Sedemac displays world-first sensorless ISG ECU at SIAT 2019

The company has developed the world’s first sensorless ISG technology that eliminates the need for hall effect sensors, conventionally used for ISG applications, thereby providing high temperature compliance, improved reliability and reduced system cost.

The Pune-based Sedemac, a budding supplier known for developing innovative powertrain control technologies, has a special focus on controls for small powertrains both for the on-road and off-road markets. The company’s long-term bets are aligned with emission reduction, improvements in fuel efficiencies, electrification, and improved user experience.

The company’s immediate interest is in the disruption of the starter motor industry. It is beginning to see application in the two-wheeler industry through its Sensorless Integrated Starter Generator (ISG) technology. The company will showcase the following products and technologies at SIAT 2019 at its display area (Stall No. 50):

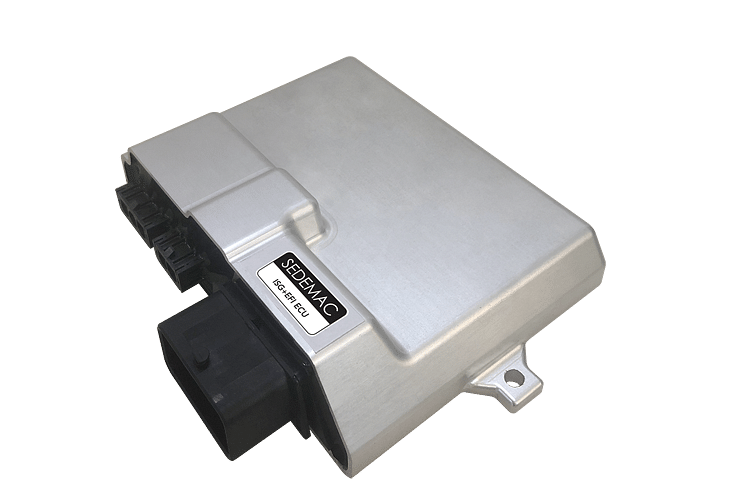

Sensorless ISG ECU: This eliminates the need for conventional starter-motor based engine start systems, offers instant and smooth engine start, improved reliability, and enables idle-stop-start feature. The company has developed the world’s first sensorless ISG technology that eliminates the need for hall effect sensors, conventionally used for ISG applications, thereby providing high temperature compliance, improved reliability and reduced system cost. The forward-looking ECU architecture enables integration of electronics of other control intensive technologies like EFI and AMT.

ISG + EFI ECU: ISG-EFI tech integrates ISG which eliminates the conventional starter-motor based engine start system, with control intensive technology EFI system together in a single ECU. Elimination of hall-effect sensor also results in simplified electric machine design. This ECU can be used in two- and three-wheelers with crankshaft mounted alternator.

EV controls: Sedemac has developed a suite of products for OEMs plunging into the EV space. The company provides a complete controls and power electronics solution-set for 48V electric vehicle (EV) and hybrid electric vehicle (HEV) systems. The portfolio includes motor controllers, battery management systems, and DC/DC converters.

Weber: This motor controls offering, Weber, is a product-series of Field Oriented Control (FOC) enabled BLDC motor controllers. Weber comes in two variants – Weber-S (pictured above) and Weber-D. While the former is suitable for lower power (~2 kW) applications, the latter designed for mid-power (~10 kW) applications.

Ursa BMS: The Sedemac-developed battery management application is for 48V lithium ion batteries. It has modern State of Charge (SOC) estimators. Ursa supports up to 14 cells in a series. It monitors cell voltages, battery pack temperature & battery pack current, to enable passive balancing, battery protection and battery state estimation.

OTTO Automotive application specific IoT platform: OTTO comprises a resilient internet gateway device, highly secure firmware and a sharp device management cloud. These devices come equipped with GNSS, cellular internet, and inertia sensor unit. They interact with on-board ECUs, Sedemac Device Management Service (SDMS), and data server via GPRS (2G) communication module.

Custom ECU: Custom ECUs are Model-Based Development (MBD) platforms with reliable hardware provided to OEMs, which allow them ease of development of robust and reliable designs with greater flexibility to develop their own applications. Through these platforms, Sedemac empowers the OEMs to execute their projects faster with a custom, production-ready, embedded (hardware + base software) solution, with an option to own and control the application specific software component (developed with Simulink / Target Link models).

Common-Rail Diesel Injection ECU: Sedemac will also display its indigenously developed Common Rail Diesel Injection ECU. CR-ECU is a part of an electrically operated high-pressure injection system, which significantly improves fuel efficiency. Sedemac’s CR-ECU provides access to the application layer to the customers, thus providing the flexibility to develop their own high-level application layer logic and protect their IP. It controls a multitude of actuators including the injectors, to provide torque throughout the demanded RPM range, and at the same time it meets the new stricter emission norms.

CR-ECU reduces emissions and noise-vibration-harshness (NVH) levels compared to the conventional mechanical injection systems. It runs highly complex control algorithms, ensuring that the engine runs clean and efficient in the full operating regime.

The company has developed CR-ECUs for LCVs, MCVs and HCVs for 2-, 3-, 4- and 6-cylinder, common-rail direct injection engines. Its natural progression towards IoT and automation tools makes it a preferred choice for commercial vehicles, passenger cars and diesel power gensets.

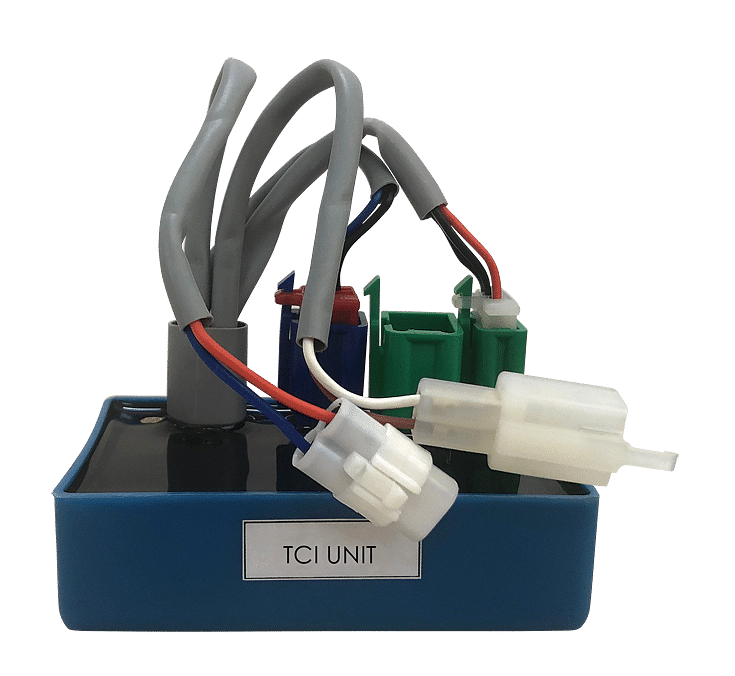

Smart ignition technology: Sedemac’s smart ignition tech enables precise execution of ignition timing in two- and three-wheelers (pictured above) through real-time dynamic estimation of load without the use of a throttle position sensor.

The technology leads to cost saving through elimination of throttle position sensor and associated wiring harness elements to better manage fuel economy, emissions, and performance. This technology is applicable to all small spark ignited engines.

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

16 Jan 2019

16 Jan 2019

24133 Views

24133 Views

Autocar Professional Bureau

Autocar Professional Bureau