Safer toys for India: Behind the scenes at Centy Toys’ factory

Autocar India explores the safety norms that govern the making of scale model cars at Centy Toys.

There’s plenty to choose from when it comes to international scale models, but if you are looking for a manufacturer of Indian centric miniature vehicles, homegrown brand Centy Toys is what you should zero in on. The Delhi-based toy brand makes scale models of popular Indian transport vehicles and while they are moulded in plastic, the attention to detail and finish is really very good, to the point where even serious scale model collectors have a few in their collection. Till date the brand has sold over 43 million units since it began in 1990.

So we really had to go and see for ourselves how and where these little beauties are made.

The factory is situated at Bawana near New Delhi and at first glance comes off as a cottage scale industry setup. However, the Government of India has laid out stringent testing procedures and quality standards under the Bureau of Indian standards for toys and is very firm on their implementation, especially to keep out a flood of poorly built Chinese toys. Thus, look closer and you’ll see the brands assembly is controlled very carefully with a lot of testing involved.

Before handing over samples to the official government testing agency, Centy Toys gets its products tested in house and at some individual testing agencies.

This testing is to authenticate the compatibility of the toys not only with Indian safety standards (IS 9873 - Part 1, 3, 6 and 9) but also with international benchmarks such as EN71 (European Standard), ASTM-F963 (American Standard), and AUS/NZ (Australian and New Zealand Standard).

Centy Toys’ testing procedures adhere to the Bureau of Indian Standards (BIS) guidelines, specifically IS9873 (Part 1) for Mechanical Pull Back Toys and IS15644 (Part 1) for electronic toys.

Drop test

The first thing we witness is the drop test where the specimen is dropped from a specific height (100 cm) to a flat floor. Yes, collectors will not drop these but the many children that do buy them will do so and repeatedly. The drop test thus checks to see if there is any damage to the vehicle surface, or if any part breaks or falls apart. All of the findings are recorded and documented for improvements, if needed.

Sharp edge test

The testing specimen is tested for any sharp edges that are left in the production process which could potentially harm a child or anyone handling the toy. And no, an operator does not lend his or her hand as the implement but a device called Sharp Edge Tester is used to check for sharp edges. The edges of the toy are pushed against a rotating rod with a tape wrapped over it. If the tape gets torn, then the edge is identified as a cutting surface.

Sharp point test

The sharp point test involves assessing potential hazards from sharp points. An impressionable tool is used and pressed against potential sharp points with a specified amount of force. If it creates an indent, the point is determined to be a sharp point and thus unsafe.

Compression test

A compression test evaluates a toy’s structural integrity by applying a set force to assess its resistance to deformation and breakage. After all, children will be children. The compression test is thus vital, guaranteeing toys are durable, safe, and able to endure the rigours of child’s play.

Tension test

The tension test evaluates whether small parts snap off the main body of the toy when tension is applied, as these small parts could be a potential choking hazard. In the toy testing lab, a technician pulls the toy with a force equivalent to a child’s strength. If the test fails, the toy part design is changed and strengthened to bear that specified load.

Torque test

This is to determine whether components of toys can be removed by a certain torque force. A torque-measuring device is used in conjunction with a torque clamp to record the applied force. Any projection, part or assembly of a toy that a child can grasp with at least the thumb and forefinger or the teeth - yes kids love to put things in their mouth - will be subject to the torque test.

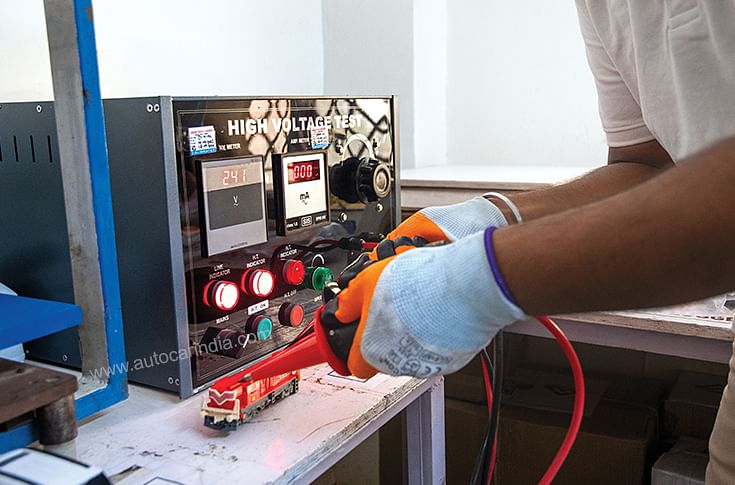

Hi voltage test

This test is for battery operated toys only and involves subjecting the toy to a higher-than-normal voltage to assess its resistance to electrical stress and to verify that it can withstand abnormal conditions without posing a risk of electric shock or other hazards. The purpose is to identify any potential weaknesses or vulnerabilities in the toy’s electrical components and insulation.

Testing times

These tests are essential to not only meet local norms but the certification obtained also helps Centy Toys sell their products in many international markets without facing safety related legal hurdles.

Sarabjeet Singh, CEO, Centy Toys

Sarabjeet Singh, CEO, Centy Toys

Its quite an eye-opener seeing the amount of tests these toys go through, “These toys have been through more safety tests than their real-life counterparts,” quips Sarabjeet Singh, CEO of Centy Toys.

The company employs around 150 staff that includes 70 women, and is already setting up a second and a much bigger unit in Khushkhera (Rajasthan) which will be operational by June 2024.

Much like a real-life automotive manufacturer, Centy Toys has set up their own supplier park around the Bawana facility. Companies that supply raw material granules and other products are located very close to the main facility which helps in quicker procurement and faster production.

While most of the design parts are unique to each model, the wheels and the pull back mechanisms are similar again to platform and component sharing in a real automobile.

The material used is ABS Plastic and the final product weighs around 120 gms when ready for dispatch to the market. Singh says Centy Toys is slowly increasing its footprint in markets like Australia and Canada and the brand is cleverly targeting sales in overseas Indian stores cashing in on the sentiment the Indian diaspora has for seeing vehicles from back home.

During the time of our visit, the team was busy putting together unit after unit of the popular ‘Queen 70’ which is basically a slightly different looking scale model of our beloved Premier Padmini.

Given their finish and level of detail, these have been quite the rage online with collectors and enthusiasts, and yes, I gladly took back a few for our office staff too.

Photography: Kuldeep Chaudhari

RELATED ARTICLES

Policy, Protectionism and Pressure: Inside India’s Construction Equipment Downturn

India’s construction equipment sector faces a tough battle as it takes on cheaper imports from China and a slowdown in g...

Beyond Cars: VinFast's Full-spectrum EV Push in India

With $2 billion committed, VinFast is constructing an integrated play spanning cars, scooters, buses, ride-hailing and c...

A Breather for Hero

A combination of policy tailwinds, new products and Honda’s cautious approach on EVs put a stop to the constant encroach...

29 Mar 2024

29 Mar 2024

6447 Views

6447 Views

Shahkar Abidi

Shahkar Abidi

Kiran Murali

Kiran Murali