Continental targets India with new-age vehicle tech

At the recent Continental Tech Day in New Delhi, German Tier 1 supplier displayed its range of active and passive safety systems, hybrid-electric drives and a gamut of India-specific BS VI products to be supplied to two-wheeler OEMs in India from Q3 of this fiscal.

As megatrends sweep the automotive industry the worldover, it is imminent for technology majors to be taking up a crucial role and enabling the shift towards a sustainable future.

German Tier 1 major Continental has its role defined in such a dynamic environment where it aims to cater to the challenging needs of the auto industry by implementing what it has already learnt in more developed markets abroad and also conceptualising technologies which will be tailor-made to suit India's unique requirements.

At the 'Continental Tech Day 2019', held in New Delhi on June 11-12, Continental demonstrated what all it has on offer for the Indian market as it sees India aligning to the global regime of road and pedestrian safety, and cleaner emissions. Let's have a closer look into the future.

ESC and EPB

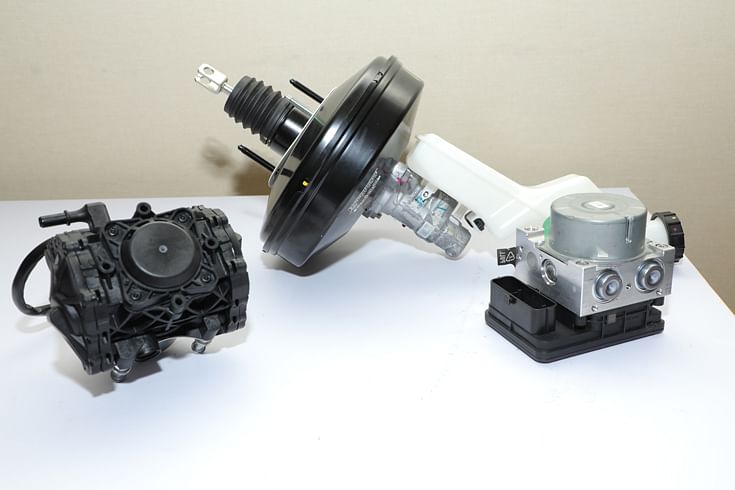

With hydraulic braking system being one of its core and established businesses in India, the company displayed its new range of brake boosters and calipers along with electronic parking brake (EPB) systems for both drum- and disc-brake setups.

The innovative MK C1one-box ESC unit integrates the vacuum booster, ESC module and electronic vacuum pump into one compact component.

While EPB is a relatively newer concept for the Indian market, the company is eyeing its increasing adoption once when electronic stability control (ESC) becomes a mandatory requirement from 2022-23, as the motor driving unit (MDU) in the current EPB form is compatible to only get inputs from the ESC module.

The brake boosters ranged from 7-10 inches in diameter with an integrated tandem master cylinder to develop brake pressures between 0.5 to 0.9mBar, with Continental also having developed a new electronic vacuum pump to generate brake pressure in case of an EV, hybrid or SCV application, where the pressure generated from a conventional booster might not be sufficient considering the low power of the engine.

Also on display were the MK100 ABS, MK 100 ESC and the MK 100 ESC Hybrid Plus units. Where an ABS module takes care of the linear dynamics of a vehicle, ESC comes into play at the lateral dynamics part to avoid a rollover. The hybrid plus variant integrates regenerative braking to also become suitable for hybrids and mild-hybrid vehicles.

The biggest innovation at the vehicle dynamics booth, however, was the MK C1, a next-generation one-box ESC unit. The module works on a brake-by-wire phenomenon and utilises an electric motor to build pressure in the hydraulic fluid line. Continental says that this is already gaining popularity in Europe, Japan and the US. The Alfa Romeo Giulia is the first model to be fitted with this new-age system.

Passive safety and sensorics

As India adopts new stringent norms of mandatory airbags and seatbelt warning systems, Continental showcased its airbag control units (ACUs) which it has localised at its Bangalore plant. It has also ramped up capacity for wheel speed sensors for ABS and ESC systems to now be capable of a million annual units at each of the 10 production lines it has installed, starting way back in 2011. Demand has also increased for the satellite sensors for airbag deployment – acceleration sensors at the front bumper and side pressure sensors to gauge side impact.

The company also displayed the intelligent battery sensor (IBS) which is a requirement in a vehicle equipped with a start-stop system in order to continuously monitor the state of health, charge and the state of functionality so that the car doesn't shut off if there's not enough charge in the battery to crank again. The IBS sees high adoption rate in the US and Japan where hybrid cars form a major chunk of these markets.

ADAS

On demonstration was an ADAS and autonomous emergency brake (AEB) system fitted into a Maruti Suzuki Ertiga automatic. The car was equipped with an MFL, which is an integrated multi-functional LiDAR and camera module. The system has a short-range LiDAR sensor (detection range up to 20 metres) and four external cameras (up to 40 metres vision range) - one at the front and rear and two on the ORVMs each. A go in the Ertiga gave a first-hand experience of an AEB system.

AEB system first alerts driver about a forward collision possibility, applies brakes partially and then fully engages them to bring the vehicle to a complete halt within 0.4 metres of the target.

The combined LiDAR-camera system monitors objects on the road and gives the fused data to the system ECU to analyse. An emergency brake assist (EBA) module first takes the fused objects and calculates the relative distance and speed from the 'target' vehicle or pedestrian who could be walking longitudinally in the vehicle's trajectory. The system first gives an audio warning to the driver indicating that the vehicle in front is approaching closer. On no response, the system will first pre-fill the braking system by eliminating any air from the hydraulic lines so that it is ready to deploy even if the driver gets attentive at the last moment, and in case of no driver input yet, the next automated step by the AEB system will be partial braking with the last resort being full brake application.

The system can create G-forces of up to 1G in case of the car braking itself and coming to a complete halt from a speed of up to 40kph in an attempt to prevent hitting the target by 0.4 metre. Even still if the vehicle hits the target with up to 5kph impact velocity in slippery conditions, the vehicle still passes with a 5-star rating from Euro NCAP.

Hybrid-electric drivetrain

With a 450V third-generation electric motor on display, Continental showcased an integrated electric drivetrain ready for application in passenger vehicles for power requirements of up to 120-150kW and 275Nm.

Also, with a 48V battery starter generator (BSG) on offer, the company is ready for 48V mild-hybrid applications for compensatory power requirements of up to 14kW and 15Nm with an integrated starter generator's torque assist function and offer a 15 percent increment in fuel efficiency.

A unique application of the 48V battery starter generator (BSG) as a standalone electric motor in an electric scooter prototype. Continental will be ready with the technology by the end of 2019.

Continental interestingly demonstrated an electric two-wheeler application with the 48V e-motor as a standalone drivetrain in a European model Vespa scooter.

New solenoid BS VI fuel pump

As India sets to move closer towards a bigger target of achieving BS VI emission norms across all vehicle segments by April 2020, Continental is also helping two-wheeler OEMs in their accord. The company has developed BS VI EFI (electronic fuel-injection) systems for two-wheelers, both for low-end (below 150cc) and high-end applications.

With its specially designed 'M4' throttle body module, it has integrated the MAP sensors, intake air temperature sensor, throttle position sensor and the idle air control valve (digital linear actuator) into one compact body. This product does away with multiple connectors and wiring of each of the sensors, and similarly with their mounting grommets on the vehicle body, thus implying cost savings. The M4 has been developed especially for the China and India markets.

Continental’s EFI system range for BS VI application includes integrated throttle body, solenoid-based fuel pumps, fuel injectors and ECUs.

The company has also developed a solenoid-based fuel pump (Deca 10) which reduces the size of the pump and offers demand-based fuel supply. Instead of running continuously, it only pumps fuel into the fuel lines at selective instances, thus bringing about reduced fuel consumption, wastage and at the same time, also enhancing the life of the product.

Continental says that it is currently engaged with OEMs to supply these products and while SOP is slated for Q3 of FY2020, trial runs at its Pune plant have begun. The company is eyeing between 500,000 to 700,000 annual volumes of the EFI products.

Also read: Volkswagen invests in Ethiopian automotive industry

RELATED ARTICLES

RSB Group Prepares for Hyper-Growth: New Markets, Tech and Mission ₹10,000 Cr

From a small workshop in Jamshedpur to an engineering group with global reach, RSB Transmissions is preparing for its mo...

Beyond Helmets: NeoKavach Wants to Make Rider Airbags India’s Next Safety Habit

As premium motorcycles proliferate and riding culture evolves, an Indo-French venture is betting that wearable airbags, ...

Inside Mahindra Last Mile Mobility’s Rs 500 Crore Modular Platform Strategy

Mahindra Last Mile Mobility has launched the UDO, an electric three-wheeler built on a new Rs 500-crore modular platform...

15 Jun 2019

15 Jun 2019

24719 Views

24719 Views

Darshan Nakhwa

Darshan Nakhwa

Shahkar Abidi

Shahkar Abidi