Hyundai Motor Group increases annual EV sales target by 2030 to 2 million units

Accelerated EV strategy improves upon previous 1.87 million units target by 7%; second-gen IMA EV platform will replace Electric-Global Modular Platform (E-GMP) and help spawn 13 all-new EVs from Hyundai, Kia and Genesis through 2030.

Hyundai Motor Company unveiled its mid- to long-term business strategies and financial plans at the ‘2023 CEO Investor Day’ in Seoul held on June 20. With the aim of actively leveraging its knowledge and heritage of innovation from internal combustion engine (ICE) vehicles, the Korean automaker is committed to a successful transition to the electrification era.

The company will implement this strategy and accelerate its transition toward becoming a smart mobility solution provider by securing a large-scale investment of KRW 109.4 trillion over the next 10 years. Furthermore, in order to secure leadership in the future mobility industry, it has decided to focus on future businesses, such as autonomous driving, hydrogen, robotics and advanced air mobility (AAM).

In particular, the company has decided to initiate its ‘Hyundai Motor Way’ strategy by securing KRW 109.4 trillion for its next decade investment, including KRW 35.8 trillion (Rs 227,151 crore) for electrification. The company is targeting 2 million units in annual EV sales by 2030. This is a

The key parts of the strategy include introducing a next-generation modular architecture for EVs, strengthening EV production capacity, battery development capabilities and future businesses.

New second-gen EV platform to spawn 13 EVs

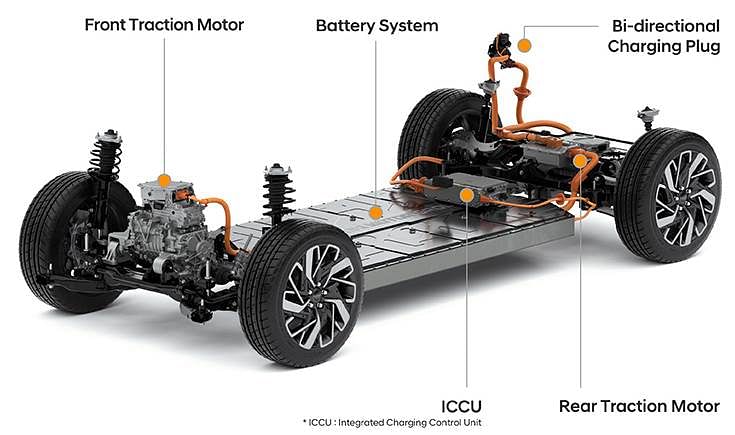

President and CEO Jaehoon Chang laid out the ‘Hyundai Motor Way’ roadmap for success in the electrification era. He explained how the company’s second-generation dedicated EV platform, under the new Integrated Modular Architecture (IMA), will replace its Electric-Global Modular Platform (E-GMP) going forward.

The next-generation platform will be used on 13 new dedicated EV models from Hyundai Motor Group’s automotive brands Hyundai, Kia and Genesis through 2030. With IMA, the company expects to standardize modules and parts between the models to further expand economies of scale and significantly reduce EV development complexity and costs.

The current E-GMP platform (above) will be replaced by the second-gen dedicated EV platform, under the new Integrated Modular Architecture.

The vehicle development system implemented by the IMA represents a significant advancement compared to the current system, enabling maximum cost reduction through economies of scale. In the existing system, auto parts can only be shared among vehicles that share the same platform. However, with the IMA development system, over 80 common modules can be utilised across different segments, irrespective of vehicle type, allowing for versatile combinations. This breakthrough allows for greater flexibility and efficiency in the development process, paving the way for significant cost savings.

In the second-generation platform, the scope of vehicle development extends beyond the mid-sized SUVs covered by the current E-GMP system. It encompasses nearly all vehicle classes, ranging from small and large SUVs to pickup trucks, along with the flagship models of the Genesis brand.

Hyundai Motor plans to apply a range of battery solutions, including next-generation NCM batteries and LFP batteries, for the second-generation platform. The company is also exploring different form factors of batteries to enhance versatility. To further extend the driving range, Hyundai Motor intends to implement cutting-edge technology that enables battery charging and discharging while driving, utilising an independent power bank. In addition, the integration of an AI-based battery management system will ensure real-time monitoring and diagnosis of battery conditions, ensuring enhanced safety by preventing thermal runaway.

In addition to these hardware improvements, the modular architectures and next-generation platform will enable software architecture compatibility in support of Hyundai Motor’s software-defined vehicle (SDV) strategy. The company aims to build an app ecosystem through the application of an open operating system and controller integration, including Level 3 and higher autonomous driving capabilities, high-performance semiconductors and over-the-air (OTA) update advancements.

EV production ramp up with new plants, existing ICE factories

In expanding production for the electrification transition, Hyundai Motor is not only building new factories dedicated to EVs but it is also promoting a rapid and efficient demand response strategy by utilizing its existing ICE plants.

The proportion of global EV production is set to increase from 8% this year to 34% in 2030. The company plans to expand production by region through a two-track approach of line conversion in ICE factories and new dedicated EV plant establishment.

Since the demand for ICE vehicles remains high, the company is currently producing EVs on mixed production lines as it is more cost efficient than building more EV-dedicated factories. By utilizing existing lines, construction time is much shorter than building new plants and can be ramped up quickly to meet EV demand.

The company is currently producing EVs in this way at its plants in the U.S., South Korea, the Czech Republic, and India, it plans to convert additional lines as market demand dictates.

In addition, the company is building dedicated EV factories in regions that are expected to grow significantly in the future and require localization. The new factories will be equipped with new ‘smart factory’ technologies to maximize the efficiency of EV production.

Hyundai’s first dedicated EV factory, the Hyundai Motor Group Metaplant America (HMGMA) in Georgia, U.S., is under construction with a targeted start-up date in the second half of 2024, with an annual production capacity of 300,000 vehicles to meet the demand for EVs in North America. Meanwhile, an EV-dedicated factory in Korea aims to start mass production in 2025, responding not only to domestic demand for EVs but also to the rapidly growing global market.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

21 Jun 2023

21 Jun 2023

4198 Views

4198 Views

Ajit Dalvi

Ajit Dalvi