ACMA's Deepak Jain: 'It'll now be survival of the fittest and the need to collaborate to stay relevant.'

The ACMA president spells out, in no uncertain terms, the challenging situation the Industry auto component industry finds itself in right now.

The Covid-19 pandemic has challenged the global automobile industry like never before. In the Indian perspective, it is a double whammy for the industry which is already in the throes of a deep 18-month slowdown. As India Auto Inc grapples with the challenges of the swift transition to BS VI from BS IV, the move towards sustainable mobility, this pandemic has put further pressure on the already stretched resources for component makers.

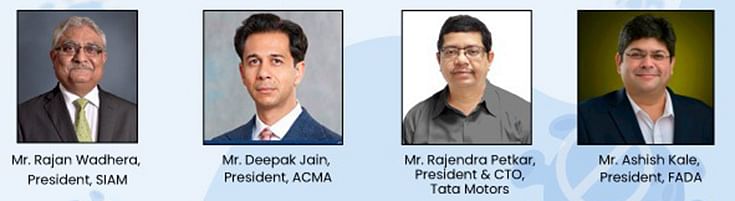

As one of the four panellists in Autocar Professional's webinar on 'Rising to a Challenge: Business in the midst of a pandemic', Deepak Jain, President, ACMA said, "Covid-19 has disrupted the entire world. There will be a new normal with reduced revenues. Everyone will have to fend for themselves. Like Darwin said, ‘It's survival of the fittest.’ Those who will survive will have to collaborate to stay relevant."

For the Indian component makers, the problems started much earlier as Jain further outlined, "India's component supply chain got disrupted from Jan 2020 itself after a 20-month slowdown. We were aligned and invested for the BS VI transition opportunity, taken debt, looked at forward plans to localise these technologies as a Make in India opportunity."

Need to localise

Can localisation be a way to tackle this double-trouble? After all, OEMs import quite a significant chunk of the BS VI parts. Speaking about the BS VI parts that are being imported, Jain mentioned that there wasn’t enough time to test and make critical parts in to meet the April 1 deadline. “In the short-term, there have beena lot of imports due to inadequate time for testing from mostly European companies, who might have manufacturing units in India. Going forward, it will be an extremely challenging time. Component companies are just managing to survive and there will be pressure on localising and engineering initiatives. Only for BS VI, we have no option but localise.”

Though the industry stands with the government in the hour of the pandemic, it has threatened the survival of the component manufacturers as there is a complete halt in the production and the working capital flow is hampered too. The situation is similar across Tier-1, Tier-2 and Tier-3 manufacturers and further exacerbates the condition. Jain outlined that, “ACMA has urged the government to give some relaxation on borrowing norms and statutory payments. We have not seen any economic bailout so far. Also, we have asked for extending the moratorium on payment of principal and interest. We are also seeking the support of SIAM and the OEMs to ensure minimal disruption of the supply chain"

Confidence boost for employees

That said, Jain highlighted that the focus at the moment is regaining confidence at all levels, especially the workers on the shopfloor and providing a safe and conducive environment for them, “Now, it's all about how do we survive this period. Covid-19 is not going away anytime soon. We have to adjust shopfloors to the new normal with a staggered approach. What will be key is to give confidence to the workforce to come back to the shopfloor."

Charting the future course

For him the operational mantra at the moment is, “Opening will involve ramping up with lean resources. The current situation has taught us the concept of remote working closely tied to trust in our employees. Collaboration, use of digital tools for effective functioning through remote working. We need to give confidence to our workforce to come back to the job. The safety aspect is key. In the process of rolling out set of protocols for ACMA members. Balancing seamless supply chains is a key challenge going forward.”

Along with that, affordability is also a key consideration that Jain feels component makers and OEMs alike need to focus on. "India is a price-sensitive market. A recovery now will be much later than H2. Need to do the right localisation, in terms of QCD. Supply chains looking for individual survival and using cash flow for that. So the overall perspective needs to be considered."

Collaboration and consolidation will be the way forward for the industry, according to Jain, as component makers across the country prepare to open their manufacturing plants and shopfloors once the lockdown is lifted and adjust to the new normal.

Tata Motors' Rajendra Petkar: 'Pandemic paving the way for significant collaboration opportunities.’

SIAM's Rajan Wadhera: Industry may see 50% sales decline over two years

FADA's Ashish Kale: Reviving auto industry vital as it has a multiplier effect on sentiment

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

12 Apr 2020

12 Apr 2020

21886 Views

21886 Views

Autocar Professional Bureau

Autocar Professional Bureau