Inspecting the first Aston Martin DB11s with CEO Andy Palmer

Aston Martin CEO Andy Palmer is approving the first 1000 DB11s personally. You get to see him in white-gloved action – and learn why he’s doing it.

For the past few weeks, and many to come, Aston Martin CEO Andy Palmer has been stopping his day job at 6pm.

He then heads for the Aston Martin production line, just a minute or two from his Gaydon office, walks into a glass room and slides on a pair of white cotton gloves. With these, he will caress certain parts of whichever DB11 happens to be presented to him, devoting a good 40 minutes to the task. He will perform the same ritual with three or four DB11s in an evening, and every 10th car he will take for a short, low-speed test drive around an unusual road laid in Aston Martin’s back yard.

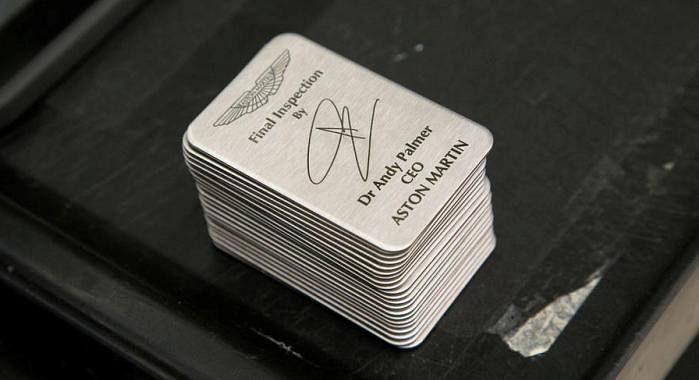

Palmer is fulfilling a promise. Back in July, he announced that he would personally inspect the first 1000 DB11s off the production line. If the car passes, he will attach his own name-checked plaque to its engine cover, the Aston’s first owner receiving a letter detailing Palmer’s email and mobile number, should they be unhappy.

“What I’m looking for,” he says of a visual inspection process supplementing a one-hour test including mechanicals and electronics, “is stuff we’ve had issues with.” He starts by working his way “around the exterior, checking gaps, flush and overflush”. If you’re slightly baffled, gaps are the spaces between panels, while some panels are meant to sit flush with one another and others are arranged deliberately to stand fractionally proud, or overflush.

Palmer starts at the top, his gloves gliding over the roof and its boundary with a pair of strakes. These pieces flow from the base of the A-pillars to flank the roof before flaring to an elegant halt over the rear deck. They’re mounted on their own carriers, early DB11 strakes sometimes betraying small domes where clips met carrier. A cotton-gloved hand will detect these subtle protrusions; that’s why Palmer is “checking the profile of the roof strake”.

Next stop is the passenger door. Palmer repeatedly opens and closes it to hear the panel thump home. “It's overflushed because of dirt build-up,” he explains, pointing to a door trailing edge that sits slightly proud of the rear wing. He also closes the door with its handle held open. If there are metallic noises, the door catch is probably snagging. But no such sounds emerge and Palmer declares this door “particularly good”.

He should know, this being the 83rd DB11 he’s inspected. He certainly looks practised as his scrutiny turns to the Aston’s rear end. “I carry these with me everywhere,” he says, producing an evenly pronged disc, about the diameter of a doughnut, and a small rectangular block. Each of the disc’s prongs is marked with its thickness – 1.0mm, 2.5mm, 3.5mm and so on – enabling the accurate measurement of panel gaps. The small block uncovers any flush irregularities. The prongs reveal a 3.5mm gap on one side and 3.0mm on the other. Palmer refers to a neatly presented app on a tablet on which every tolerance value can be found, complete with images. These are within limits.

So are the gaps around the high mounted stop light, but Palmer notes some residual polish beneath a window and declares the closing performance of the driver’s door “just okay”, the panel not shutting quite as cleanly as its opposite number. Next up is the clamshell bonnet’s underflush to the front wings and its relationship to the bumper. “It’s the hardest thing on this car,” he says. “It’s a huge panel, with lots of tolerances.” The gap on one side is 4.0mm, the other 3.5mm – a pass.

Then Palmer uncovers a fault and an inconvenient one at that. There’s a paint flaw on the bonnet, like a faint birthmark. “We take more than 100 hours painting these cars,” he says, “so we make sure they’re perfect.” Perfecting this panel will take considerable skill and some effort.

Up next is the interior. Door seals are surveyed to ensure that their lips haven’t folded beneath the trim that they should overlap. Every button is pressed, the knob turned and paddle pulled. The sunvisors’ vanity mirror sliding covers are slid, because “they need to move with the right force”, and the electric seats motor about in the search for unseemly grinding. Gaps and flushes are checked around the trim and the CD player is tested with a speaker-threatening track called ‘Ugly Duckling’. “Apart from the damage to the paint, this is a good car,” declares Palmer.

So only another 917 DB11s to go. Why does he do it? “This is Aston Martin’s first brand-new car in 12 years. People don’t easily buy the first year of production, so I’m doing this to inspire confidence for the consumer and say that it’s okay. It’s a hard commitment to quality.”

There’s more to it than this. “I want to instill in the workforce the idea that quality is everything. If I’m prepared to spend four hours a day, it must matter. It’s quicker to build a quality car, too. Everything I’ve learned with the Japanese is going into this, from Honda during my time at Austin Rover to Nissan,” where Palmer was chief performance officer before joining Aston. “There’s a lot of kaizen here,” he says of Aston’s continuous improvement ethic. “It doesn’t matter if you make a mistake. You just need to learn from it. I want to take away the fear factor from the British motor industry.”

Palmer explains all this as he drives the DB11 through the factory towards the so-called squeak and rattle test track. It’s designed to be driven at 5mph, apart from the 2.5mph final section, whose trapezoidal humps impose squeak-provoking twist on the body. Before that come slender transverse rails, strings of rope, a tight, uneven turning area and some pavé. This car produces no stray sounds once he smilingly removes the loose key in its centre console, so no issues here.

Palmer opens the bonnet and applies his inspection plaque. (It wouldn’t normally go on until that paint defect is rectified, he explains, but he’s doing it for our photos.) It may be only a symbol, but it’s a symbol of real effort from Palmer, demonstrating to colleagues and customers that he’s stay-behind serious about Aston Martin quality.

Source: Autocar UK

RELATED ARTICLES

Inside Three-Pointed Star's Global EV Rethink and Why the CLA Matters More Than It Seems

After years of building EVs under a separate identity, Mercedes-Benz is folding electric models back into its core brand...

Why India’s CBG Revolution is Stuck in Neutral

Seven years after a bold promise to build 5,000 plants, India’s compressed biogas sector is struggling to move past the ...

The Car that Exists Before it Exists

The car you buy today was likely built twice — once in software, once in steel. The companies that have figured out how ...

10 Dec 2016

10 Dec 2016

9409 Views

9409 Views

Ketan Thakkar

Ketan Thakkar

Arunima Pal

Arunima Pal

Anurag Chaturvedi

Anurag Chaturvedi