Volvo to deploy blockchain tech for traceability of cobalt in li-ion batteries

The traceability of raw materials used in lithium-ion batteries, such as cobalt, remains one of the key sustainability challenges for car makers. Volvo is partnering battery suppliers CATL and LG Chem in this eco-friendly exercise.

Volvo Cars has reached an agreement with its two global battery suppliers, CATL of China and LG Chem of South Korea, and leading global blockchain technology firms to implement traceability of cobalt, starting this year.

With this, Volvo Cars will become the first car manufacturer to implement global traceability of cobalt used in its batteries. It will be using blockchain technology to trace the raw material used for the lithium-ion batteries in its electric cars. Blockchain tech helps establish a data sharing network and boosts the transparency of the raw material supply chain. As a result, information about the core material’s origin cannot be changed undetected.

The traceability of raw materials used in lithium-ion batteries, such as cobalt, remains one of the key sustainability challenges for car makers. Volvo Cars says it is keen on ensuring that customers can drive electrified Volvos knowing the battery material is sourced responsibly. Martina Buchhauser, Head of Procurement at Volvo Cars said, “We have always been committed to an ethical supply chain for our raw materials. With blockchain technology, we can take the next step towards ensuring full traceability of our supply chain and minimising any related risks, in close collaboration with our suppliers.”

Technology firms Circulor and Oracle operate the blockchain technology across CATL’s supply chain following a successful pilot earlier this year, while the Responsible Sourcing Blockchain Network (RSBN), together with responsible sourcing specialists RCS Global and IBM, is rolling out the technology in LG Chem’s supply chain.

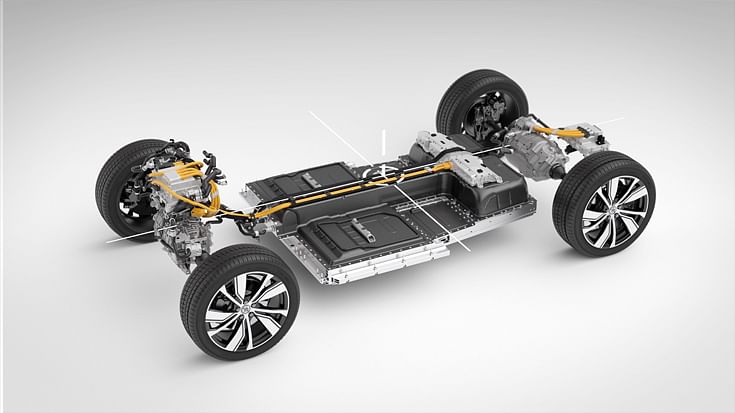

Volvo XC40 recharge battery package.

Volvo Cars launched the XC40 Recharge, the first of an upcoming family of fully electric cars under the Recharge banner last month. By 2025, it expects half of its global sales from fully electric cars, with the rest from hybrids. It also targets radical reduction of carbon emissions by 40 percent per vehicle by 2025.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

06 Nov 2019

06 Nov 2019

5271 Views

5271 Views

Ajit Dalvi

Ajit Dalvi