Toyota prepares for new model in China, plans new production line in Tianjin

The new production line with an annual capacity of roughly 100,000 units will see an investment of approximately 59 billion yen (Rs 3,068 crore).

In line with its plan to enhance competiveness and flexibility at its manufacturing plants worldwide, Toyota is to reorganise its operations in Tianjin, China by improving and automating some processes on existing production lines, while also establishing a new line. This reorganisation, according to Toyota, is for plants that are competitive, rather than plants that simply aim to maximise production.

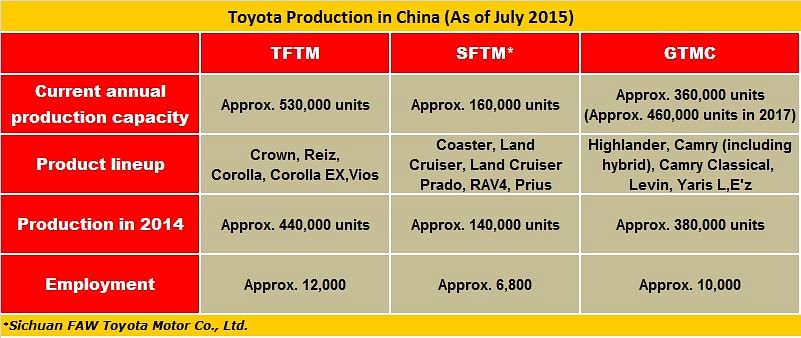

The new production line with an annual capacity of roughly 100,000 units is planned to begin production of a new vehicle model by mid-2018. Approximately 59 billion yen (Rs 3,068 crore) will be invested in the line to be located in the Tianjin Economic-Technological Development Area (TEDA) and operated by Tianjin FAW Toyota Motor Co., Ltd. (TFTM), a joint venture established with China FAW Group Corporation (FAW).

The new line will take flexibility to a new level, allowing lengthening or shortening according to changes in vehicle model or volume. In addition, the implementation of the Toyota New Global Architecture (TNGA) will help boost TFTM's overall productivity.

Despite the addition of the new line, TFTM's overall production capacity is projected to remain at roughly current levels, since an aging TFTM line will stop vehicle production by the end of 2017.

Since the 1970s, Toyota and FAW have maintained a strong relationship based on active exchange of information, establishing a long-term strategic relationship in 2002. Both partners will continue to make mutual efforts towards further development of the automotive industry in China.

Toyota also announced in April that it would be restructuring its existing lines and building an additional production line by the end of 2017 at GAC Toyota Motor Co (GTMC) in Guangzhou, China.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

05 Aug 2015

05 Aug 2015

5466 Views

5466 Views

Ajit Dalvi

Ajit Dalvi