TRW’s new-gen seatbelt retractor offers weight and packaging advantages

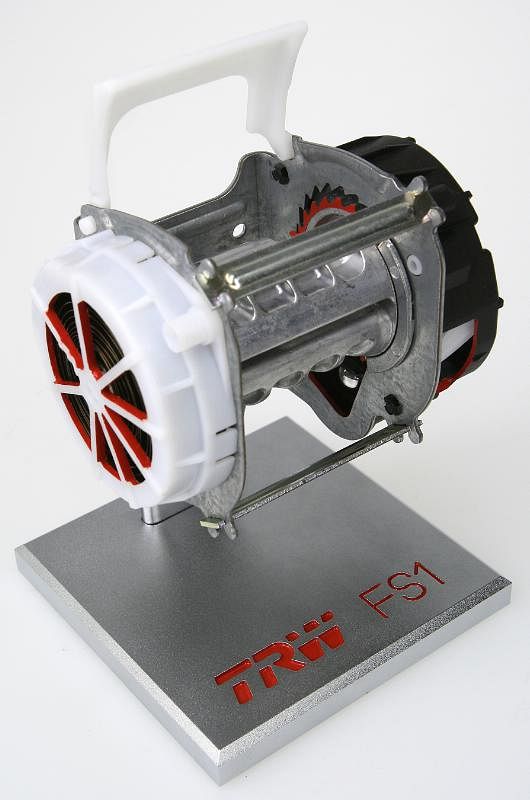

TRW Automotive is to launch its next-generation seatbelt retractor – the Floating Spool 1 (FS1) – which offers reduced weight and smaller dimensions when compared with previous systems.

TRW Automotive is to launch its next-generation seatbelt retractor – the Floating Spool 1 (FS1) – which offers reduced weight and smaller dimensions when compared with previous systems. The global FS1 technology is starting production with several vehicle manufacturers in Asia, Europe, North America and South America during the second quarter of 2014.

In a crash scenario, most seatbelt retractors use a lock pawl to hold the webbing in place. Instead, the new FS1 design with fewer components uses the forward movement of the occupant to apply force to the webbing, which then moves the spool, locking the retractor. It offers a simpler, standardised component design that can be easily adapted to local market requirements at a highly competitive cost, and can be produced using fully automated or semi-automated manufacturing processes.

Aziz Canatar, global engineering director, TRW Seat Belt Systems, said: "Our new FS1 technology weighs approximately 15 percent less than the previous generation, making it a more environmentally friendly product that can help automobile manufacturers meet emissions and fuel economy targets. In addition, the smaller retractor offers significant packaging advantages and greater installation options."

The new retractor technology is suitable for front and rear seat applications using buckles and/or anchor pretensioners. The FS1 is available as a standard retractor without load limiter, but also with a constant load limiter using a standard torsion bar.

Both standard and reverse payout versions are available with the FS1. The sensor locking mechanism, with fewer moving parts, gives it excellent NVH characteristics. Optional functions include a child seat restraint feature, sensor blockout for folding seats and a noise dampening system.

Canatar added: "The design of the new FS1 offers many advantages related to weight, size and packaging flexibility. Standardized components and assembly options make it a truly cost-competitive, global technology. TRW believes FS1 is the retractor of choice to meet global market needs both now and in the future."

Photograph: TRW’s global FS1 technology is starting production with several vehicle manufacturers in Asia, Europe, North America and South America during Q2, 2014.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

24 Jun 2014

24 Jun 2014

6769 Views

6769 Views

Ajit Dalvi

Ajit Dalvi