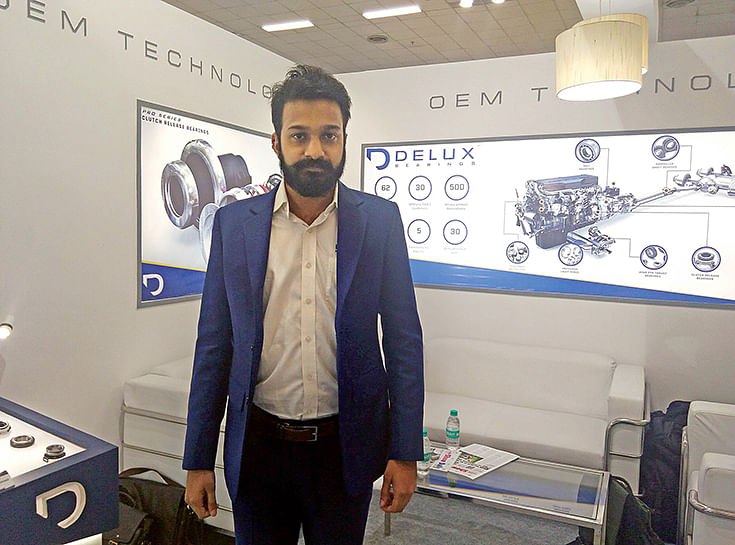

Delux Bearings' Rohan Rathod: 'Adopt lean management tools to be future-ready.'

Rohan Rathod, MD, Delux Bearings, shares his approach in his manufacturing facility for ensuring safe and sustained operations

May 1, which is commemorated the world over as International Labour Day, saw Autocar Professional conduct a special webinar to highlight the challenges and the solutions in manufacturing and skilling once the lockdown, now mandated till May 17, is lifted in India.

The panelists for the first webinar of May 2020 comprised Vijay Kalra, Head, Mahindra Institute of Quality and Ex-Chief of Manufacturing Operations- Automotive Division, Mahindra & Mahindra; Nikunj Sanghi, Chairman, Automotive Skill Development Council (ASDC); Ramashankar Pandey, Managing Director, Hella India Lighting; Rohan Rathod, Managing Director, Delux Bearings; and Ashim Sharma, Partner & Group Head - Business Performance Improvement (Auto, Engineering & Logistics), Nomura Research Institute.

Rathod, who heads Delux Bearings, the Mumbai-based manufacturer of clutch release bearings, ball bearings, pulleys and steering column bearings, brought an MSME (Medium & Small Scale Enterprises) perspective to the whole scenario. MSMEs are critical to the overall functioning of the automotive supply chain and also the most impacted in the current industry lockdown phase. Rathod is also one of the few in India who have made a soft start of their manufacturing facilities, as permitted by the local authorities. He shared his views and course of actions in ensuring the safety of his employees at the company facility and above all, the course of action towards sustained operations.

Lean management to be fit and future-ready

Speaking on some solutions that could be incorporated by the MSME sector in India, Rathod suggested some towards a gradual restart of an organisation. Among his many suggestions, he stressed on gathering and compiling as much data as possible on the pre-lockdown position, allocating the first few days for FY2020 book closure activity and revising worker manuals while also making sure that new heightened safety standards do not add more load to the already stressed financial condition of an organisation.

Lean manufacturing or the art of slashing waste, which customers are not willing to pay for, Lean manufacturing is all about minimalising waste within production and manufacturing systems while maximising productivity. It is based on several principles like the Japanese kaizen or continuous improvement. Among the many benefits derived by employing lean management methodologies include reduced lead times, reduced operating costs and improved product quality, all of which pay rich dividends to companies.

This approach is best defined in the famed Toyota Production System, which is now used the world over by both automotive and companies in other sectors. A recent example of successful lean management is the Toyota Production System being successfully deployed at Bangalore-based automotive springs manufacturer Stumpp Schuele & Somappa Springs to speedily ramp up production of face shields from 275 units a day to 5,500, which marks a massive 1,900 percent increase. And the new target is 10,000 face shields a day.

It is just these benefits from lean management that the young managing director of Delux Bearings is targeting. He said, ''While social distancing is the new norm, it should not violate the lean manufacturing norm. Re-use everything. We have a Re-Use Centre and have SOPs to reduce costs. Online learning, cloud-based training and listening are new people growth mantras."

Transparency matters even more now

Rathod also conveyed his concern for a proper communication stream with customers, company vendors as well as employees. "Complete honesty needs to prevail towards the employees in terms of the company's current financial positions, which would invariably boost their morale. In the post-Covid era, there is a need for companies to find the right balance between automation and employment because people's lives are involved."

He also spoke about the need to sensitise employees in a post-Covid work scenario. "In a post-Covid world, it is important for companies to sanitise but also sensitise. Sensitising the workforce is important. Do not take it for granted that the SOPs will be enough. Have Covid patrol teams and re-educate personnel.How about bringing error-proofing to hygiene practices? Companies should think about this in their own specific manner."

Being one of the few companies to restart operations, Rathod said that in the current scenario, it is much cheaper to run hand-to-mouth level of production than buffering stocks. This way he proposes to create new profit centres by offering excess capacity to others. Everyone should revalue the stream map to reduce production cost and take trials to reduce stocks.

From the past 30 days of lockdown, the entrepreneur has discovered the benefits of digital solutions like Google Suites and other communicating tools. This has further raised the need for fast-tracking of new technological solutions like remote monitoring, Industry 4.0 and a cloud-based document management system to enable the workforce to be future-ready.

Rathod predicted that for the next 3-6 months, the industry needs to brace itself for the challenging credit scenario, the cash crunch and more rigid SOPs. "Inter-company learning and collaboration is the path ahead for industry. We have to prepare ourselves for 3-5 months of low production," he signed off on a cautionary note.

Read More

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

02 May 2020

02 May 2020

17454 Views

17454 Views

Autocar Professional Bureau

Autocar Professional Bureau