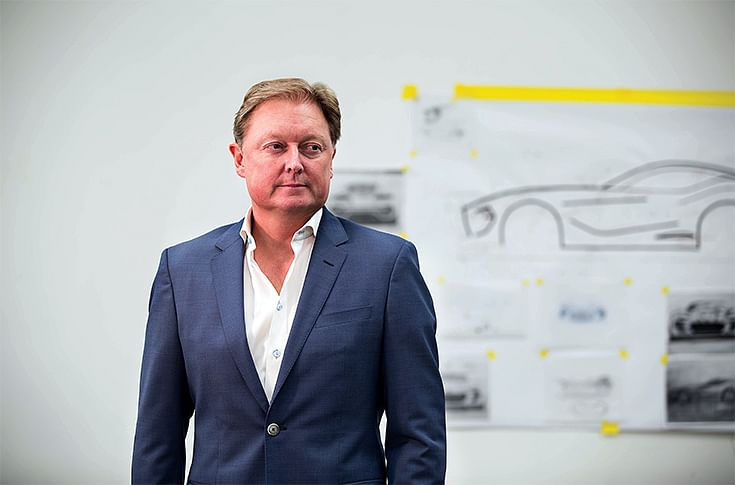

Henrik Fisker: ‘We’re keen to set up a tech centre in India, a battery factory and vehicle assembly too.’

One of the world’s most prolific car designers and entrepreneurs and wants to change the paradigm of mobility with non-conformist and extreme electric vehicles.

The Chairman and CEO of Fisker Inc is one of the world’s most prolific car designers and entrepreneurs and wants to change the paradigm of mobility with non-conformist and extreme electric vehicles. He lays out his vision for the future, which could include make in India through a manufacturing partnership, while also offering top tips to develop India’s electric vehicle industry.

You have been behind the success of a number of luxury vehicles and have worked with many carmakers including BMW and Aston Martin. What are the challenges that you have come across in terms of vehicle design?

With traditional car manufacturing companies, the challenge is to be able to ‘think out of the box’ – and change the fundamental proportions of a vehicle. The challenge of designing any car is to decide on the compromises such as aerodynamics versus looks, interior space versus good proportions, and integrating technical and functional aspects into a cohesive design.

In terms of global automotive trends, which ones do you think will be prominent in the future?

The trend is moving towards cleaner surfacing on the exterior and simpler interior designs with fewer buttons and larger touch-screens. We are also seemingly moving away from traditional three-box sedans and back to hatchback styles and crossovers.

Electric vehicles have been around in developed markets for some time now but have yet to make a dent in overall auto sales. What do you think would be the facilitator to greater adoption of EVs?

Definitely, the battery. We must move to solid-state batteries with higher energy density, faster charging and safer operation. At Fisker Inc, we have already filed several patents (on the Fisker Flexible Solid-State Battery) and are working on bringing solid-state batteries to market in 2020. We believe this will drive wider adoption of EVs (they will become more practical), as well as affect the way we charge consumer electronic devices at the same time.

In terms of mass-volume acceptance, traditional IC engines are seen to continue their growth for the next few decades. Do you think with the huge global vehicle parc, there would be enough room for both ICE vehicles and EVs to grow at the same pace?

No, ICE vehicles will likely decline dramatically after 2025, and EVs will continue to grow in dramatic fashion from 2022 on forward.

You had showcased the EMotion at CES 2018. When will commercial sales begin?

Sometime in 2020: it depends on when our Fisker Flexible Solid-State Battery technology is ready. That will drive the launch date.

For EVs, despite their many benefits, range and recharging time play a crucial role. But from the purview of developing countries, the challenges are manifold. Do you think EVs might remain a rich-man’s vehicle?

EVs will be available for everyone at some point down the line – and when Solid-State Battery technology hits the mass market, EVs may eventually be cheaper than ICE vehicles.

How do you see the electric mobility scenario globally and what is your view on India’s ambitious plan for a high level of EV adoption?

India has the unique opportunity and possibility to go all-electric very quickly, as the country doesn’t have a massive, advanced ICE vehicle industry to change. The current Indian car industry has the choice to either invest into new, modern ICE vehicles or invest in EVs. India’s government has the ability to drive the country towards EVs which, I believe, would be the right thing for India. Otherwise, India risks falling behind China, and the rest of the world. I believe the country should provide government support for new EV companies to bring technology and EV car manufacturing to India, which would accelerate the entire Indian economy and make the country a global player in EV technology and manufacturing.

The Fisker EMotion luxury electric sedan has a claimed range of over 400 miles / 640 kilometres and a top speed of 161mph/258kph. It is slated to be launched with an LG Chem lithium-ion battery cell in 2020.

The government would also have to invest in charging infrastructure to make sure the market will continue to grow with investments made by private companies into EV manufacturing. The next 24 months will be crucial – and those countries which invest into EV growth will be at the forefront of global momentum.

In terms of contribution from India, apart from CAS Modelling, are there any other companies that you are working with?

We are looking at setting up a tech and software centre in India. If there were government support, I would consider eventually setting up an advanced battery factory and vehicle assembly centre for our lower-cost, high-volume vehicles. But we would need to see a clear charging infrastructure strategy from the government.

We have already been approached by several Indian companies that want to partner and invest into Fisker to come to India but, without a clear strategy and/or financial support from the Indian government, it’s too early to make these decisions. China is quite a bit more forthcoming and moves significantly faster. However, it’s my goal to eventually set up a larger business in India, as I fundamentally believe that the Indian consumer appreciates high-tech and clean vehicles.

You are scouting for a partner in the Indian market. Can you detail your key parameters in a partnership?

We are not in a hurry, as we are concentrating on our business in the US market. But, an eventual partner must be financially strong and be able to invest into a partnership which would consist of manufacturing first and foremost. We will not have a distributor/importer for our upcoming vehicles in India. Any imported vehicles would be sold directly by Fisker Inc.

Fisker’s solid-state batteries will feature three-dimensional electrodes with 2.5 times the energy density of lithium-ion batteries.

At Fisker, we are also developing our proprietary Fisker Solid-State Battery, for which we have filed more than 15 patents. This technology is lowering the cost of batteries by more than 50 percent – and producing them in India could be a future possibility to lower cost even further. But this would only make sense if we also manufactured an EV in India. No firm manufacturing plans have been made in any of these areas as of yet.

What role will the proposed technology and software centre in India play in Fisker Inc’s global scheme of things?

A future Fisker Inc software centre in India would theoretically support Fisker Inc’s headquarters in Los Angeles, California.

Along with the EMotion electric luxury sedan, you have said there will also be a second, higher-volume and lower cost model to follow. Do you have India and APAC in mind for such a model?

Announcements on our second, high-volume and affordable vehicle will follow later this year.

Many global OEMs have R&D and tech centres where Indian engineers are actively engaged in AI operations. Do you plan something like this in your facility?

Yes, that would be part of an eventual tech and software centre, when we open it.

You have recently joined the Board of Motec Ventures to facilitate increased collaboration between promising new suppliers, SMEs and OEMs in an effort to lower manufacturing costs and enable smarter scale-up? How do you plan to do this?

I’ve been fully engaged with the Motec Group and have had several discussions where we’re already reviewing new start-ups. We study the start-up’s technology – and I particularly see if it’s applicable to any of the future programs at Fisker Inc, as well as the larger global automotive industry. If we see that the start-up can contribute to part of the supply chain with a breakthrough idea, Motec will invest into the start-up and we use our collective network to help the start-up grow.

If the technology is applicable to any of Fisker Inc’s future products, Fisker Inc may participate in the investment round and engage with the start-up directly. The automotive industry is changing forever, where much shorter development cycles and faster go-to-market processes are necessary to be successful.

By working with new start-ups, extreme short development cycles are possible, as they are not bogged down by traditional and long automotive processes – they must be faster to succeed. Several new technologies can be developed and tested faster today, due to extensive use of new software, and if an OEM can make fast decisions, the technology can be implemented much faster. The days of 3.5-plus- year development cycles are over – it’s too long of a time period for the product to stay relevant.

From your experience, what can you suggest as the path ahead for budding automobile designers?

Attending an international design school like Art Centre College of Design, Pasadena, CA (USA). In your first job out of school, make sure you spend a lot of time with the engineers to understand how to solve problems – as well as learn generally how a car is really engineered and built.

What or who has been your source of inspiration? Could you also share the thought that goes beyond designing a vehicle?

My first inspiration was Giorgetto Giugiaro – the prominent Italian designer – and his amazing concept cars he did in the 1970s. Today, I find inspiration from different futuristic product designs, and once in a while I look at some of the beautiful historic cars – especially from the 1960s.

Henrik Fisker: "It’s my goal to eventually set up a larger business in India, as I fundamentally believe that the Indian consumer appreciates high-tech and clean vehicles."

The most important inspiration is the fast-moving culture surrounded by connectivity dominated by the smartphone. This makes me think about what type of mobility people will need and ‘want’ in the future.

Many predict that future mobility will see more of demand-driven shared, autonomous and connected vehicles, thus changing the ownership model for vehicles. Do you think this pattern would disrupt how automobiles are designed, manufactured and perceived?

I think we will see the most dramatic change happening in the next seven years. Car companies and their brands will no longer be defined by the performance or the type of cars they make – rather, their brands may be defined by the type of mobility experience they offer. We will see a combination of shared and ownership models. However, ownership will demand different/unique vehicle attributes and sharing will develop into multiple experiences and price classes.

I don’t think ownership will decline much: people will always see cars as a status symbol, and personally-owned transport is a sign of wealth and success. That said, people will use their personal vehicle less and use shared mobility for shorter trips – especially in large city centres where there is a major need to relieve congestion. You can look at it this way: people will always have their own kitchen at home, even if they choose to eat out more!

What, in your opinion, will be the popular lightweight material that could find use in the car of the future?

Aluminium and carbon fibre will find their way into more affordable vehicles in the future.

What are your top 5 tips to develop the fledgling EV industry in India?Only three things are necessary to make India an active EV player:

- Local Indian industry must engage with the Indian government to lay out a charging infrastructure strategy and an electric vehicle incentive strategy.

- Financially strong Indian businesses (they do not have to be automotive) must partner up with international EV entities to develop and manufacture EVs for the global market. The traditional thinking of making specific electric vehicles for India does not work! To achieve economies of scale in a market that will remain small in the foreseeable future, the EVs made and sold in India must be based on a global vehicle (that could be customised for the Indian market). The great deal that it takes to develop and produce a high-tech affordable electric vehicle, is often underestimated.

- The key over the next 10 years is to achieve economies of scale, especially on expensive EV components like batteries. With large investments going into developing EVs, the technology must be state-of-the-art so that the final product can survive in a fast-developing market. It’s also important to get access to new battery technologies, as they will be the key to lowering the cost of future EVs. All this can only be achieved by making EVs for the global market. Going global and certifying future EVs for the global market is a ‘must’

to succeed.

(This interview was first published in the 1 September 2018 issue of Autocar Professional)

RELATED ARTICLES

INTERVIEW: "EV Demand is Rebounding both in India and Around the Globe" - JLR's Rajan Amba

Jaguar Land Rover India MD Rajan Amba discusses the India–UK FTA, the company’s manufacturing plans, the upcoming Panapa...

TVS Celebrates 20 Years of Apache, Eyes Premium and Global Push

Marking two decades of its flagship performance brand, TVS Motor unveiled special anniversary editions on Saturday while...

Q&A: Mahindra's Nalinikanth Gollagunta on Upcoming Festive Season, 'Bold' Design Choices

Automotive Division CEO Nalinikanth Gollagunta says mid-teens growth is achievable with Roxx ramp-up, BEVs, and a resil...

18 Nov 2018

18 Nov 2018

30063 Views

30063 Views

Prerna Lidhoo

Prerna Lidhoo

Darshan Nakhwa

Darshan Nakhwa