ZF’s new lightweight, ultra-compact e-drive for cars has torque density of 70 Nm/kg

EVbeat concept vehicle with prototype of new 800-volt electric drive sets standards for compactness, lightweight and high efficiency

At its Global Technology Day in Friedrichshafen, ZF is showcasing the electric concept vehicle EVbeat, which is designed for maximum compactness, low weight, and maximum efficiency in real operation.

This concept EV houses the components of an e-driveline which have been optimised and combined into a holistic system. These include the 74kg lightweight and ultra-compact driveline with a torque density of 70 Nm/kg, holistic thermal management and cloud-networked driveline software. At cold temperatures around freezing point, the range in real-world operation increases by up to a third compared with current technology.

“Sustainable mobility is at the core of our corporate strategy,” explained Stephan von Schuckmann, member of the ZF Board of Management responsible for electrified driveline systems, among other things. “Based on an extremely efficient production vehicle, we are showing the potential that future electric drive components offer when we combine them into an even more efficient overall system.”

The ZF EVbeat concept vehicle is based on a Porsche Taycan and takes leading series technology from ZF and other market players as a benchmark.

“Our goal was to make this drive as compact and lightweight as possible while maintaining high driving dynamics and increasing efficiency in real-world operation,” said Dr Otmar Scharrer, Head of Development for Electric Driveline Systems at ZF. “In terms of torque density, we are at the top of the podium when we compare ourselves with e-drives for passenger cars currently available on the market. At the same time, we paid strong attention to the sustainability aspect during development.”

Fewer components help reduce power pack weight

The electric motor works without heavy rare earth elements and the thermal management system does not use fluorine-based refrigerant. The reduced number of components and the overall reduction in system weight – by one-third for the electric drive and thermal management system –

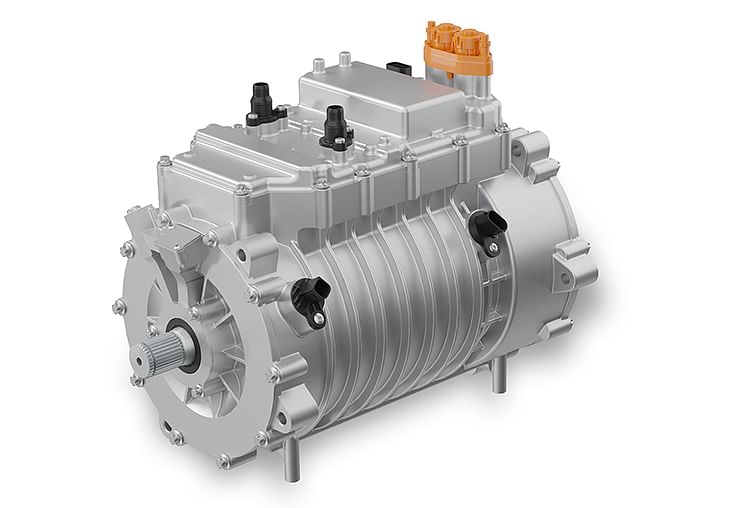

The EVSys800 is a modular 800-volt drive and consists of silicon carbide power electronics, the electric motor and a reduction gearbox. Despite its extremely compact design and light weight, the EVbeat does not skimp on performance: the concept vehicle has a maximum torque of 5,200 Newton metres available on the rear axle – and this with a uniquely high torque density for road-legal passenger cars of 70 Newton metres per kilogram. The continuous and peak power of the electric motor is 206 and 275 kilowatts, respectively – ZF thus achieves continuous power of around 75 per cent of the peak power.

With a total weight of 74kg, the EVSys800, normalised to the same output as the latest ZF 800-volt series drive, is about 40kg or one-third lighter .

In terms of dimensions, the drive saves 50 millimetres in width thanks to the compact reduction gearbox and the ZF-patented ‘Braided Winding’ technology of the electric motor, thus enabling space-saving, coaxial installation on the drive axle.

With a total weight of 74kg, the EVSys800, normalised to the same output as the latest ZF 800-volt series drive, is about 40kg or one-third lighter and thus contributes significantly to the weight savings of the concept vehicle.

Essential for this is the electric motor with a new cooling concept and a new winding technology. For cooling, ZF allows oil to flow directly around the copper rods – exactly at the point where most heat is generated during operation. Such highly efficient cooling significantly increases performance with the same weight and installation space.

Braided Winding tech

The ‘Braided Winding’ technology developed and patented by ZF, is a further development of the so-called wave winding and enables a total of 10 percent less installation space. The winding head alone is up to 50 percent smaller than with conventional approaches. This saves around 10 percent in copper.

The inverter of the electric drive has been fundamentally redesigned. All essential components have been fundamentally revised. Significant improvements were achieved in each of the areas of electromagnetic compatibility, power modules and capacitors in terms of installation space, weight and sustainability.

Patented braided winding tech enables a total of 10% less installation space.

A new, coaxial reduction gearbox transmits the drive forces of the electric motor via two planetary gear sets. They not only generate the desired final drive ratio, but also perform the fully integrated differential function. Compared with conventional offset concepts, in which the input and output shafts are not on the same axis, the coaxial solution reduces weight and installation space requirements without compromising on efficiency, noise and vibration. In combination with ‘Braided Winding’ technology, this drive can be made significantly shorter, allowing installation in almost any vehicle installation space.

“With this system, we can perfectly meet the main requirements of our customers – namely efficiency, performance and costs,” said Dr Otmar Scharrer. The first technologies of the new ZF driveline will be available on the market from 2026.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

29 Jun 2023

29 Jun 2023

6533 Views

6533 Views

Ajit Dalvi

Ajit Dalvi