BMW readies radical battery technology for 2026 launch

New tech will make them lighter and boost their capacity, says BMW.

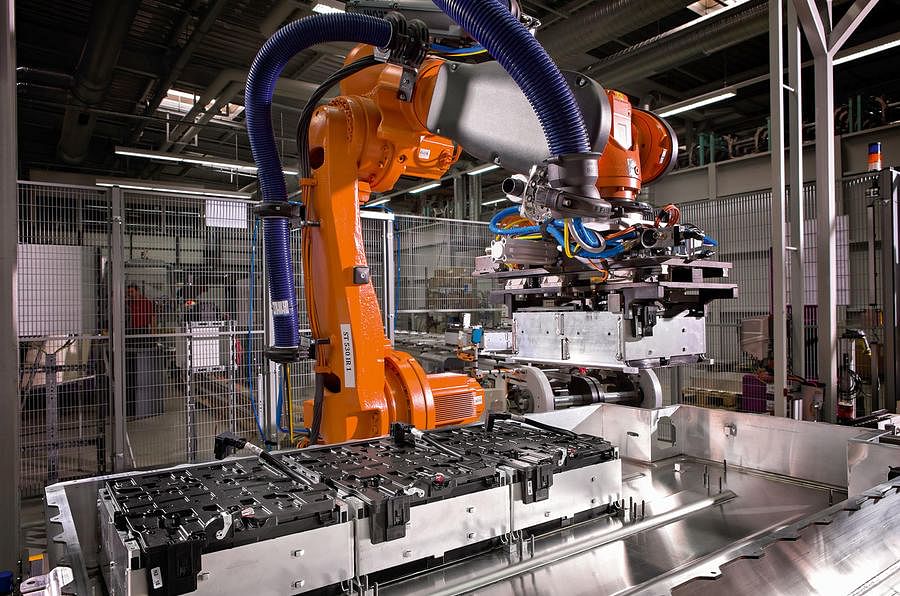

BMW expects a breakthrough in battery technology in 2026, by which time it plans to have solid-state batteries ready for production in its models.

The batteries will use lithium ion technology but swap liquid electrolytes for solid ones, with initial targets being for a 15-20% increase in capacity.

Other benefits include less weight and a reduction in the amount of safety protection needed due to the reduced fire risk. This also allows for the packaging and housing of the batteries to be revisited.

The batteries are in development but 10 years away from production, with long-term durability testing cited as a key reason for the delay.

The next development in the refinement of BMW’s existing battery technology will arrive in 2018 in time for the launch of the Mini Cooper E and the all-electric version of the next-generation BMW X3.

BMW will continue to develop its internal combustion engine technology, which is predicted to remain the most popular power source for its models until at least the end of the next decade. The firm wants to improve the efficiency of its engines to 33%, compared with the 90% efficiency of its electric drivetrains.

Sales and marketing boss Ian Robertson said: “The internal combustion engine has a long way to go. We will improve the efficiency and mate them to electric vehicles in many cases.

“Plug-in cars are faster, quieter and better accelerating but set new benchmarks for CO2 and economy. It’s all moving in that direction for legislation. We will drive to improve [engines] alongside electric powertrains.”

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

14 Feb 2017

14 Feb 2017

3794 Views

3794 Views

Ajit Dalvi

Ajit Dalvi