Eberspaecher starts making tunnel mixers for exhaust-emission conversion in PVs, CVs

As a core element of the AdBlue treatment, tunnel mixers enable even more effective pollutant reduction for selective catalytic reduction (SCR).

Eberspaecher Exhaust Technology has commenced series production of tunnel mixers for exhaust-emission conversion in passenger cars and commercial vehicles.

As a core element of the AdBlue treatment, they enable even more effective pollutant reduction in the context of selective catalytic reduction (SCR). The mixer, for which a patent is pending, will be produced for the first time beginning in May for a leading European passenger car manufacturer. Further customer orders will follow next year.

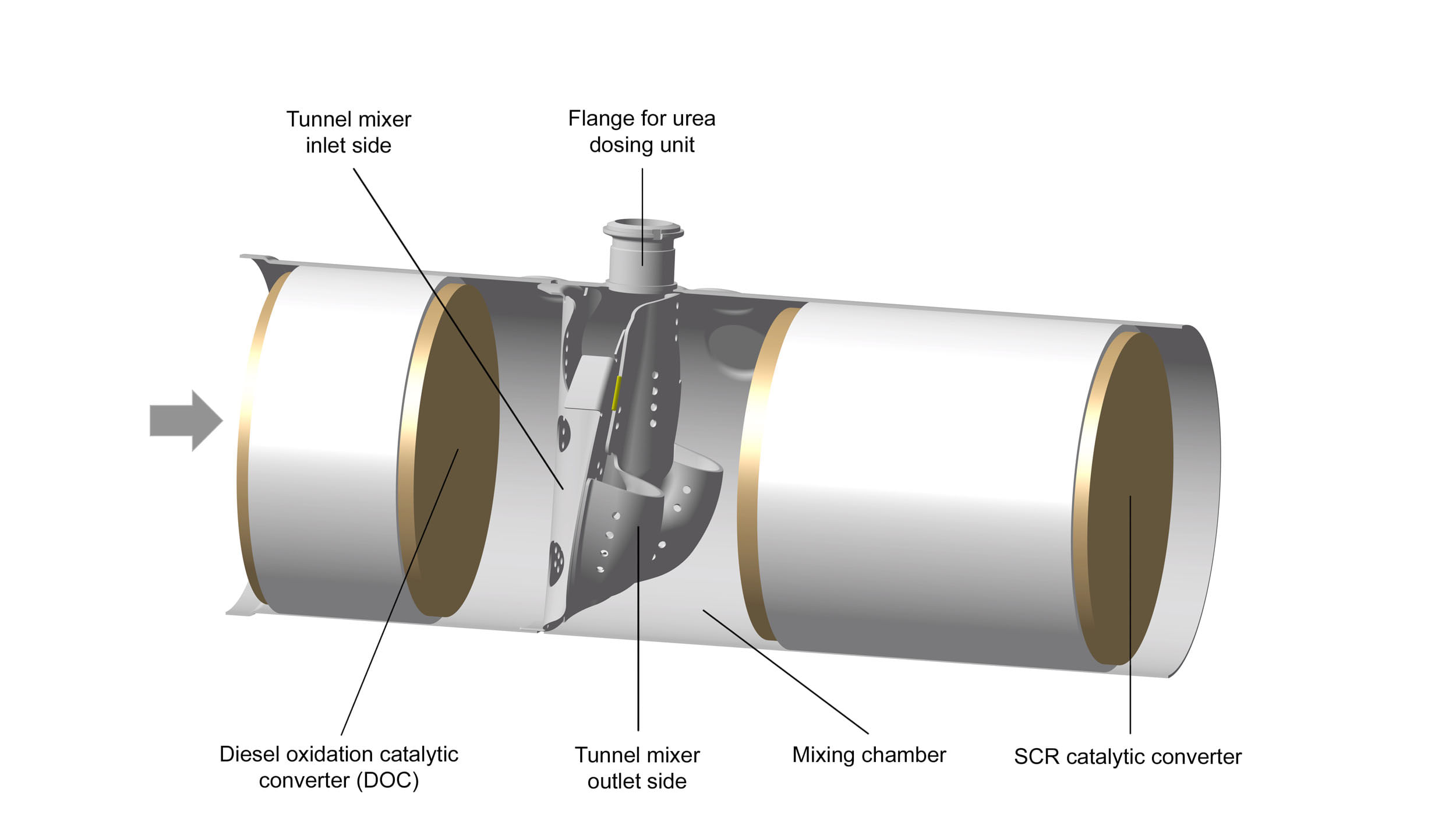

Eberspaecher tunnel mixer: optimum AdBlue treatment in SCR systems for diesel vehicles.

The introduction of the Euro 6 standard imposes strict emission limit values on passenger cars and commercial vehicles. In order to comply with these limits in technology terms, automobile manufacturers are turning to modern SCR systems for their diesel vehicles. Their purpose is to bring about chemical reduction of nitrogen oxides with the help of ammonia, which is generated in the exhaust system from the injected aqueous urea solution AdBlue.

Eberspaecher tunnel mixer: graphic representation of the installation position.

As an innovative mixing element in SCR systems, the Eberspaecher tunnel mixer enables pollutants to be minimised with maximum efficiency: Thanks to the improved design of the two deep-drawn molded parts, it ensures optimum evaporation and mixing of the aqueous urea solution with the exhaust gas. As a result, the ammonia that is released is homogeneously dispersed and reacts with the nitrogen oxides in the SCR catalytic converter to create harmless nitrogen and water. At the same time, the new mixer design relies on purposeful flow routing to minimize the occurrence of deposits. Both factors help lower AdBlue consumption and reduce what is called the NH3 slip – a strong odor nuisance caused by excess ammonia.

Compact design offers installation space benefits

Compared to the previous version, the tunnel mixer impresses with an even more robust and more compact type of design that is particularly suitable for close-coupled positioning: In the mixing section between the AdBlue injection and SCR-coated substrate, it uses the very high temperature of the exhaust gas to evaporate the aqueous urea solution – thereby triggering pollutant reduction at an earlier stage. The design can also be adapted to suit different AdBlue injectors and the different installation space requirements of all passenger car and commercial vehicle manufacturers.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

19 Mar 2018

19 Mar 2018

19781 Views

19781 Views

Ajit Dalvi

Ajit Dalvi