucknow. Besides its partnership with ACGL of Goa for bus bodies, Tata Motors also has a joint venture with Marcopolo SA of Brazil for fully built bus (FBV) solutions. The company says it approach of manufacturing FBVs (Fully Built Vehicles), meets the government’s new norms in terms of safety, fuel efficiency and wider bus gangways, with the flexibility to be powered by both CNG and diesel.

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

By Autocar Professional Bureau

By Autocar Professional Bureau

25 Jan 2017

25 Jan 2017

24745 Views

24745 Views