Tech talk: Why aluminium chassis makes good sense for EVs

With EVs needing increasingly heavy batteries to provide longer ranges, lightweight construction has never been more important to car makers.

Try going for a run, or even a couple of trips upstairs, wearing a 30kg backpack and it soon becomes obvious how much hard work it takes to lug that extra weight around.

Lightweight technology is even more pressing with the rise of EVs, as the multiple-award-winning Jaguar I-Pace demonstrates. It makes no sense to build an EV with a heavier steel chassis and body and then compensate for that weight with a bigger, heavier battery.

As far as fuel consumption goes, a lighter car needs less energy to move it: it’s as simple as that. Pushing a classic Mini on your own is easy but moving a full-sized SUV solo is anything but. So manufacturers are always looking to reduce weight or at least reduce the weight spiral, mainly by using lightweight steel and aluminium alloy in the body construction. Although far cheaper than carbonfibre, aluminium construction is expensive, partly because of the material itself and partly because of the construction methods. That’s why it only appears to any great extent in premium cars.

Steel is a relatively easy material to work with and panels can be pressed and folded with crisp, sharp edges. Aluminium panels are less amenable to sharp folds, and if the radii on a swage line are too small or a shape too intricate, the material can crack. Designers and engineers have to work more closely to achieve the shapes designers want.

Joining the stuff together gets trickier as well. Whereas manufacturers have been joining steel for decades using MIG or spot welding, bolting and, to a lesser extent, riveting, some different methods are needed for aluminium. A favourite for joining panels is bonding (gluing) and riveting using self-piercing rivets. A conventional rivet is pushed through a drilled hole and bashed over, but self-piercing rivets push through the first layer of aluminium without drilling and splay out into a second layer but without piercing it. In cross-section, it resembles a wisdom tooth with those large roots and once in, like the tooth, it doesn’t want to come out.

A tricky aspect of mixing steel and aluminium is the possible effect of galvanic corrosion between the steel and aluminium, a battle that the aluminium generally loses and causes it to fall apart. That means adding some protection apart from the glue and, for example, Volkswagen uses a purpose-designed lacquer on the two surfaces to keep them apart by a whisker – even though they’re joined.

Reducing the weight comes not just from the intrinsic weight of the material but also from its strength. Modern aluminium alloy body structures use a mix of different types of alloy and using a higher-strength grade for some body panels means they can be thinner and even lighter, creating a virtuous circle.

Don’t ever expect to see a car made in pure aluminium, though: it’s too soft. An aluminium alloy contains a trace of other materials such as silicon and magnesium. It’s clever stuff and why, in some respects, car making today is more about what happens in a chemistry laboratory and a little less about spannering.

A balanced diet

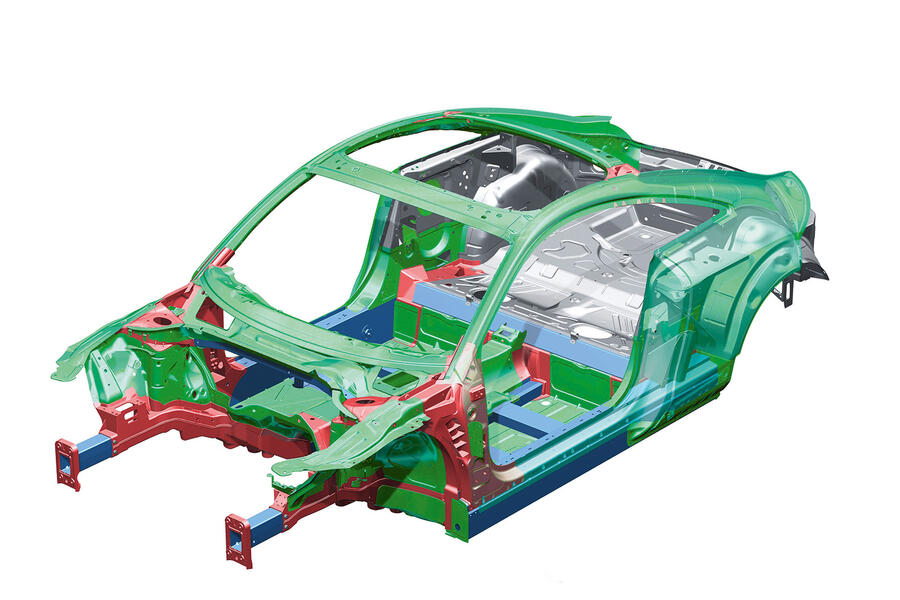

It’s not all about overall weight: where materials are used sometimes has a bearing on weight distribution, too. The Audi TT retains some steel (coloured grey) at the rear to maintain enough weight on the front-engined car over the back wheels. The rest is aluminium.

RELATED ARTICLES

Inside Three-Pointed Star's Global EV Rethink and Why the CLA Matters More Than It Seems

After years of building EVs under a separate identity, Mercedes-Benz is folding electric models back into its core brand...

Why India’s CBG Revolution is Stuck in Neutral

Seven years after a bold promise to build 5,000 plants, India’s compressed biogas sector is struggling to move past the ...

The Car that Exists Before it Exists

The car you buy today was likely built twice — once in software, once in steel. The companies that have figured out how ...

27 May 2019

27 May 2019

18135 Views

18135 Views

Ketan Thakkar

Ketan Thakkar

Arunima Pal

Arunima Pal

Anurag Chaturvedi

Anurag Chaturvedi