Mercedes-Benz opens Europe's first battery recycling plant

Mercedes-Benz becomes the first car manufacturer worldwide to close the battery recycling loop with its own in-house facility in Kuppenheim, Germany; expected recovery rate of more than 96% and net CO2-neutral operation; plant to generate enough recycled materials to produce more than 50,000 new battery modules per year

Mercedes-Benz has opened Europe's first battery recycling plant with an integrated mechanical-hydrometallurgical process making it the first car manufacturer worldwide to close the battery recycling loop with its own in-house facility. The recycling plant in Kuppenheim, southern Germany, creates a genuine circular economy.

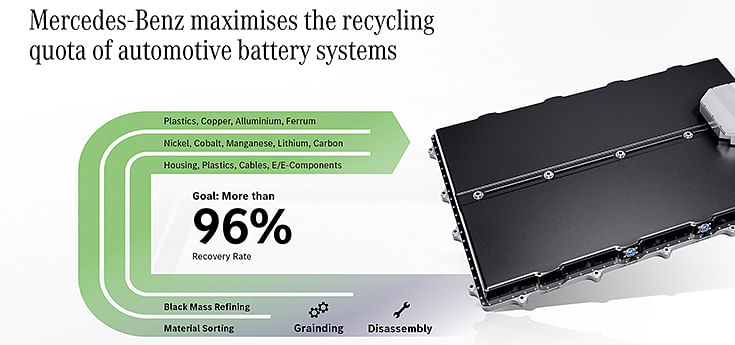

Unlike existing established processes, the expected recovery rate of the mechanical-hydrometallurgical recycling plant is more than 96 percent. Valuable and scarce raw materials such as lithium, nickel and cobalt can be recovered – in a way which is suitable for use in new batteries for future all-electric Mercedes-Benz vehicles.

The company has invested tens of millions of euros in the construction of the new battery recycling plant and thus in the value creation in Germany. Federal Chancellor Olaf Scholz and Baden-Württemberg's Environment Minister Thekla Walker visited the plant for the opening ceremony in Kuppenheim, Baden.

“Mercedes-Benz has set itself the goal of building the most desirable cars in a sustainable way. As a pioneer in automotive engineering, Europe's first integrated mechanical-hydrometallurgical battery recycling factory marks a key milestone towards enhancing raw-materials sustainability. Together with our partners from industry and science, we are sending a strong signal of innovative strength for sustainable electric mobility and value creation in Germany and Europe," said Ola Kallenius, Chairman of the Board of Management of Mercedes-Benz Group AG

“The future of the automobile is electric, and batteries are an essential component of this. To produce batteries in a resource-conserving and sustainable way, recycling is also key. The circular economy is a growth engine and, at the same time, an essential building block for achieving our climate targets! I congratulate Mercedes-Benz for its courage and foresight shown by this investment in Kuppenheim. Germany remains a cutting-edge market for new and innovative technologies,” commented Olaf Scholz, Federal Chancellor of the Federal Republic of Germany

Mercedes-Benz’s technology partner for the battery recycling factory is Primobius, a joint venture between German plant and mechanical engineering company SMS group and Australian process technology developer Neometals. The plant is receiving funding from the German Federal Ministry for Economic Affairs and Climate Action as part of a scientific research project with three German universities. The project looks at the entire process chain for recycling, including logistics and reintegration concepts. The partners are thus making an important contribution to future scaling of the battery recycling industry in Germany.

Unlike existing established processes, the expected recovery rate of the mechanical-hydrometallurgical recycling plant is more than 96 percent.

Unlike existing established processes, the expected recovery rate of the mechanical-hydrometallurgical recycling plant is more than 96 percent.

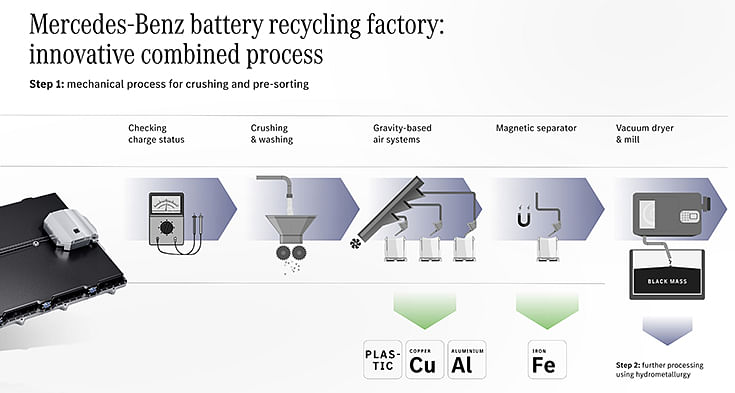

Integrated mechanical-hydrometallurgical recycling concept

For the first time in Europe, the Mercedes-Benz battery recycling plant covers all steps from shredding battery modules to drying and processing active battery materials. The mechanical process sorts and separates plastics, copper, aluminium and iron in a complex, multi-stage process. The downstream hydrometallurgical process is dedicated to the so-called black mass. These are the active materials that make up the electrodes of the battery cells. The valuable metals cobalt, nickel and lithium are extracted individually in a multi-stage chemical process. These recyclates are of battery quality and therefore suitable for use in the production of new battery cells.

Unlike the pyrometallurgy established in Europe today, the hydrometallurgical process is less-intensive in terms of energy consumption and material waste. Its low process temperatures of up to 80 degrees Celsius mean it consumes less energy. In addition, like all Mercedes-Benz production plants, the recycling plant operates in a net carbon-neutral manner. It is supplied with 100 percent green electricity. The roof area of the 6800 square-metre building is equipped with a photovoltaic system with a peak output of more than 350 kilowatts.

The Mercedes-Benz battery recycling plant in Kuppenheim has an annual capacity of 2,500 tonnes. The recovered materials feed into the production of more than 50,000 battery modules for new all-electric Mercedes-Benz models. The knowledge gained could help scale up production volumes in the medium to long term.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

22 Oct 2024

22 Oct 2024

9697 Views

9697 Views

Ajit Dalvi

Ajit Dalvi