'Centre should lay policy and let industry decide the tech (for clean mobility).'

The Automotive Mission Plan has already projected something like 12-13 million vehicles and going on to 2030 we are looking at 15 million vehicles.

As India drives towards an era of mass scale electric mobility, the automotive industry is set to see a lot of action. The government also has to pitch in to build a sustainable EV industry. Rattan Kapur, ACMA's outgoing president and CMD, Mark Exhaust Systems, speaks to Sumantra B Barooah about the evolution of the industry and the government's role in it.

Electro-mobility was a much-discussed topic at the ACMA and SIAM conventions this year. It's no longer a question of whether it's happening. It's about when and how. But there is also a view that instead of a prescriptive approach, there should be targets set for industry to meet using whatever technology it may find most suitable. What is your take?

The government should lay down a policy. It should not be talking about what technology to adopt. That should be left to the industry to decide. So the government should clearly say, "Look, today you’re at 170-180 (gms/ km) CO2 emission, NOx levels, please bring it down to 120 by 2020, to 100 going forward and finally to 50-60 level by 2030.” That way, we will know exactly what the government has asked from us and what is expected from us. We could use multiple technologies to achieve these NOx levels and also then exhaust the investments that we‘ve already made, so it gives us time. However, the government is in hyper mode.

We agree we are going electric for the sake of the country to reduce pollution. I can't stand on a road without a mask on my face, it's terrible. But there has to some way we have to find in this total madness, what is best for India, what is best for our investments. That I leave to the carmakers to decide what technology they should bring in.

We have seen a lot of activity by various suppliers in the form of JVs and other partnerships. Also, they are making efforts to be self-reliant in technological capabilities. Where has the industry reached in the evolution curve?

Our focus till now has been on Euro 4 (BS IV) and now going into Euro 6 (BS VI). Our total focus and investment and R&D efforts are towards this. But suddenly the disruption is taking place in China and USA; the focus of the total industry in America has shifted from Detroit to Silicon Valley. The startups there it suits them, suits their philosophy, it suits the way Americans want to lead the world. It suits China because they produce lithium. India does not produce lithium. India doesn't have a Silicon Valley. India is nowhere there. We are struggling to go from Euro 4 to go to Euro 6. It's virtually impossible to convert by 2030. A 100 percent conversion is impossible but if there is a step-up approach, I am sure the industry will come back and tell the government, 'Yes, if the battery conditions are conducive we will go electric. By 2030, maybe 30 percent is possible'. Do note though that the volumes are going up.

The Automotive Mission Plan has already projected something like 12-13 million vehicles and going on to 2030 we are looking at 15 million vehicles. So if I look at 15 million vehicles and 30 percent, it means 5 million vehicles on the road. Mind you, these are not two- or three-wheelers. This number is only about (electric) four-wheelers, commercial vehicles.

That would have a significant impact on the environment.

We must realise today that there are a big number of two-wheelers on the road. Eighteen million units were sold against three million cars last year. The pollution levels coming out of twowheelers may be little bit more than what fourwheelers emit. So, it’s a good idea and much easier for two-wheelers to convert (to electric) than for buses and CVs, maybe for the trucks to convert if charging stations can be built en route once they get over the charging issues.

A step-by-step approach has to be drawn up. After Mr Nitin Gadkari's statement at the SIAM Convention, I spoke to the secretary, Ministry of Heavy Industries to understand clearly what’s in the minister's mind. We totally support it. Whether he wants it or not we want it, but let's see how we can achieve our goals in a more sensible and practical manner.

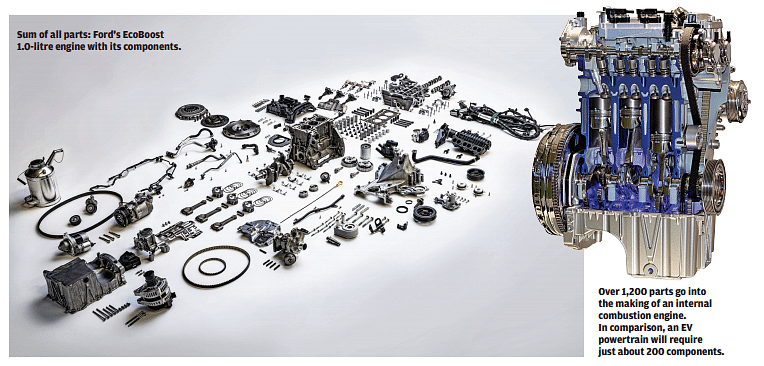

The transition to electric mobility could also lead to some major disruptions in the manufacturing and supply chain. The technology quotient in EVs is high but they have lesser parts and are less labour intensive. What kind of repercussions do you see in the component industry and the impact on the employment level?

the employment level? There could be a huge impact on direct employment, when you consider that over 1,200 parts go into making an internal combustion engine and maybe 200 into making an EV powertrain. Therefore, many of those companies, if they do not find some alternate businesses, will have to shut down and that's going to be hard on the labour front. But I don't think that's going to happen as the IC engine will continue for 10-15 years and then it will slowly start coming down.

Right now, there won't be so much of an impact on the labour front. The labour impact will come when we go totally electric, 2025-2030 onwards. Normal factories, which would employ 100 staffers, will employ only 20-30 people. There will be more focus on engineering, design and qualified people. Let's say, on an average, a minimum hit is going to be 50 percent, so whatever the government is projecting employment for 2025-2030 is going to be divided by two.

Therefore, shouldn't the government also focus on skilling people to be employable elsewhere?

There will automatically be other opportunities because when you go into electric vehicles, there are other businesses like battery charging stations which will need people to monitor them. There could be various types of battery charging methods– by driving or replacing your batteries change over in 2 minutes. A lot of skilled and semi-skilled employment could be absorbed there.

Yes, jointly between the government and us, there could be a way that our absorption level could be more or less the same. But far as manufacturing units go, they will surely take a big hit.

As a supplier yourself, what kind of expansion are you looking at in terms of investments or venturing into adjacent segments or new opportunities which you see?

As far as Mark Exhaust goes, we took a good decision two to three years ago to expand our range of products from exhaust systems. So we’ve gone into body in white. We manufacture the complete body in white for most of the Mahindra models now. Then, we have also acquired Delphi India's shock absorber business. That gives us another avenue. We are looking for an international name to support us in technology for future requirements.

I don’t think cars will be made of steel. When you are making electric cars, I am sure there's going to be a lot of further scope for lightweighting. We will have some scope for roll forming and in aluminium. That’s how I see my company going forward. Yes, exhaust will finish!

(This interview was first published in the October 1, 2017 print edition of Autocar Professional)

RELATED ARTICLES

INTERVIEW: "EV Demand is Rebounding both in India and Around the Globe" - JLR's Rajan Amba

Jaguar Land Rover India MD Rajan Amba discusses the India–UK FTA, the company’s manufacturing plans, the upcoming Panapa...

TVS Celebrates 20 Years of Apache, Eyes Premium and Global Push

Marking two decades of its flagship performance brand, TVS Motor unveiled special anniversary editions on Saturday while...

Q&A: Mahindra's Nalinikanth Gollagunta on Upcoming Festive Season, 'Bold' Design Choices

Automotive Division CEO Nalinikanth Gollagunta says mid-teens growth is achievable with Roxx ramp-up, BEVs, and a resil...

24 Oct 2017

24 Oct 2017

5508 Views

5508 Views

Prerna Lidhoo

Prerna Lidhoo

Darshan Nakhwa

Darshan Nakhwa