Toyota’s proactive steps towards zero carbon plant

TKM’s manufacturing plant at Bidadi with key contributor being optimisation of renewable energy was recognised as the ‘Model Plant’ under its ‘Zero Co2 plant’ challenge among the Toyota Asia-Pacific affiliates.

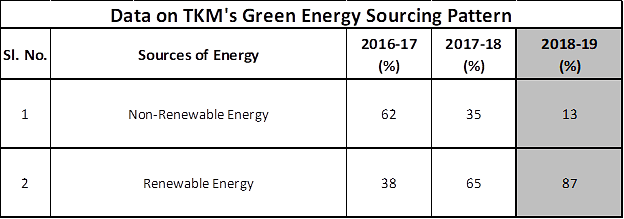

Guided by Toyota’s ‘Global Environmental Challenge’ 2050 and in line with the 'United Nations Sustainable Development Goals', till January 2019 [in FY 2018-19] - Toyota Kirloskar Motor (TKM) claims to have successfully sourced 87 percent of electricity from the renewable source of energy for its operations in Bidadi facility.

With a key focus on its energy challenge, Toyota has been swiftly moving from non-renewable to renewable sources of energy across its business operations as electricity consumption is one of the major sources of energy in the manufacturing sector. TKM has been able to prove its eco-commitment with continuous improvements in green energy sourcing trends year-on-year. It's focused on achieving harmony between its manufacturing activities and the environment based on the concept of 'a plant that optimally utilises natural resources while operating in harmony with the natural environment’, thus working towards one of the national issues of energy security.

Toyota started its journey towards greening its energy source since 2015-16 and has made substantial step-up over the years. The company has installed in-house solar power plants at rooftops and ground in its facility at Bidadi, which has a combined capacity of 8.4 MW of electricity. Toyota Kirloskar Motor has explored various possible avenues to increase its renewable energy share, including in-house solar parks, outside solar parks, open access sourcing and many more. The renewable energy sourcing has increased from 15 percent in FY 2015-16 to 65 percent in FY 2017-18. The below reference tables showcase TKM’s energy source patterns over the years, towards optimisation of renewable power usage at its plant facility:

Indian power sector being highly dependent on the coal-based thermal power plants is one of the major sources of CO2 emission. For sustainable development, there is an urgent need to adopt energy efficiency measures with renewable energy sources such as wind, solar, and others [replacing fossil fuels], being priority choices by wide varieties of manufacturing sectors.

Speaking on Toyota’s commitment to environment protection and sustainability, Masakazu Yoshimura, managing director – Toyota Kirloskar Motor said, “Business can play a significant leadership role in accelerating the transition to a lower-carbon economy, we see renewable energy to be a key component of climate action efforts. As a responsible corporate citizen, we at Toyota strongly believe in the philosophy of ‘Respect for the Planet’. Reiterating our commitment to enable greener environment, TKM sources clean energy and adopts smart manufacturing systems towards Toyota’s ultimate global mission of ‘Zero Carbon Emission”.

He further adds, “Over the years, TKM has been stringently working towards reduction of dependency on non-renewable energy resources by implementing various energy management procedures to achieve environmental sustainability. Its renewable energy strategies prioritise energy efficiency and policy advocacy, well aligning with Government’s initiatives. I am very proud to declare that during October 2018, we achieved 100 percent renewable power source for our energy requirements. Through such significant goals, TKM could effectively contribute towards emission reduction by over 51,000 tons of Co2 during first three quarters of FY 2018-19.”

In addition to these efforts, TKM has also devised strategies to reduce the Co2 emissions at its manufacturing facilities through energy ‘Consumption Reduction’ and ‘Conversion Efficiency’. Under conversion efficiency enhancement approach, TKM aims to improve the operational efficiency by transforming energy from one form to another form through continuous improvements which has been contributing effectively towards maximisation of green energy adoption at TKM’s manufacturing plant.

Additionally, through various initiatives like adoption of reverse refrigeration system, centralised control of chillers, adoption of smart ACs, TKM has been reducing a significant quantity of Co2 releases over the years. The company has also been vesting enormous efforts to reduce its energy consumptions through controlling and reducing daily energy consumption in each of the operational processes instilling stringent and systematic monitoring to track energy usages.

Recognising these efforts on reduction of emission in TKM’s manufacturing plant with key contributor being optimisation of renewable energy, TKM was recognised as a ‘Model Plant’ under its ‘Zero Co2 plant’ challenge among the Toyota Asia-Pacific affiliates.

Toyota is set to challenge the goal of zero Co2 emissions by 2050. From fuel-efficient vehicle to developing ever better eco techniques and approaches, TKM focuses on environmentally sustainable solutions in each of its business operations and every single vehicle that is manufactured in the plant facility.

Toyota recently launched the new Camry Hybrid electric vehicle. Toyota’s strong hybrid technology not only aims at creating harmony with man, nature and machine but also positions as the future of eco-mobility. The Camry Hybrid or self-charging electric vehicle is a strong hybrid and the only hybrid which is locally manufactured at Toyota Kirloskar Motor’s second plant located at Bidadi. Toyota celebrates global cumulative hybrid sales of more than 12 million with a reduction of 94 million tons of CO2.

RELATED ARTICLES

Why India’s CBG Revolution is Stuck in Neutral

Seven years after a bold promise to build 5,000 plants, India’s compressed biogas sector is struggling to move past the ...

The Car that Exists Before it Exists

The car you buy today was likely built twice — once in software, once in steel. The companies that have figured out how ...

Can Isobutanol Solve Diesel’s Dirty Emissions Secret?

As the global automotive industry faces a green ultimatum for heavy-duty transport, isobutanol emerges as a high-potenti...

By Autocar Professional Bureau

By Autocar Professional Bureau

25 Mar 2019

25 Mar 2019

16911 Views

16911 Views

Arunima Pal

Arunima Pal

Anurag Chaturvedi

Anurag Chaturvedi