New made-in-Europe Nissan Qashqai goes high on lightweight aluminium

With the hood, doors and front fenders stamped from aluminium alloy, the body of the all-new Qashqai is 60kg lighter.

The all-new Qashqai will be Nissan’s first model built in Europe using a significant number of lightweight aluminium panels.

The hood, doors and front fenders are stamped from aluminium alloy, which makes the body of the all-new Qashqai 60kg lighter. This improves efficiency and thereby contributes to reduced emissions. In addition, it helps accommodate more technology, including the all-new vehicle’s electrified powertrain.

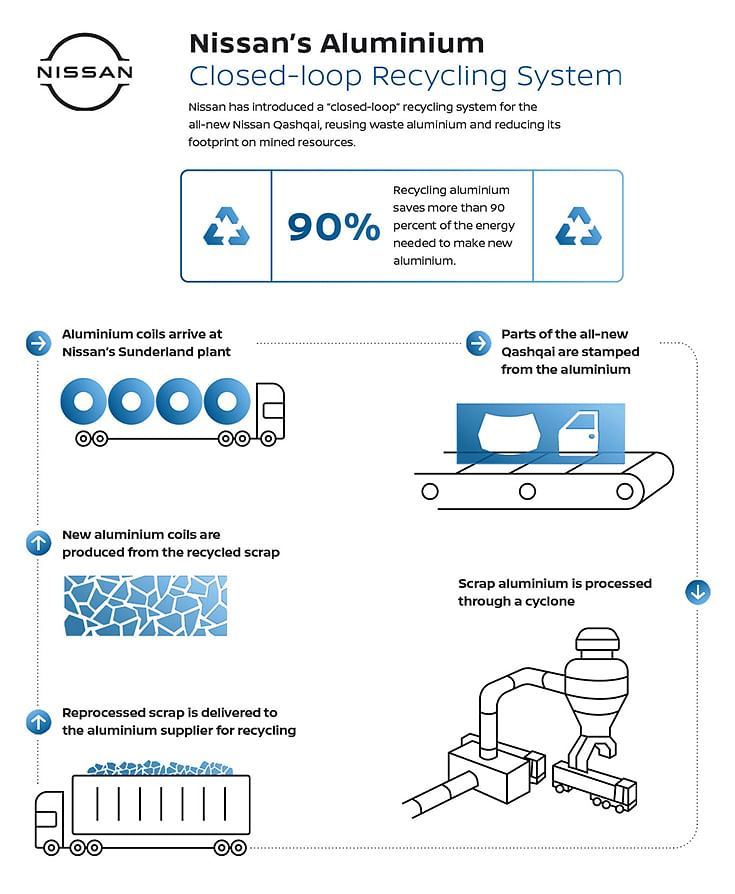

Aluminium production at Nissan’s Sunderland plant includes the second extra large press line that was launched last year and the cyclone – a recycling facility that blasts out scrap metal at 150km an hour and can handle more than seven tons of metal an hour, ensuring less waste and a greener production process.

As hoods and doors are stamped into shape, scrap material is shredded and extracted, keeping aluminium grades separate. The separation ensures that Nissan can return high-quality scrap to suppliers for them to turn into aluminium alloy sheets.

This ‘closed-loop’ recycling system reduces waste and CO2 emissions. This contributes to the goal Nissan has set itself of achieving carbon neutrality across the company’s operations and the lifecycle of its products by 2050.

Recycling scrap aluminium saves more than 90% of the energy needed to create a comparable amount from raw materials.

Vice President Manufacturing Alan Johnson of Nissan Motor Manufacturing UK, said: “We continue to look for ways to make both our vehicles and our manufacturing process more sustainable. The use of lightweight aluminium in the new Qashqai is a great example.”

The new Qashqai follows the new Rogue sold in North America as the second global model for Nissan to feature aluminium parts produced with the closed-loop recycling process. Nissan is considering expanding the application of this process to future models and other factories.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

28 May 2021

28 May 2021

4323 Views

4323 Views

Ajit Dalvi

Ajit Dalvi