Dana advances development of VariGlide tech

Dana Holding Corporation, the global supplier of powertrain components, has announced new milestones in the development of VariGlide technology, a new transmission design that incorporates continuously variable planetary (CVP) technology.

Dana Holding Corporation, the global supplier of powertrain components, has announced new milestones in the development of VariGlide technology, a new transmission design that incorporates continuously variable planetary (CVP) technology. These new developments were showcased at the CeMAT 2014 exhibition, in Hanover, Germany. VariGlide is a patented, planetary traction drive that Dana plans to integrate into a variety of power paths to optimise the transmission assembly, to significantly reduce fuel consumption and maximise performance.

Developed through a strategic licensing relationship with Fallbrook Technologies Inc, this product can replace the torque converter in some transmission configurations to decouple engine speed from the vehicle's travel or working speed. Dana claims it is ideal for the rapid acceleration, deceleration, and precise positioning required by material-handling applications. It also eliminates the need for forward and reverse clutches while reducing overall engine speeds, allowing the engine to operate at its optimum efficiency level and reduce noise levels.

Initial simulations by Dana show a projected fuel savings of up to 20 percent for a standard-sized forklift truck operating in a typical pick-and-place duty cycle.

VariGlide technology will be offered as a pre-assembled module providing a standard powersplit configuration for forklift truck transmissions produced by original-equipment manufacturers (OEMs).

VariGlide technology is ideally suited to optimise the productivity of 1.5- to 3-tonne forklift trucks, which account for about 80 percent of the global material-handling equipment market today and are continuing to grow in number. In addition to forklift trucks, Dana says it is optimal for compact front-end loaders, skid steer loaders, and compact utility tractors. The CVP technology employed has been tested to a durability of 70,000 hours.

With numerous power paths and no abrupt ratio changes, VariGlide technology is said to provide an infinite number of gear ratios which Dana believes will improve shifting, driver comfort, durability, scalability, and efficiency when compared to conventional CVTs.

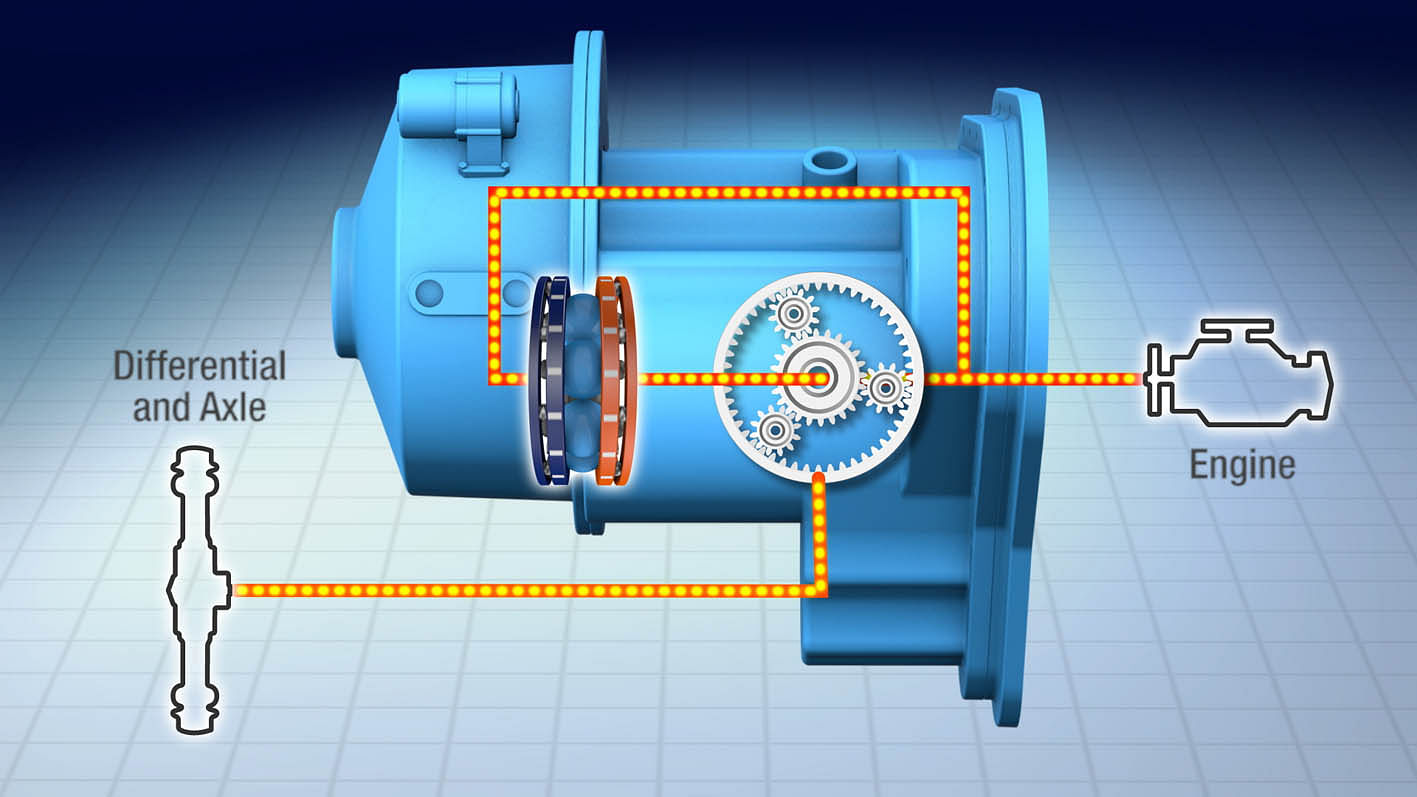

So how does VariGlide technology work? A set of spinning planets is fitted between an input disc driven by the engine and an output disc that transfers power from the variator to downstream transmission components. As power enters the input disc, the planets tilt on their axes and change ratios, depending on engine demands and controller input. To efficiently transfer torque, a thin layer of traction fluid flows between the planets. When compressed, this traction fluid becomes momentarily rigid, allowing the torque to transfer between the planets and discs without slipping.

Image: VariGlide schematic.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

28 May 2014

28 May 2014

6605 Views

6605 Views

Ajit Dalvi

Ajit Dalvi