Toshiba releases Bluetooth version 5 compliant chip for automotive applications

Said to be AEC-Q100 compliant, the chip contains both analog RF and baseband digital parts along with +8dBm for long distance communication.

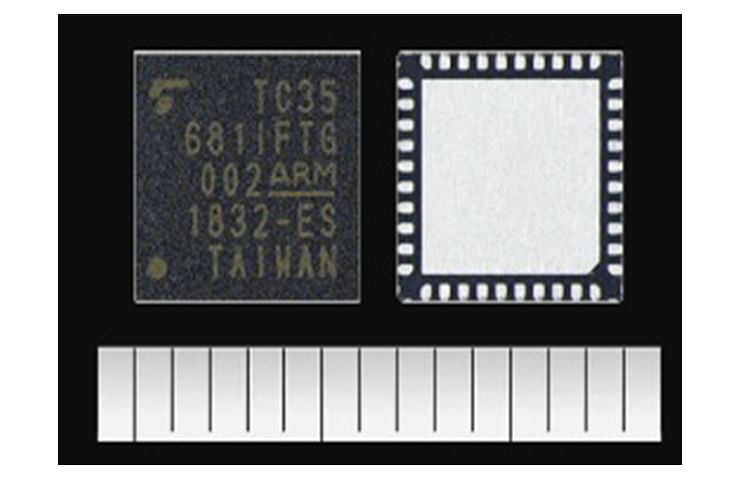

Toshiba Electronic Devices and Storage Corporation has added ‘TC35681IFTG’, a new IC for automotive applications, to its line-up of ICs compliant with Bluetooth low energy (LE) core. It belongs to the version 5.0 (v5.0) specification. The new device is meant for use in demanding automotive environments, as it delivers a wide operating temperature range, high RF transmission power and high RF reception sensitivity (a link budget of 113dB @125kbps at long range transmission). The mixed-signal TC35681IFTG contains both analog RF and baseband digital parts to provide a complete solution on a single chip.

In addition to the basic functions of Host Controller Interface (HCI) profile and GATT profile functions, TC35681IFTG adds the new functions defined by Bluetooth core specification 5.0, including 2 Mbps throughput, long range and advertising extension functions, stored in internal mask ROM. It also integrates a high gain power amplifier and realises +8dBm for long distance communication.

When used in conjunction with an external non-volatile memory, the new IC becomes a fully-fledged application processor that temporarily loads applications and stores in its internal RAM. It can also be combined with an external host processor.

According to Toshiba, the integration of 18 General Purpose IO (GPIO) lines and multiple communications options including SPI, I2C and a 921.6kbps two-channel UART, gives TC35681IFTG the ability to form part of sophisticated systems. The GPIO lines offer access to a range of on-chip features including a wake-up interface, four-channel PWM interface and 5-channel AD converter. An on-chip DC-DC converter or LDO circuits adjust the external voltage supply to the required values on the chip.

It is said to be compliant with AEC-Q100 (a set of qualification test sequences for integrated circuits developed by the Automotive Electronics Council (AEC)). The low energy IC is primarily intended to be used in automotive applications. The wettable flank package simplifies automatic visual inspection required to maintain high levels of soldering quality enabling it to withstand the vibration experienced in automotive applications.

Current applications include remote keyless entry, on-board diagnostics to collect sensor data, tire pressure monitoring systems, and other contributors to improved vehicle comfort and safety.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

30 Oct 2018

30 Oct 2018

3080 Views

3080 Views

Ajit Dalvi

Ajit Dalvi