Mercedes-Benz Cars to produce electric powertrain at Unterturkheim plant

The Unterturkheim plant of Mercedes-Benz Cars will produce electric vehicles of the EQ product and technology brand.

The management and works council of the Mercedes-Benz Unterturkheim plant in Germany have reached an agreement to manufacture and assemble parts of the electric powertrain (eATS). The company and the employees have agreed on defined production ranges of the eATS and have come up with a set of measures to increase competitiveness and profitability. Unterturkheim plant will produce electric vehicles of the EQ product and technology brand.

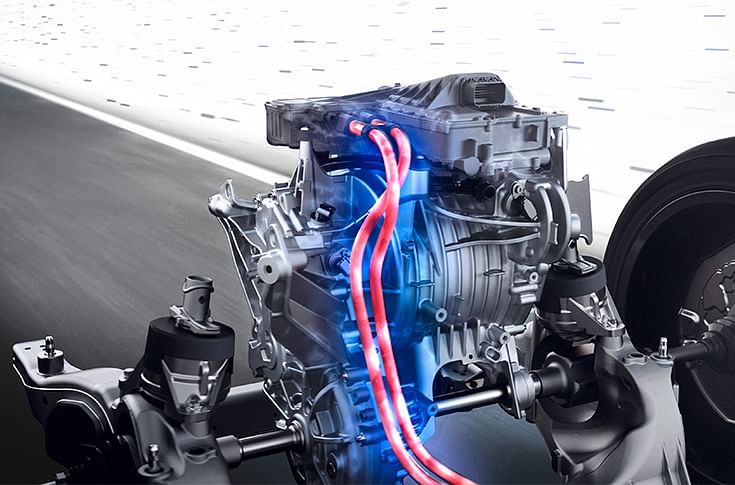

The eATS is the drive unit of electric vehicles. The eATS consists essentially of the three subsystems: an electric motor, its power electronics and the transmission part for power transmission. The power-transmission wheelset and other components such as the control system will be manufactured in Unterturkheim. The assembly of these components into a complete system will also take place at the Mercedes-Benz Unterturkheim plant.

The company and the works council agree that the Mercedes-Benz Unterturkheim site has the necessary conditions to implement the production of parts of the electric powertrain and its assembly economically and competitively. In addition, the objective of the agreed measures is on one hand to react even more flexibly to changes of the market and, on the other hand, to further expand the Untertürkheim plant as a competitive location for electromobility. Adjustments in the organization of operations are a key lever for achieving these preconditions. They include, for example, a platform for making the use of staff more flexible, which employees will be able to apply for.

Michael Haberle, chairman of the Works Council of the Mercedes-Benz Unterturkheim plant said, “With the eATS, we have taken another important step towards the future. In combination with the combustion engines, the battery factory and fuel cells, we are broadly positioned and have anchored all drive technologies in Untertürkheim so that we can continue to be Daimler’s lead plant and competence center for drive technologies in the future.”

He further explained, “With the eATS, we have taken another important step towards the future. In combination with combustion engines, the battery factory and fuel cells, we are broadly positioned and have anchored all drive technologies in Unterturkheim so that we can continue to be Daimler’s lead plant and competence center for drive technologies in the future.”

Frank Deib, head of production Powertrain Mercedes-Benz Cars and responsible for the Mercedes-Benz plant in Unterturkheim said, “I am delighted that after intensive discussions with the works council, we have been able to agree on framework for the future. Producing the eATS at the Mercedes-Benz plant in Unterturkheim is the consistent continuation of our transformation in the Neckar Valley.”

Since the beginning of 2019, the Unterturkheim plant has also been responsible for the battery ramp-up factory, which forms the bridge between development and series production. A battery factory is being built at the Unterturkheim site in Hedelfingen. A second battery factory is being built at the Bruhl facility near Esslingen. Mercedes-Benz Cars will start carbon neutral production here on floor space of 12,000 square meters early in the next decade. Mercedes-Benz has confirmed that all employees who will be working on battery assembly in the future, will be trained in high-voltage technology. In addition, they will receive training in the ramp-up factory for batteries at the Unterturkheim site.

Mercedes-Benz claims that the Unterturkheim plant has a 115-year tradition, is the largest facility in the worldwide powertrain production network, and the headquarters of the Daimler Group are located here. With more than 19,000 employees, the plant produces engines, axles, transmissions and components.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

14 Dec 2019

14 Dec 2019

10250 Views

10250 Views

Ajit Dalvi

Ajit Dalvi