Continental to showcase two new exhaust solutions at Bauma 2019

Continental to showcase new exhaust aftertreatment for construction machinery at Bauma 2019. Could meet future stricter NOx emissions standards.

At Bauma 2019, the world’s leading construction machinery trade fair, Continental will be presenting modular solutions designed to address future stricter nitrogen oxide (NOx) emissions standards for construction machinery. Development work will centre on strategies and products geared to maintaining an optimal exhaust system temperature across all engine operating conditions. It will be presented by the powertrain division of Continental.

At the trade fair that is going to be held from April 8 to 14, the German technology company will include solutions that include compact, low-mass, modular metallic substrates, electrically heated catalysts and fuel injection into the exhaust stream close to the catalyst.

From the middle of the next decade, the focus of emissions regulations is expected to be extended to include construction machinery, as one of the contributors to urban nitrogen oxide (NOx) emissions. The load collectives for construction machinery vary widely and are in some cases highly dynamic. Future development work to achieve efficient NOx conversion under all operating conditions will, therefore, focus on minimising the warm-up time after a cold start, and on consistently maintaining the necessary exhaust system operating temperature.

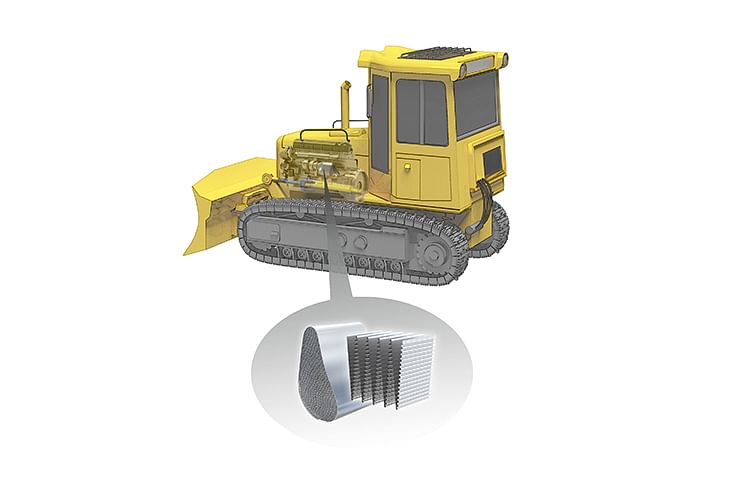

The new ‘concertina-type folding technique’ makes it possible to implement asymmetrical catalyst dimensions closely adapted to the available packaging space.

Dr Manuel Presti, program manager, powertrain components, powertrain division, Continental said, “Regulations already on the horizon for trucks will soon be followed by similar measures for non-road vehicles, including construction machinery. Here too NOx limits will be tightened, so the engine warm-up phase will be key to compliance. At Bauma, we will be demonstrating how our products can help solve the challenges facing construction machinery. Continental is already working with manufacturers on strategies to meet the stricter NOx standards of the future.”

When it comes to NOx emissions, regulations have so far paid little attention to urban construction sites. However, in just a few years’ time, much stricter nitrogen oxide limits are expected for road-going commercial vehicles such as trucks, and experience has shown that similar measures for non-road vehicles will soon follow. The cold-start phase will be particularly critical when meeting these requirements, given that the exhaust systems of construction machines such as crawler vehicles or diggers, for example, are relatively long, which means they have a high thermal mass and are subject to higher heat losses.

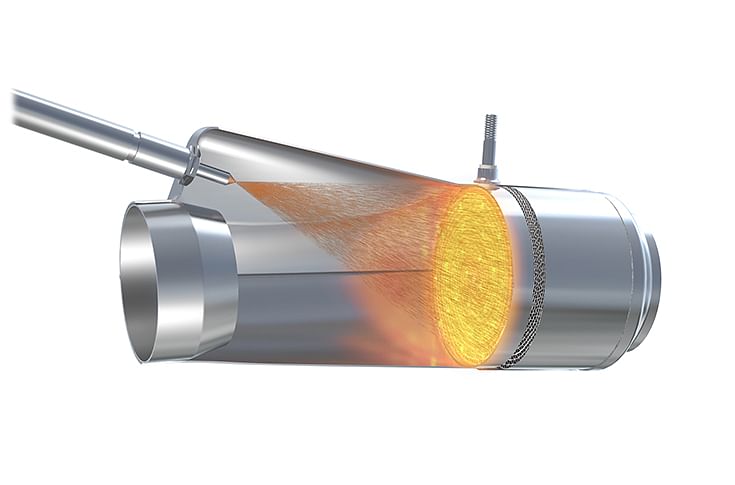

Injection of fuel: This is a very efficient method because the heat is directed only where it is really needed.

Presti further explains, “The challenge is to ensure that the exhaust system is heated as quickly as possible to a temperature where NOx conversion can start. Close-coupled mounting of the catalysts (oxidation catalyst and SCR catalyst) is a good strategy for ensuring that waste engine heat reaches the catalyst components as quickly as possible. For the same basic engine, the catalysts used must be easily adaptable to a wide range of construction machines.”

Asymmetrical catalyst for reduced precious metals

Continental’s new ‘concertina-type folding technique’ for metallic substrates makes it possible to implement asymmetrical catalyst dimensions that are more closely adapted to the available packaging space. Using the slanted metallic CS substrate (CS = crossversal structure), which dispenses with a smooth intermediate layer, it is also possible to achieve an approximately 20 percent reduction in mass. At the same time, the turbulence-generating CS foil structure improves the efficiency of the catalysts, with benefits particularly in terms of reducing the amount of costly precious metal that needs to be used in the substrate. “Substrate geometries that allow close-coupled mounting of the catalyst is a powerful design tool for customers,” says Presti.

The turbulence-generating CS foil structure improves the efficiency of the catalysts.

By developing heat quickly, electrically heated catalyst elements can serve a ‘stopgap’ function until other heating measures come on stream. These electric heating substrates can either be mounted as diesel oxidation catalyst or can be integrated in the SCR catalyst. A further intelligent solution would be to inject fuel into a mixing pipe, with subsequent catalytic conversion into heat immediately upstream of the catalyst. “This is a very efficient method because the heat is directed only where it is really needed, rather than simultaneously heating the entire thermal mass of the exhaust system,” Presti adds. Continental consfirms that these two strategies – electric heating and fuel injection – can also be used in combination.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

19 Mar 2019

19 Mar 2019

6019 Views

6019 Views

Ajit Dalvi

Ajit Dalvi