Denso, one of the world’s leading automotive component suppliers, plans to make India its global manufacturing hub by 2025. The company, which is currently represented in India as six subsidiaries and a joint venture across six locations (Greater Noida, Haridwar, Manesar, Jhajjar, Bangalore and Pune), plans to invest about Rs 900 crore in the process of making India its global manufacturing hub.

Speaking to Autocar Professional on the sidelines of the Auto Expo Components Show at Pragati Maidan last week, Takashi Nagata, managing director, Denso International India, said: “Make in India has great relevance for our India operations. We will continue to expand on the front of powertrain products for the ICE vehicles. Making India our global manufacturing hub by 2025 is my dream.”

Commenting on the investment plans, Sunil Soni, deputy general manager, head of department, Sales Strategy Function, Denso International India (pictured above), added, “We plan to invest about Rs 900 crore in gradual phases as this will almost double up our current manufacturing capacities by 2025. As customers’ volumes will increase, we will also increase our manufacturing capacities. That’s how we would like to time it.”

The company, which has been present in India for close to 34 years now, had reported (including all six subsidiaries) a total consolidated turnover of Rs 46 billion in FY2016-17.

FOCUS ON FUTURE TECH

Stressing on the relevance of the Denso International India Technical Center, Nagata added, “We have been expanding the team at our technical center. The headcount currently stands close to 150 engineers. We will continue to expand the team as per the R&D needs.”

According to Nagata, the engineers at Denso’s technical center are also working on artificial intelligence (AI), mainly for projects that have India applications.

The company is set to register big benefits under the incoming BS VI regime. For example, it currently supplies fuel injection systems for two-wheelers. Denso officials estimate that the company’s production capacities have to be scaled up, in line with the estimated spurt in demand in the near future.

ELECTRIFICATION GETS PRIORITY

Nagata’s immediate priorities include focusing on future products under the vehicle electrification umbrella. “We need to work on the battery pack together with Suzuki and Toshiba. We should work on more products such as power control unit(s) and others for four-wheelers and two-wheelers. However, we will decide on the localisation and the timing, which is very important. It is very difficult to estimate what will happen by 2025. We are working on our mid-term plans currently.”

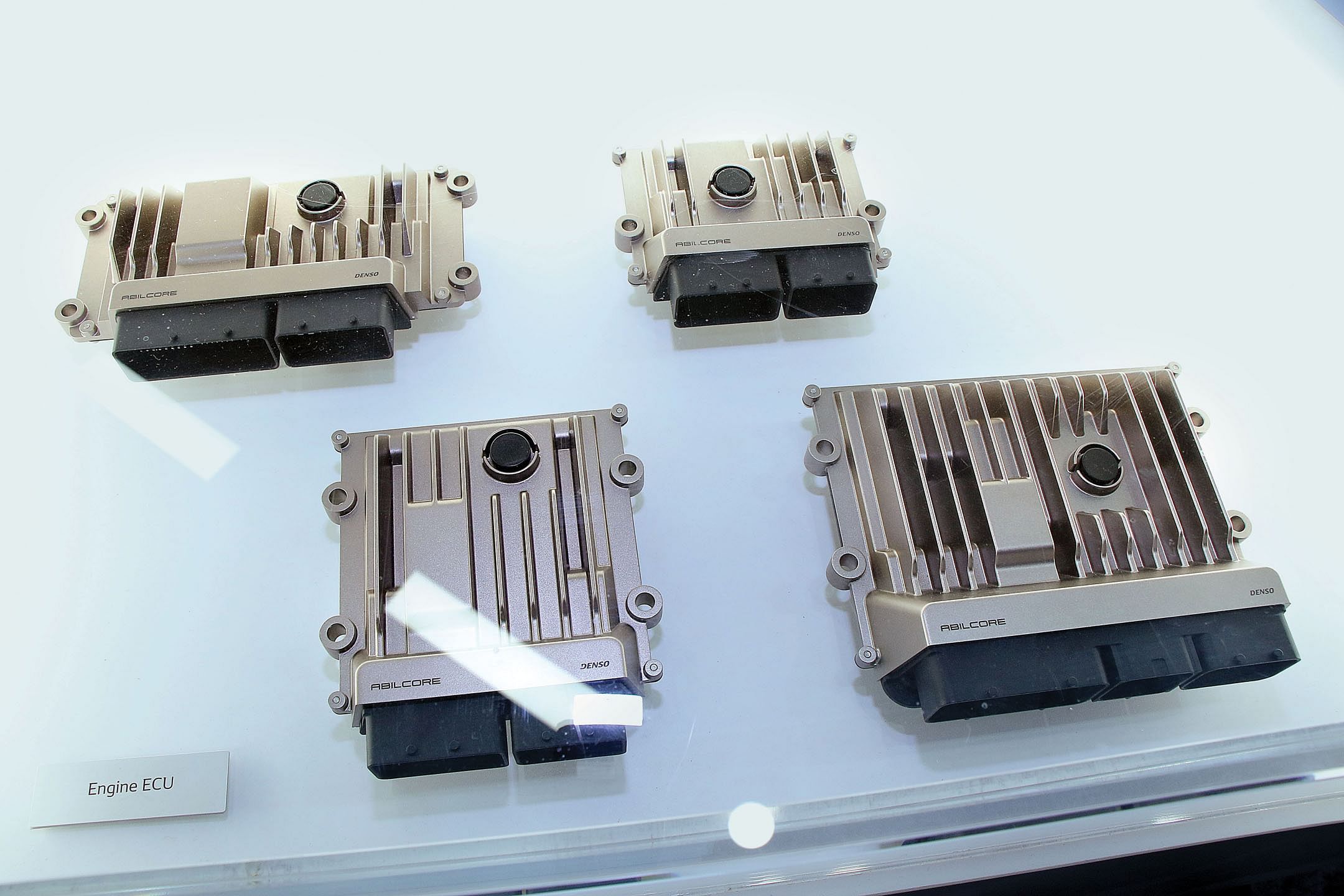

Engine ECUs suitable for advanced BS VI stages.

At the Components Show, Denso displayed future technologies that include stereo vision sensors and millimetre wave radar sensors, driver status monitors, engine ECUs suitable for advanced stages of BS VI emission norms, ceiling fan (that it supplies to the Toyota Yaris in global markets), motor generator, power control unit, battery ECU, emission control components, lithium ion battery pack and others.