Honda to make swappable EV batteries in India, sets up sharing service subsidiary

The Honda Mobile Power Pack e will be made in India; Honda Power Pack Energy India will offer battery sharing service for small mobility

A month after it announced plans to begin a battery sharing service for electric rickshaws in India, in the first half of 2022, using its all new portable and swappable batteries christened ‘Honda Mobile Power Pack e:’, Honda has set up an India subsidiary.

Honda Power Pack Energy India, Honda’s new subsidiary for battery sharing service, will offer battery sharing service for small mobility, which will accelerate the penetration of EVs by solving three key issues: limited range, long charging time, and high cost of batteries. It is planned to start battery sharing service for electric auto rickshaws (e-auto) from the first half of 2022 in Bengaluru, Karnataka and expand the operations in other Indian cities in phased manner.

Honda’s battery sharing service subscribers can avail the services from nearest battery swapping station located in the city to exchange the portable and swappable Honda Mobile Power Pack e: battery, with a fully charged one. By this convenient service, drivers need not to wait for charging and can get back on the road in marginal time.

The Honda Mobile Power Pack e: will be made in India. By utilising batteries made in India and accelerating electrification of small mobility, Honda Power Pack Energy India says it aims “to encourage the use of renewable energy and contribute to the carbon neutrality in India.”

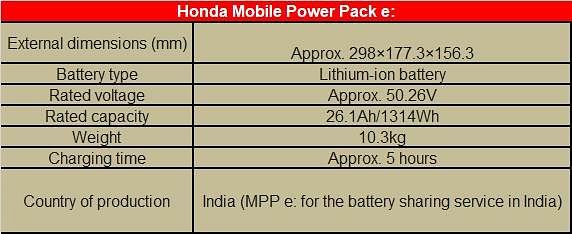

Honda Mobile Power Pack e: (MPP e:) is a portable and swappable lithium-ion battery comes with a capacity of more than 1.3kWh.

Key features

High versatility: In addition to mobility products, MPP e: can be utilized as a power source for a broad range of compatible devices.

High durability: By considering heat dissipation during continuous discharging, deterioration due to high temperature is prevented, and sufficient water resistance, vibration resistance and shock resistance are ensured under the expected normal operating environment.

Data utilisation: The built-in control unit recognises the conditions of the MPP e: and records the occurrence of all events. This data will be collected through the connector while MPP e: is charging and then utilised for the battery sharing operation and other secondary uses.

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

By Autocar Professional Bureau

By Autocar Professional Bureau

02 Dec 2021

02 Dec 2021

23378 Views

23378 Views