Altigreen reveals indigenous electric drivetrain components for EVs at Auto Expo

The Bangalore-based start-up is in last-stage talks with a three-wheeler OEM to launch an electric cargo vehicle.

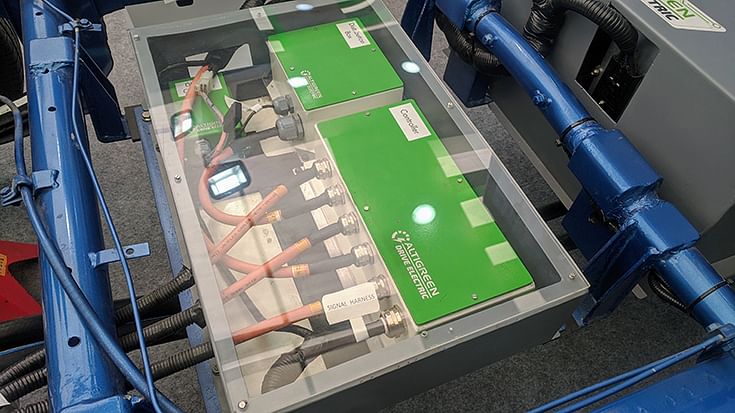

Bangalore-based Altigreen Propulsion Labs, which is into the design, development and manufacturing of electric drivetrain components including motors, controllers, power electronics and battery packs is showcasing its EV technologies at Pragati Maidan – Hall 7-FGH (Outdoor) Stall No. F2.

Altigreen has displayed its 90XT, a 500kg payload electric three-wheeler prototype, which offers a range of 125km on a single charge, taking less than four hours. The EV built on a conventional cargo-carrying three-wheeler platform can handle gradients between 17-18 degrees and its air-cooled electric motor generates a peak power output of 9kW.

The power electronics, distribution box, controller box and motor are all IP67 rated. While each of the drivetrain components is Type Approved, including having undergone EMI and EMC testing, the vehicle is currently undergoing vehicle-level homologation at certification agencies.

The company claims that it should be able to go to market in three months and revealed that it is closely working with three vehicle OEMs, one of which is set to launch a cargo-carrying electric three-wheeler under its own brand, but driven by Altigreen's solutions, in the next three months.

At Pragati Maidan, however, ithe company claims it is seeing huge response and getting inquiries into the complete product from not just India but delegates from countries like Tanzania and Kenya as well.

Speaking to Autocar Professional, Shalender Gupta, co-founder and CFO, Altigreen Propulsion Labs, says, "The response so far has been phenomenal."

Shalender Gupta: "This is a long-term game and we want to make sure we do it right with thousands of kilometres of testing on the roads as well as bench testing of our solutions in the lab."

Locally assembled e-three-wheelers

While it aims to primarily be a drivetrain technology provider, it is initially also taking orders for the completely assembled vehicles on a three-wheeler chassis. It has already received orders for 250 completely built-up units and another 5,000-6,000-odd are in the pipeline. Once the homologation is completed, company will start delivering these vehicles, assembled out of its plant in Whitefield, Bangalore. "All orders are from last-mile and fleet operators," Gupta said.

While it is already manufacturing and stocking drivetrain components at its facility where it makes 100-120 motors a month, Altigreen will only start vehicle assembly once homologation is completed.

"This is a long-term game and we want to make sure we do it right with thousands of kilometres of testing on the roads as well as bench testing of our solutions in the lab," Gupta said.

The 170XT is a Tata Ace-based cargo-carrier with a 17kW (peak power) liquid-cooled electric motor and a rigid e-axle for transporting higher load capacities.

Powerful LCV tech

Altigreen’s next prototype – the 170XT – is a four-wheeler cargo-carrier based on the Tata Ace, and gets a 17kW (peak power) liquid-cooled electric motor with a rigid e-axle for greater load capacities. The 170XT weighs 2T and can haul between 1-1.2T. While effective range will be dependent upon the size of the battery, Altigreen says it would recommend customers to opt for at least 100km, while it can offer up to 200km range in a single charge.

With 85% localisation of its electric drivetrain components including controller, distribution box, power harness, signal harness and DC-DC converter, Altogreen qualifies for FAME II subsidies.

With an 85 percent localisation of its drivetrain solutions, excluding the battery cells, Altigreen says its technology, when incorporated into a vehicle, will make it eligible to avail the subsidy under the FAME II. With a completely indigenous suite of power electronics including the DC-DC converter, power harness, signal harness integrated with sensors and contactors, power inverter and vehicle control unit, the company is well placed to take on the electrification opportunity the market is set to offer in the shared mobility, last-mile delivery and commercial fleet segments.

The company only be left with the battery cells and a few electronic components such as chips which continue to remain imported for everyone as there is no raw material source in India.

New manufacturing plant in the offing

Believing strongly that demand will pick up in the near future, Altigreen plans to set up a larger capacity plant in Bangalore which calls for Rs 40-50 crore in capex. "The new facility should be up and about in 12-15 months' time and will cater to OEMs, starting with three-wheeler companies," says Gupta. The company will then be able to produce close to 3,000 drivetrains in a single-shift pattern and 6,000 units over two shifts each month.

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

08 Feb 2020

08 Feb 2020

33627 Views

33627 Views

Autocar Professional Bureau

Autocar Professional Bureau