Chiyoda Corp and Toyota to jointly develop large-scale electrolysis system

Strategic collaboration to fuse fuel cell and plant construction technologies for hydrogen production markets in Japan and overseas. The goal is to develop an electrolysis system with high hydrogen production efficiency while being the world's smallest in size.

Chiyoda Corporation and Toyota Motor Corporation have today agreed to jointly develop a large-scale electrolysis system and construct a strategic partnership and have signed a basic agreement on cooperation.

The goal is to contribute to achieving the Japanese government targets for the introduction of electrolysis equipment both in Japan and overseas as part of the Basic Strategy on hydrogen formulated by the government.

The production and mass production technologies for electrolysis cell stacks using the fuel cell technology held by Toyota and the processing plant design technologies and large-scale plant construction technologies held by Chiyoda will be brought together to develop a large-scale electrolysis system that can be competitive. This will allow adaptation to the rapidly expanding hydrogen production markets both inside and outside Japan.

Specifically, the goal is to develop an electrolysis system with high hydrogen production efficiency while being the world's smallest in size.

The two copanies' goal is to develop an electrolysis system with high hydrogen production efficiency while being the world's smallest in size.

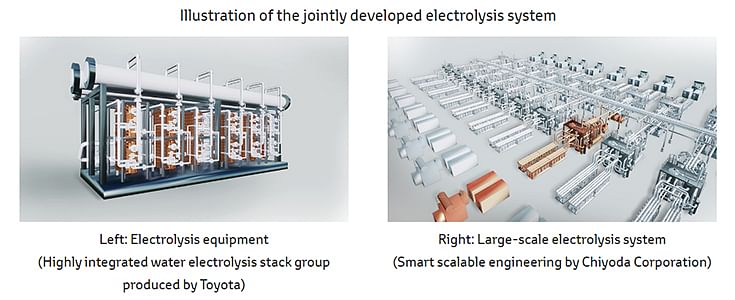

To be able to respond to the various needs of customers, such as the amount of hydrogen used or limitations on plant floor area, 5 MW-class equipment will be used as the basic unit (floor area: 2.5 m x 6 m, hydrogen production capacity: approx. 100 kg/hr) for development, and will be combined to create a standard package, allowing the construction of large-scale electrolysis systems.

The merits of this equipment include the fact that it only takes up about half the floor area of conventional equipment and offers ease of maintenance while allowing easier shipping, shortened on-site construction times, and lower civil engineering and construction costs. Toyota's particular expertise in industrial products and Chiyoda's particular expertise in plant engineering will be combined and optimized, allowing benefits such as lower costs, increased production efficiency, and more stable quality for the electrolysis systems required to produce green hydrogen.

With the signing of this basic agreement on cooperation, the introduction of an electrolysis system in Hydrogen Park at the Toyota Honsha Plant will start in FY2025. It will be expanded in the future to the 10 MW class and used for verification and development. Any further developments will be released as they happen.

Images: Toyota

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

By Autocar Professional Bureau

By Autocar Professional Bureau

05 Feb 2024

05 Feb 2024

4067 Views

4067 Views

Ajit Dalvi

Ajit Dalvi