Idemitsu and Toyota collaborate to manufacture solid-state batteries for EVs

Idemitsu Kosan Co and Toyota join forces to develop mass production technology of solid electrolytes, improve productivity and establish a supply chain; target mass production of all-solid-state batteries for BEVs in 2027-28.

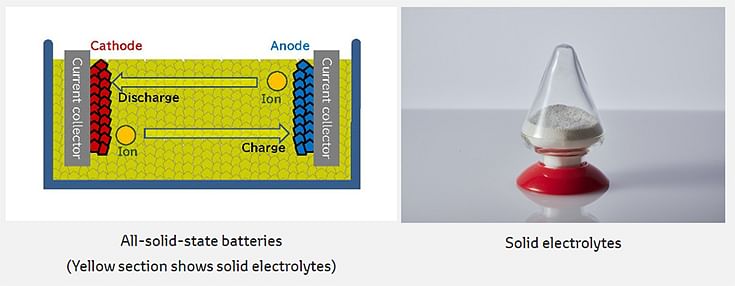

Idemitsu Kosan Co (Idemitsu) and Toyota Motor Corporation have announced today that they have entered into an agreement to work together in developing mass production technology of solid electrolytes, improving productivity and establishment a supply chain, to achieve the mass production of all-solid-state batteries for battery electric vehicles (BEVs).

Through this collaboration, the two companies, which lead the world* in the fields including material development relating to all-solid-state batteries, seek to ensure the successful commercialization of all-solid-state batteries in 2027-28, followed by full-scale mass production.

While Idemitsu has been working on research and development on elemental technologies for all-solid-state batteries since 2001, Toyota started in 2006.

This collaboration focuses on sulfide solid electrolytes, which are seen as a promising material to achieve high capacity and output for BEVs. Sulfide solid electrolytes are characterized by softness and adhesiveness to other materials, which is suitable for battery mass production.

To prepare for full-scale mass production, both companies have established a task force consisting of dozens of members and will proceed the collaboration as follows:

DETAILS OF THE COLLABORATION

Phase 1: Development of sulfide solid electrolytes and preparation for a large pilot facility

Through feedback and development support from each other on each company's technical area, both Idemitsu and Toyota will work together on creating better sulfide solid electrolytes with attention to quality, cost, and lead times, which both companies believe will realize mass-production demonstration of sulfide solid electrolytes using an Idemitsu pilot facility.

Phase 2: Mass production using a large pilot facility

Through construction and startup of a large pilot facility, Idemitsu will promote sulfide solid electrolyte manufacture, and then will obtain mass production technology.

Toyota will promote development of both all-solid-state batteries which sulfide solid electrolytes are used and BEV development in which the batteries are incorporated, and then will ensure market launch of BEVs with all-solid-state batteries in 2027-28.

Phase 3: Study of future full-scale mass production

Based on the results of Phase 2, both companies will study of future full-scale mass production and commercialization.

Idemitsu has also been developing production technologies of lithium sulfide which is an intermediate material for solid electrolytes, using by-products which are generated in the course of petroleum refining. And through such development, it has been working on development of mass production technology on sulfide solid electrolytes, aiming to establish a stable supply system. Further, the company is steadily increasing the capacity of its small pilot facility ― announced in June 2023―and is proceeding construction plan of a large pilot facility ― announced in April 2022 ―, which will contribute to commercialization of all-solid-state batteries in 2027-28.

Through combination of both companies' material development technologies, Idemitsu's material manufacture technologies and Toyota's battery processing and assembly technologies which is obtained through BEV development, both companies will aim to realize mass production of both solid electrolytes and all-solid-state batteries suitable for global widespread use. Both companies, working together across industries, will contribute to global carbon neutrality, and will lead the future with technologies created in Japan.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

12 Oct 2023

12 Oct 2023

6308 Views

6308 Views

Ajit Dalvi

Ajit Dalvi