Supply chain disruptions driving shift from ‘just-in-time’ to ‘just-in-case’: ABB Robotics study

Supply chain disruption and rising material costs are causing the global automotive industry to re-evaluate lean manufacturing principles and a shift to greater stock-holding – a move away from the just-in-time approach

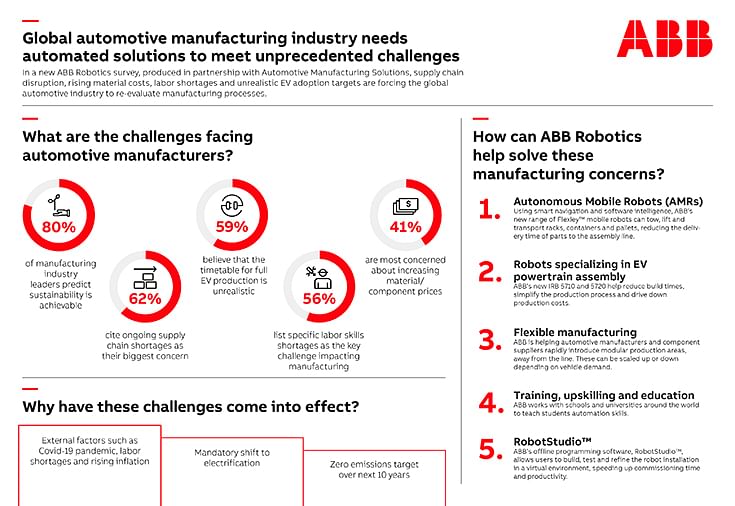

Supply chain disruption and rising material costs are causing the global automotive industry to re-evaluate lean manufacturing principles, reveals a new survey commissioned by ABB Robotics. Shifting from ‘just-in-time’ to ‘just in case’ strategies, manufacturers are holding more stock to protect against unplanned disruptions.

The study’s finding reveals that supply chain concerns are creating a shift to greater stock-holding – a move away from the just-in-time approach. Also, rising costs and the desire to operate more sustainably are sharpening the focus on operational and energy efficiency gains through automation.

Produced in partnership with Automotive Manufacturing Solutions, the survey was completed by a mix of global industry experts from vehicle manufacturers, suppliers and engineering. Nearly two-thirds (62%) of respondents cited ongoing supply chain concerns when asked to select their top three challenges to automotive manufacturing, while 41% cited the impacts of material and component price increases and 31% pointed to growing labour costs and shortages. The survey also revealed how manufacturers were turning to increased stock-holding and bulk material purchasing to limit their exposure to disruption elsewhere in the supply chain, while working with a wider network of suppliers to ensure sufficient availability of parts.

“This seismic shift in manufacturing logistics requires smart, effective solutions,” said Joerg Reger, Managing Director of ABB Robotics Automotive Business Line. “ABB is addressing these challenges directly with more efficient and flexible solutions, such as our range of AMRs (autonomous mobile robots) which can greatly improve the speed of delivery of critical parts to the assembly line.”

The survey highlighted how the rising cost of raw materials (62%) had already overtaken energy costs (59%) as the industry’s chief concern. Energy efficiency continues to be important, while an identical number of respondents (17%) felt that tighter cost management was crucial to the industry’s response. After launching in 2022, innovative solutions like ABB PixelPaint are helping reduce waste and increase efficiency in automotive painting applications, enabling manufacturers to better manage costs while operating more sustainably.

The ABB survey includes close to 600 global industry experts, from vehicle manufacturers, and supplies at all levels of management, engineering and other key professionals throughout the automotive world.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

22 Mar 2023

22 Mar 2023

6246 Views

6246 Views

Ajit Dalvi

Ajit Dalvi