New ultra-capacitor tech could drastically boost battery EV range

Ultra-capacitor is claimed to store and discharge electrical energy much more quickly than lithium ion cell.

A fast-acting carbon ‘ultra-capacitor’ that could take 30 percent off the weight of a lithium-ion EV battery pack is under development in France.

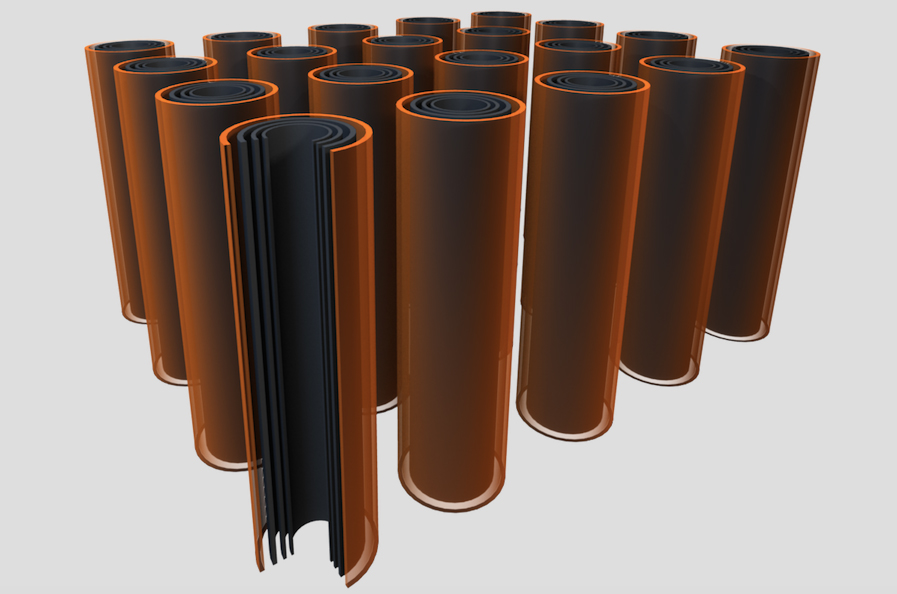

The ultra-capacitor, which is built using carbon and graphene nano-technology, is claimed to store and discharge electrical energy much more quickly than a lithium-ion cell.

“Our advantage is the speed of charge and discharge,” said Ulrik Grape, chief executive of NAWA Technology, the company responsible for the device. “Our carbon battery can pick up energy from regenerative braking and supply it back to the motor very quickly.”

Ultra-capacitors offer very fast energy transfer but don’t have a large storage capacity. According to NAWA, the ultra-capacitor could be integrated into a lithium ion battery to provide instant power for improved performance, while reducing the number of the charge and discharge cycles the main battery performs, thus extending its life.

It is claimed that a simulation on the battery pack of a Formula E racing car modified to include a NAWA ultra-capacitor demonstrated the same performance and range but weighed 30% less.

It is claimed that a simulation on the battery pack of a Formula E racing car modified to include a NAWA ultra-capacitor demonstrated the same performance and range but weighed 30% less.

The design of the ultra-capacitor is said to be unique. It offers a higher stored energy density than rivals by combining an electrolyte with microscopic coatings on the billions of carbon nanotubes inside the stack.

NAWA is looking at developing the design for production. It said it is targeting premium European car firms first with the “aim of full production in 2022”, although it expects to start making capacitors for power tools and material handling firms next year.

One option is to mould the nano-tubes into body panels. Last year, Lamborghini showed the Terzo Millennio concept, built in conjunction with the Massachusetts Institute of Technology, that had bodywork made of carbon nano-tube ultra-capacitors.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

09 May 2018

09 May 2018

5929 Views

5929 Views

Ajit Dalvi

Ajit Dalvi