Drought and fire worsens chip shortage, TSMC sees it extending into 2022

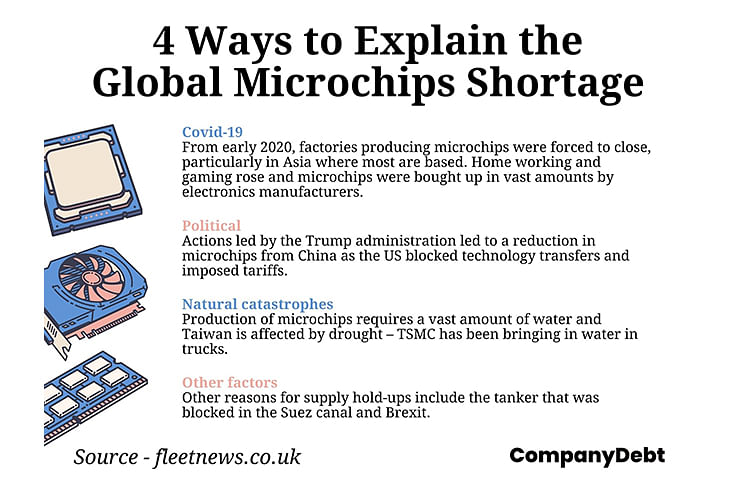

As the semiconductor shortage continues to affect auto production, fire and drought may have played a role in worsening the crisis.

Drought in Taiwan and fire at Japan’s Renesas Electronics earlier this year may have exacerbated the semiconductor crisis. One of the world’s largest semiconductor producers, Taiwan’s TSMC has said the shortages will extend into 2022 but the company reiterated that there has been no impact of the drought. Meanwhile analysts at IHS Markit estimate that the shortage will cost the industry $60 billion in lost sales this year.

While in India, the largest carmaker Maruti Suzuki’s September output takes a 60 percent hit, globally Stellantis is the latest to extend production halt by a week at several of its plants across Europe. Production at GM, Toyota, Volvo and many other key automotive plants have also halted production as a result of chip shortage. A spike in demand for electronic goods to cater to the pandemic lifestyle has led to a sharp rise in demand for these chips and resulted in acute shortage.

Reports indicate that the worst drought in Taiwan may have also impacted the production of semiconductor shortage. According to Taiwan Semiconductor Manufacturing (TSMC), the company reportedly uses 156,000 tonnes/day of water, though more than 85 percent is recycled. In fact, it is building a plant capable of treating industrial water to help increase use of recycled water for manufacturing chips. The company recently approved capital appropriations of approximately US$17,571.66 million (approximately NT$483,276.75 million) for various expansion initiatives Fab construction and installation of fab facility systems, R&D capital investments and sustaining capital expenditures. However, the good news is that heavy rains through August have boosted the water levels in most reservoirs across Taiwan.

When contacted by Autocar Professional, a TSMC spokesperson reiterated that the company’s production did not get impacted due to the drought in the country.

Another factor that could also have played a role in exacerbating the chip crisis is the devastating fire at Japan’s Renesas Electronics earlier this year. Though capacity at the plant is over 88 percent of the pre-fire levels, reports indicate that restoring full capacity may take longer than anticipated.

All these factors have also created a backlog of orders from the automotive sector. This no doubt has a particularly telling impact, given the extensive use of semiconductors in automotive production today. As per an earlier report on Autocar Professional, semiconductors form an integral part of a modern-day automobile ranging from passenger cars to buses and even two-wheelers. A passenger vehicle typically uses around 1,000 semiconductors . From driving basic things like digital radio tuners, electronic power steering, and door-and-mirror controls to complex mechanisms such as LED lighting, telematics and V2X communication for ADAS functionalities, these microprocessors are at the core of the vehicle, increasingly transforming it into an electronic-intensive piece of engineering. As vehicles transform into computers on wheels, it is microprocessors and semiconductors that are essaying the key role in the transition.

Furthermore, with the growing adoption of electric mobility, these semiconductors are further going to enhance their contribution and become deeply integrated in the neural networks of a vehicle to drive a predominant set of functionalities of what are seemingly the vehicles of the future.

Read More

Maruti Suzuki hit by chip shortage, September output to be down by 60%

How Jaguar Land Rover will beat the chip shortage

Semiconductor crisis to continue as chip makers perceive auto industry as low margin

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

01 Sep 2021

01 Sep 2021

35306 Views

35306 Views

Autocar Professional Bureau

Autocar Professional Bureau