ZF’s Innovation Forklift premieres at 2018 Hannover Messe

The new automated forklift truck showcased at Hannover Messe has the ability to see, think and act.

ZF has introduced a highly automated, electrified and fully networked forklift truck at the Hannover Messe. It claims to be the first such forklift with an inbuilt AI.

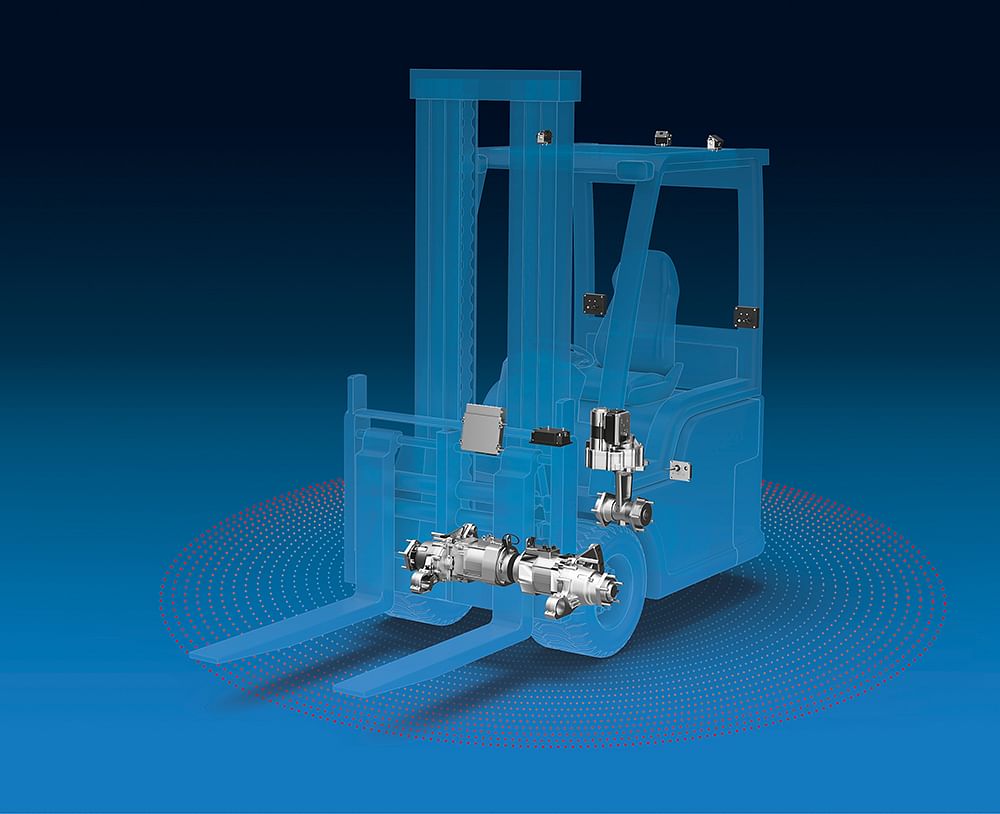

With the ZF Innovation Forklift, German-based ZF Friedrichshafen AG claims that it is the first ever materials handling vehicle that can see, think and act. It is a fully networked electric forklift truck with highly automated driving functions equipped with camera and radar systems that enables it to see its surrounding environment. The data that these systems generate are analyzed by the ZF ProAI central computer, which is based on an artificial intelligence software that has already been proven in other innovative prototype vehicles modelled on passenger cars and tractors. Intelligent actuating elements – such as the ZF electric rear axle steering for forklift trucks – and the electric ZF single-wheel drive carry out the control unit's given commands.

ZF Innovation Forklift capable of evasive manoeuvres – Highly automated driving functions ensures greater workplace safety. The ZF Innovation Forklift independently drives around obstacles and comes to a stop if people are in its path.

ZF CEO Wolf-Henning Scheider says, “The highly automated ZF Innovation Forklift is the result of bundled know-how to create a unique and comprehensive solution that essentially embraces the main requirements of the industry: reducing costs and making materials handling processes far more efficient.”

According to ZF, Innovation Forklift bundles digitalization, automation, electrification and networking. This highly automated forklift truck completes work orders by independently going to the storage location, picking up the goods and delivering them to the customer. Equipped with an extremely powerful electric drive and featuring a lifting capacity of up to 3.5 tons, the ZF Innovation Truck is coming well within the range of the diesel-operated forklift trucks broadly used outdoors; and it generates zero emissions. ZF supplies the purely electric drive as a system solution and has streamlined the forklift truck’s energy management so that it can hold a battery charge for at least one shift. This means that operators do not have to have as many replacement batteries on hand and can, therefore, reduce costs considerably. Intelligent object and pedestrian detection is a major safety bonus when the vehicle is in operation.

ZF Innovation Forklift system presentation – Fast industrial technology innovations thanks to technology transfer.

The ZF Innovation Forklift sensors record people or stationary objects such as pallet cages or simply pallets. The data interpreted in the ZF ProAI central control unit results in a corresponding command that tells the vehicle to either stop or drive around the obstacle. Deep learning algorithms help to anticipate a variety of potential scenarios in high speed and then triggers adequate reactions. In other words, artificial intelligence can help to prevent work accidents and injury to people or material damage. The vehicle can also prioritize orders itself and thus make decisions regarding the optimal sequence and route. The vehicle can operate in a digitalized production network and therefore, communicate both with the materials management system, infrastructure and other vehicles. The cloud-based, dynamic fleet management allows the data from the individual forklift trucks to be efficiently managed and analyzed. The system takes into account, for example, the current battery charge status during all driving operations and schedules the recharge time at which the forklift truck should independently head toward the charging station.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

23 Apr 2018

23 Apr 2018

5819 Views

5819 Views

Ajit Dalvi

Ajit Dalvi