‘Germany and India complement each other quite well and by utilising each other’s strengths in different areas, we can overcome possible challenges’

Business needs a predictable and stable environment for investments and an FTA would provide such a framework. It would reactivate terminated investment treaties to provide security for European investments in India and Indian investments in Europe and Germany.

The managing director of the Bangalore-based EFD Induction was recently awarded Germany’s Cross of the Order of Merit for his outstanding contribution to Indo-German relations. Having spent over three decades in India, he details the growing connect between the two countries, the need for an FTA between India and the EU, how industry academia collaboration can be expanded, and what keeps him bonded to India. An email interview by Kiran Bajad.

Congratulations on being awarded the highest tribute of the Federal Republic of Germany — the ‘Order of Merit`— earlier this year. You have been in India for over 30 years, working towards promoting business, cultural and social ties. What are the five things that stand out in this journey?

Thank you. I see this award as a recognition for all friends, Indians and Germans alike, who were involved in promoting India-Germany ties and supporting a number of social projects as well.

A key point I would like to highlight is the ‘Shanti Bhavan’ residential school project, started by an Indian entrepreneur, Dr George, around 20 years ago. This school provides high-level education for around 250 children with financially poor parents. These children are a great inspiration for everybody who has the privilege to work with them.

The second highlight is a tribute to friends and former colleagues at ISRO, where I was working from 1987 to 1994 as a project manager on behalf of the German space agency, DLR, before I joined EFD in 1995. Their professional knowledge and enthusiasm do bring India forward and their technical and personal support for me was exceptional.

The third key point is the development of our company, EFD Induction. The start was just after the India opened up for FDI in 1991. It was not easy and we had to overcome bureaucratic hurdles and plenty of technical challenges. Without the remarkable engagement of our employees, the support of our suppliers, first customers like TVS in Hosur and Canara Bank, we may not have survived this initial period. We were able to stabilise the company after a few years and the rest is history; we became a recognisable force in the field of induction heating in India and Asia.

Then there's the good co-operation with government agencies, industry organisations like the Indo-German Chamber of Commerce and the German Consulate in Bangalore. These networks are essential, especially for medium-scale businesses, to address problems and to solve them in a reasonable timeframe.

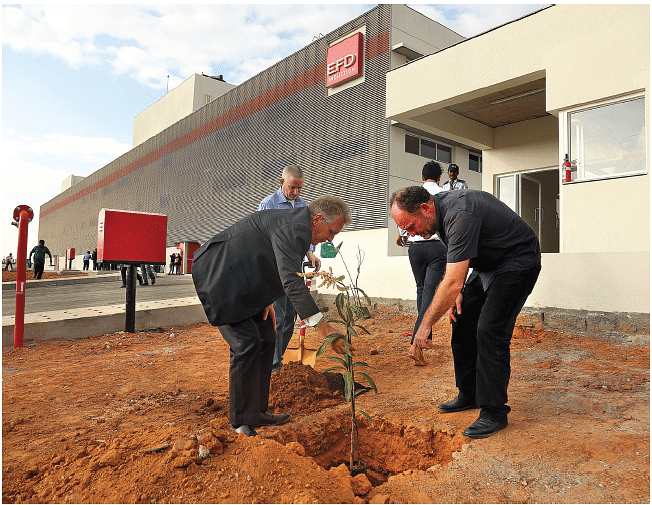

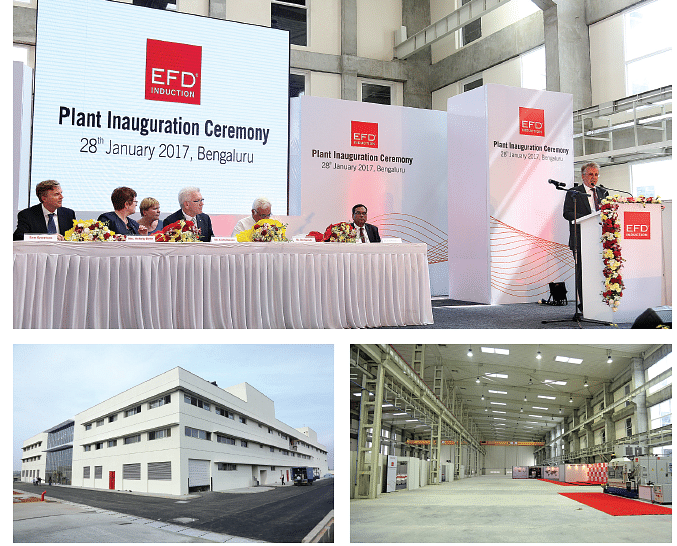

Last but not the least, I would like to mention our new factory building in the Aerospace Park in Bangalore. We were able to build one of the most advanced manufacturing units combining traditional knowledge of climate control with the latest computer simulations to ensure an energy efficient operation.

Last month, Prime Minister Narendra Modi and German Chancellor Angela Merkel set the roadmap for future bilateral strategic ties at the fourth India-Germany Intergovernmental Consultations in Berlin. Germany is India’s largest trading partner in the European Union and one of the leading sources of FDI. At present, there are over 1,700 German companies and 600 JVs in India, many of them in the automotive sector. What, in your opinion, should be done to further drive bilateral ties?

I was part of the delegation of the Indo- German Chamber of Commerce to the fourth inter-governmental consultations between India and Germany in Berlin and I believe that the consultations were a big step forward to develop our co-operation further. In the joint statement during the visit of the prime minster to Germany, it was reiterated “that the Indo-German Strategic Partnership is based on common values of democracy, free trade and a rule-based international order and that it has strengthened the bilateral relations by further enhancing trust and mutual respect”.

Co-operation in the field of developing smart cities, supporting vocational training based on the German dual system and facilitating start-up companies in both the countries are, in my opinion, key drivers for bilateral ties. Twelve MoUs in fields like digitalisation, training, health, railways, urban development and other areas were signed during the visit.

The proposed FTA between India and the European Union is yet to happen. What are the key benefits and concerns to industry, particularly automakers in India?

Business needs a predictable and stable environment for investments and an FTA would provide such a framework. It would reactivate terminated investment treaties to provide security for European investments in India and Indian investments in Europe and Germany. An FTA between India and the European Union would be a powerful statement at he right time for the system of free trade in a time where Donald Trump is questioning the benefits of globalisation and free trade. Also, when China is pushing for a Sino-centric trading system with its ‘One Belt One Road’ infrastructure plan, where India did not participate in the summit in China and Europe did not sign the trade document for obvious reasons.

Therefore, I believe we should not focus only on tariffs and import duties for automobiles, wine and spirits, but also on the big issues to set the framework for trade and investments including standards, investment treaties and free, safe and protected exchange of data.

The negotiations, in a deadlock since 2013, should resume soon and I am a bit optimistic that we can make faster progress now, facing more challenges and tendencies of protectionism.

How would you define the key strengths of Indian and German companies and their meeting point?

This depends, to a good degree, on the business area as well as the business model of the respective companies. In general, India is strong in low-cost manufacturing and advanced software while Germany is strong in engineering and advanced manufacturing.

Nothing is static, Indian companies will face some competition by other low-cost countries like Vietnam or Indonesia, but even more from very advanced manufacturing destinations due to a high degree of automation.

Germany has challenges as well. We focus on high-quality products but we need to understand that this is not enough. We have to address the need for mobility and not just on making a good car. People want different modes of mobility to reach a destination fast and cheap, but this does not mean that they need their own car. It could be a combination of public transportation and Uber/Ola services or self-driving cars in the future.

If we utilise and combine the strength of Indian and German companies, we have a pretty competitive combination.

German automakers have made considerable headway in the automotive and manufacturing technologies of the future like autonomous vehicles, artificial intelligence, Industry 4.0 and 3D printing.

Yes, no doubt. However, the competition will increase and disruptive technology changes like electric cars provide challenges in the future for car manufacturers and suppliers like us alike.

What, according to you, is the scope for industry-academia collaboration in India?

The scope is significant and I will detail a few areas:

l India has a big need for trainers for dual vocational training. This is essential if we are to provide jobs for 10 million young people every year.

l We have to integrate students much faster into the industrial process than in the past. Therefore, they have to be exposed to the needs of the industry during their studies.

l We need more investments in research and development to keep the industry competitive in the global market. This includes co-operation with universities and research institutions.

l Emissions standards for cars and trucks will become very demanding in a short span of time. This requires local R&D and engineering to achieve these high standards without increasing the cost too much to keep cars affordable. At the same time, it provides good opportunities to supply cars and components in the world market since they would meet global standards.

Which are the areas, in the automotive space, that can benefit from induction technology, and how?

The major application in the automotive space is induction hardening of critical mechanical car components. This includes engine components like valves, cam- and crankshafts, steering racks, gearbox components and parts of the drive system like driveshafts, tulips and outer races.

The parts are heated by induction to around 900deg Celsius and subsequently cooled at a rapid speed to room temperature. This changes the microstructure of the steel and makes it hard, strong and wear resistant.

We harden only the segments where hardness is needed, for example where a bearing is running. This is a big advantage since unwanted segments are not hardened to avoid brittleness.

There are many more advantages. We do not need chemicals in the hardening process; the hardening machines can be integrated into manufacturing sequence.

Induction hardening plays a vital role in modern cars for high safety and a reasonable long lifetime in a range of more than 150.000 kilometres.

How has EFD Induction grown over the years and what is the growth game-plan for the near future?

Over the past 20 years, we have made CNC-controlled hardening machines popular in India. This was needed for the automotive component industry to get a high level of reproducibility.

In addition, we integrated all kinds of sensors to keep good control on the machine performance and the hardening process. Almost all cars on Indian roads run on EFD technology.

We introduced induction brazing in the electro-technical industry for making transformers and electrical motors. This has increased their safety and performance significantly.

As in the past, we will compete based on the quality of our equipment, our knowledge of the hardening process and improved service, both in terms of quality and speed.

EFD Induction has moved to a new facility. What are the new introductions planned by the company in India? What is the current turnover, and what are you targeting by 2020? How many OEMs and suppliers in India are your clients?

Yes, we have moved to our new facility at the Aerospace Park south of the Bangalore airport. This modern factory will allow us to produce our machines faster and better. All sub-assemblies and our generator manufacturing are located around the central assembly bay and ensure an efficient flow in the assembly process.

We will be able to expand in India, extend our footprint in parts of Asia and support our group with components and services. We want to grow at 15 percent on average and we will learn how to utilise our new facility more for the benefit of EFD India and the EFD Group by expanding in our traditional areas and to explore new market segments and technologies. All major passenger car component suppliers in India are our customers.

How can ‘Make In India’ and ‘Made In Germany’ come together for a common program?

Prime minister Narendra Modi made a strong statement during his recent visit to Berlin: “We are made for each other. We are looking at outcome-oriented momentum in India-Germany ties and a quantum jump especially in economic ties”.

As mentioned and elaborated above, we (India and Germany) complement each other quite well and by utilising each other’s strengths in different areas we can overcome possible challenges quite well.

This is based on a common value system, democracy and free trade, and therefore forms the basis for a long-lasting relationship.

You are due to retire this year, having spent 30 years in India. How you view your journey here and India’s progress?

It has been, all in all, a quite remarkable journey. I had the support of wonderful people who helped in good times and, even more important, in not-so-good times.

I married my Indian wife in the year 2000 and we have a 12-year-old son. They have been my backbone throughout this journey.

Last year, I was appointed president of the Indo-German Chamber of Commerce and received the ‘Order of Merit’, which makes for a nice ‘rounding up’ of this part of my life.

India is now on the way to becoming a world power and I am thankful that I could witness all these changes over the past three decades.

(This interview was first published in Autocar Professional's 1st July Issue)

RELATED ARTICLES

INTERVIEW: "EV Demand is Rebounding both in India and Around the Globe" - JLR's Rajan Amba

Jaguar Land Rover India MD Rajan Amba discusses the India–UK FTA, the company’s manufacturing plans, the upcoming Panapa...

TVS Celebrates 20 Years of Apache, Eyes Premium and Global Push

Marking two decades of its flagship performance brand, TVS Motor unveiled special anniversary editions on Saturday while...

Q&A: Mahindra's Nalinikanth Gollagunta on Upcoming Festive Season, 'Bold' Design Choices

Automotive Division CEO Nalinikanth Gollagunta says mid-teens growth is achievable with Roxx ramp-up, BEVs, and a resil...

05 Aug 2017

05 Aug 2017

17682 Views

17682 Views

Prerna Lidhoo

Prerna Lidhoo

Darshan Nakhwa

Darshan Nakhwa