ARCI develops new friction-reducing composite

The new commercially ready process for such nanocomposite coatings could be included in aerospace, automotive, and space sectors, where wear and corrosion are main problems.

A group of scientists at the International Advanced Research Centre for Powder Metallurgy & New Materials (ARCI), an autonomous R&D center of the Department of Science & Technology (DST) have developed a process for size-selective deposition of nanocomposite coatings which can reduce friction of these dynamic systems.

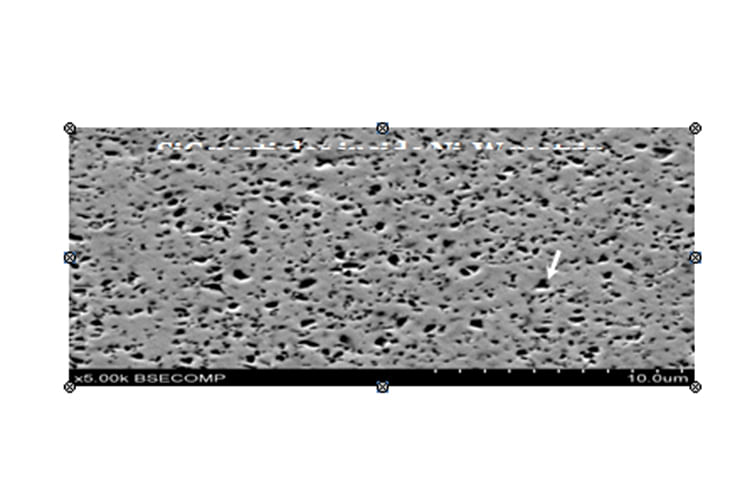

Schematic showing SiC particles incorporated inside Ni-W matrix during electrodeposition and image of Ni-W/SiC nanocomposite coating with uniform distribution of SiC particles

According to the scientists, the usual method incorporated in aerospace, defence, automobile, space devices involves a lubricating system which is expensive, complex and comparatively inefficient. Scientists at ARCI have found that nickel tungsten-based coatings with impregnation of particular sized Silicon Carbide (SiC) submicron particles using an economical and straightforward pulsed electroplating or electrodeposition process can provide an excellent combination of wear and corrosion resistance with the low friction coefficient and good oil retention capacity. ARCI scientists claim that the new coatings could reduce friction more and could withstand corrosion due to salt spray better than many similar wear-resistant coatings available in the market.

Size does matter

The coating could address the emerging need for coatings with low friction and wear. Nanocomposite coatings with hard particles inside a tough matrix result in the best combination of wear resistance and reduced friction. However, the size of reinforcement particles is a critical factor in deciding the friction characteristics. Too much variation in the size of reinforcement particles in composite coating results in premature failure of the coating due to stress concentration.

Electrodeposition also called as electroplating, involves the metal parts to be immersed in an electrolyte bath solution, in this case, typically prepared by dissolving crystals of Nickel (Ni) and Tungsten (W) salts in a mix of distilled water and other additives. A direct current (DC) is passed through the solution, and the resulting reaction leaves a deposit of Ni-W alloy on the piece being plated. During electrodeposition, a diffusion layer is formed at the cathode surface due to movement and deposition of metallic ions in solution.

For size-selective electrodeposition, pulse current (PC) electrodeposition – intermittent application of current is used in place of conventional direct current (DC) deposition. Pulsed currents of certain amplitude and duration helps in depositing coatings of desired properties, which would not be possible with conventional DC plating.

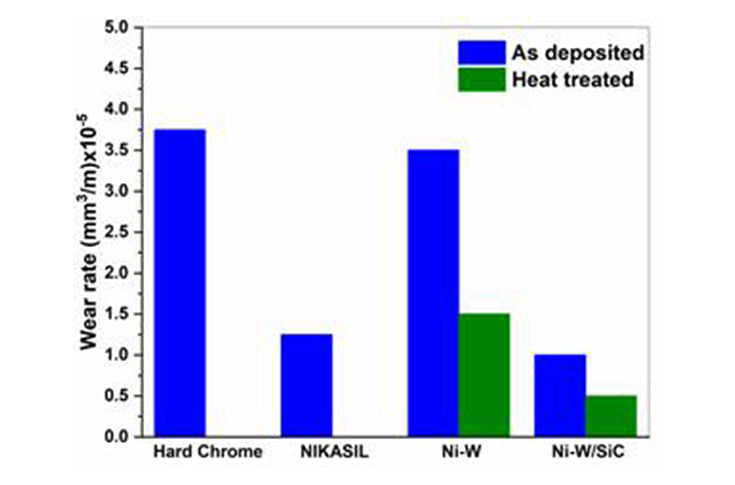

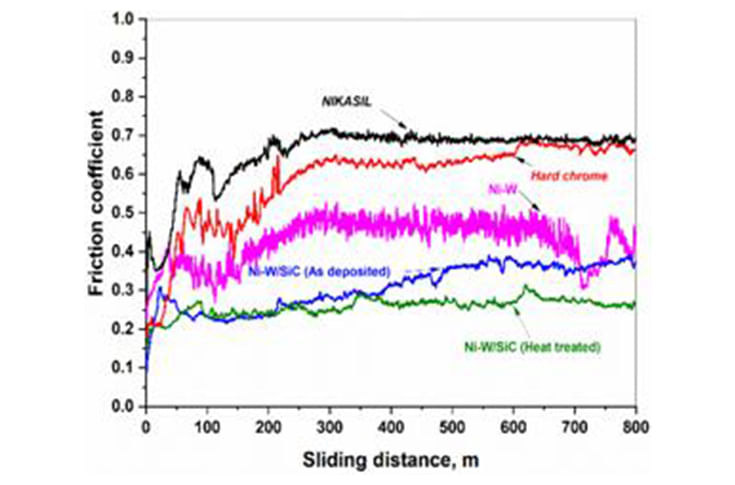

Nanocomposite coatings illustrating excellent wear resistance and lower friction coefficient when compared to NIKASIL and hard chrome coatings

The recent finding by ‘Engineered Coatings’ group at ARCI shows that, by careful selection of pulse parameters, reinforcing particles of a given size can be selectively and uniformly deposited in a metallic matrix. In this process, during electrodeposition, only particles having a size equal to or less than diffusion layer thickness can be incorporated into the nanocrystalline coating. The size of the diffusion layer thickness is controlled by changing the duration of the electric current pulse during pulsed electrodeposition. The process is suitable to many other composite coatings requiring reinforcement for various applications, including fuel cells, batteries, catalysis, and so on.

ARCI claims that the new nanocomposite demonstrated excellent tribological behaviour (science and engineering of interacting surfaces in relative motion, which includes principles of friction, lubrication, and wear) compared to other wear-resistant coatings such as NIKASIL (trademarked electrodeposited Nickel matrix Silicon Carbide) and hard chrome. These new coatings withstood 1000 hours of salt spray (corrosion) without degradation when compared to conventional wear-resistant coatings like hard chrome used in the automobile industry. The performance of new coatings was better in as-deposited condition itself. However, the wear performance can further be improved (doubled) when composite coatings are post heat treated.

Many opportunities and application avenues are available for such nanocomposite coatings, including aerospace, automotive, and space sectors, where wear and corrosion are main problems. The process is said to be highly economical without environmental constraints. The process has been patented and is ready for commercialisation through the industry.

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

By Autocar Professional Bureau

By Autocar Professional Bureau

18 Mar 2020

18 Mar 2020

14999 Views

14999 Views