Hyundai Motor India expands production capacity, plans 8 new models over next 2 years

The Korean carmaker states it will increase its production capacity to 750,000 units and has plans to introduce 8 new models including its first electric car for the Indian market.

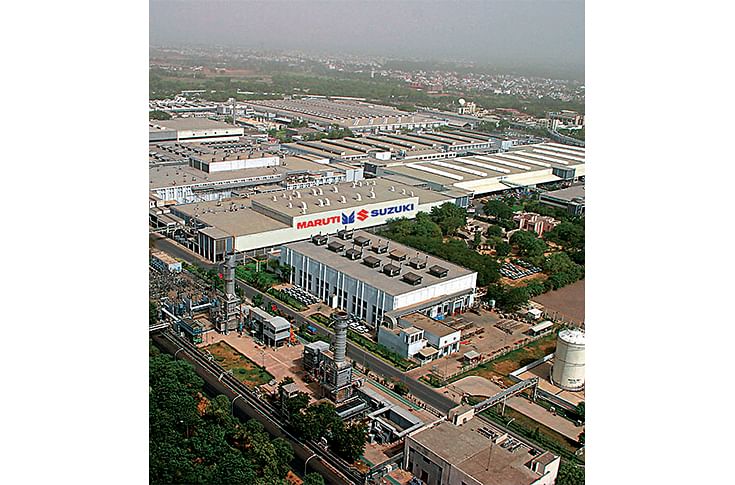

Hyundai Motor India, the country’s second largest car manufacturer today announced that its Chennai plant is future ready in terms of meeting the safety and emission norms well in advance before the mandatory industry implementation in 2019. The company claims its Mega manufacturing plant has adopted futuristic technologies, and it had achieved the milestone of becoming the fastest Indian automobile manufacturer to roll out 8 Millionth car in a span of 19 year and 9 months.

The manufacturing unit is spread across 535 acres and along with advanced Manufacturing 4.0 production equipped with over 590 - Generation 4 robots, quality and testing capabilities along with flexible engine plants to cater for India as well as global Market.

Hyundai Motor India states its plant is running at almost 100 percent capacity utilisation and aims to increase its production capacity from the current 700,000 units to 750,000 units per annum through value engineering and without any future investment.

The company states it is gearing up to introduce EVs in India and will start manufacturing them at its plant. It states that it is also working towards making BS VI engines, car and pedestrian safety tech along with airbags and ABS (Anti-Lock Braking System) as standard across its models.

Y K Koo, managing director and CEO, Hyundai Motor India said: “The Hyundai Motor Future ready Plant is a true expression of manufacturing excellence. Our journey in India started with the Hyundai Santro equipped with multi-point fuel Injection and Bharat Stage II technologies, the first in the industry and today through our smart and value engineering we have been producing the most Iconic and awarded cars from our plant. As a young and dynamic brand, Hyundai has implemented Smart Manufacturing 4.0 practices with focus on digitalisation, big data and data analytics to produce superior and zero defect cars with robust and fool-proof quality checks and assurance systems. At our plant, the seamless synergy between human intelligence and precision of machines is a combination of science and arts to create the finest cars that are loved by the customers across the world. “

"As we look forward to the journey of next 20 Years, we will strengthen our commitment to the Indian market by launching eight new products between 2018 – 2020 including an electric SUV,” Koo added.

The digitalised operations at the Hyundai smart plant captures over 1.2 billion data points across the manufacturing processes to gain insights to prevent and preempt errors for producing Zero Defect vehicles and ensuring plant safety. The global body build line has 100 percent weld automation along with flexibility to produce five models in a single line, which it claims is a testimony of its plants technical prowess.

The Chennai mega plant has been recognised by the Hyundai Motor Company and awarded as the number one performing overseas plant amongst entire group with ‘The Platinum Award for Excellence 2017’ and ‘Plant Safety Award 2017’.

The plant also has robust quality check systems - ‘Hyundai Integrated Vehicle Inspection Systems’ and ‘Hyundai Integrated Power –Train inspection Systems’ for full proof systems and three-stage inspection at factory, pre-delivery Inspection and delivery for complete quality assurance.

It also has incorporated environment-friendly measures and focuses on ‘Green Manufacturing’ with ‘Self Sustainable Resources’. There are 4 ponds spread across 15 acres for rainwater harvesting, and as part of its energy conservation initiative, it has installed LED bulbs that have not only brought down the energy consumption but also resulted in saving of Rs 13 crore per year in terms of electricity cost.

One of the water bodies at the site

In order to help its employees align their goals and skills with that of its own, Hyundai’s mega manufacturing plant is currently working on 4 core principles for its next 20 years of journey of excellence under the initiative – My Place My Pride (MPMP).

Currently celebrating 20 years of production and sales in India, Hyundai has also established itself as one of the largest car exporters since inception and currently exports to 88 countries.

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

By Autocar Professional Bureau

By Autocar Professional Bureau

27 Jul 2018

27 Jul 2018

20728 Views

20728 Views