Building the Dragon

Like many modern engines, the Dragon has a crank offset by 10mm to help reduce piston slap and friction.

Ford's new 123hp, 1.5 Dragon petrol engine will power the refreshed EcoSport compact SUV which is to be launched on November 9.

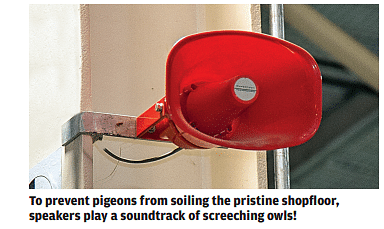

The first surprise is the ‘clean room’- like atmosphere. This is a factory, and so it’s natural to expect some grease and grime. But, as is the norm today, the entry to this modern engine shop is via a ‘dust-tunnel’, the type normally associated with a paint shop. Walking along the long chrome tunnel, with hundreds of vents blowing high pressure air at me from all directions, is quite disorienting. And then, when I finally exit the maelstrom, I hear something that creeps me out completely – shrill blood-curdling screams and screeches.

Is someone rehearsing for a role in a Ramsay Brothers’ horror movie? Of course they aren’t – these are angry birds: birds of prey. And the screeching is so frenzied, I instinctively look up as we step onto the factory floor, half-expecting to be divebombed by an eagle. The guys from Ford India start chuckling; “We play the sounds of screeching owls to get rid of the pigeons,” says one.

HIGH TECH, LOW COST

But let’s forget about clean rooms and owls for I’ve come to meet the Dragon. So, after a quick safety briefing, we go straight to the line. Now Ford’s new engine will take over from the current 1.5 petrol, so it has to be potent as well as affordable. And, truth be told, there are a lot of costsaving measures worked into this engine.

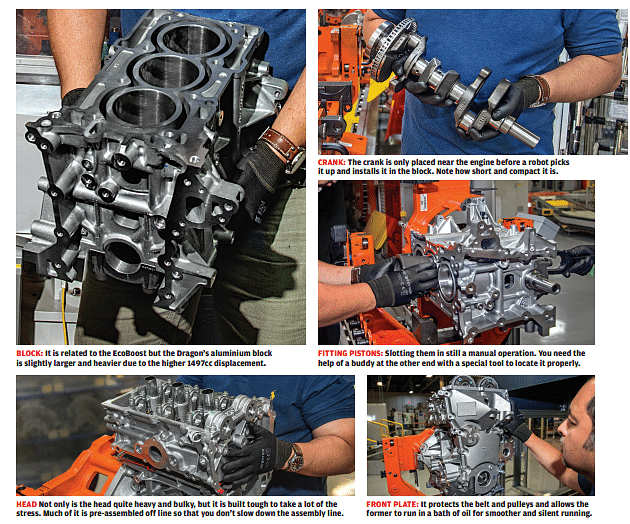

There’s no turbo, no direct injection and a few other high-tech bits have been deleted too. But I get something of a shock when I come face to face with the aluminium block. The quality of the machining and detailing are right up there with some of the best engines I’ve seen in this class. I then walk over and pick up the crankshaft and the ‘cracked’ or ‘broached’ pistons, and am even more surprised.

This engine is a distant relation of the EcoBoost, and since it’s a three-pot, I lift the block, just to gauge how heavy it is. It is 500cc larger and so is a bit bigger, but yeah, you could take this 12 or 13kg lump of aluminium as hand luggage, just as a Ford engineer did in the US with the EcoBoost block.

Ford engine assembly at the Sanand plant is done partly by robot and partly by hand and, as is the norm, there are digital and electronic checks and measures at every stage. So, getting stuck in, gloves on, is relatively stress-free.

The engine I’m assembling is first placed on its side and I click the main bearing caps in place. It’s more difficult than it looks, as you have to align everything perfectly, and press hard to get that telltale ‘click’. But each part fits just right and it would; remember Ford pioneered interchangeability of parts and mass production.

Soon after the block is picked up by a robot, the cylinder bores are lubricated, and we catch up with the bottom half of the engine further down the line where I have to manually slot the pistons in. Like many modern engines, the Dragon has a crank offset by 10mm to help reduce piston slap and friction. When we stand this unusually tall engine up, I can sort of tell. What’s fascinating to see is that this engine also has extra reinforcement in the shape of a ‘ladder frame’ that helps reduce noise vibration and harshness. And that’s what goes on next.

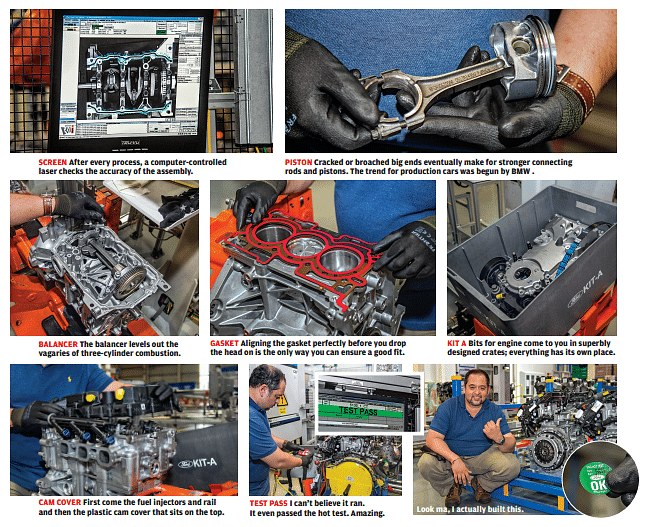

Then the engine is flipped upside-down again and the balancer shaft installed. Ford managed to tune out the vibrations in the smaller-capacity EcoBoost without a balancer, but this larger 1.5 needs one. Each power stroke is more potent and disruptive, and since this engine isn’t turbocharged and uses lower pressure port injection instead of direct injection, the components are much lighter. Then, I put in the surprisingly tiny variable displacement oil pump that also improves efficiency, and the oil pan.

BACK TO THE TOP

Bottom end done, we move to work on the gasket and head. Like some other modern engines, Honda in particular, this one has an integrated exhaust manifold. This means no joints, no fasteners, and one job less for me. Then the twin camshafts go in, all 12 bolts driven in at the same time by a machine, but I have the difficult job of aligning the two cams. This requires a fair amount of dexterity as I have to align the twin arrows on the cam gear wheels, while holding the cam steady with a spanner. I’m only sure I’ve nailed it when an ‘OK’ pops up on the screen; which, let me tell you, is a big relief.

Dual variable cams aren’t something Ford pioneered, but no mention of them can be made without remembering Ford’s legendary Formula 1 engine – the DFV or Double Four Valve. This V8 ran its first F1 race exactly 50 years ago, and powered an incredible 155 F1 cars to victory before its eventual retirement.

SPARK, PLUG AND BELT

Then comes the most difficult part – linking all the moving parts together. Still, this belt is easier to thread around the various teeth than most chaindrive systems. Though Ford’s minders help, it slots in after only a bit of push and pull. “What’s important to remember is that both cams can be phased by the ECU, and this means the engine can be optimsed for both low-and high-speed operations,” says the man from Ford. But I’m more concerned by the quality of my assembly.

After this, I bolt on the integrated front cover that protects the belt and allows it to run through an oil bath for greater smoothness and efficiency. How often do you need to change belts? Ford says 200,000 kilometres. Wow!

Today’s engines also have a lot more plastic. So, after slotting in the fuel rail, cam cover and plastic inlet, I push in the coil and plug combos. Then it’s time to click all the connectors and make sure everything fits just right. As the engine is taken into the test bench, I’m a wreck – I’m sure I’ve messed up somewhere. Were the plugs wired correctly? Did I forget to tighten something? What happened to piston number four? Wait, this is a three-cylinder engine.

Ford did have three engineers watching me and checking everything I did but they don’t want to take any chances. Can you blame them? Then, a miracle – the engine fires, and I even gets an ‘OK’ on the screen.

The Dragon or Ti-VCT, as Ford officially calls it, will eventually be exported to 50 markets globally from Sanand. Deliveries have begun and the engine is proving to be quite popular as it is a massive 10 percent more efficient than the one it replaces. What should also give Ford an edge in India is that 80 percent of the parts are locally sourced. But what’s it like to drive? In a word, impressive. Its 123hp output is just 2hp shy of the 1.0 EcoBoost's, and though the turbocharged motor's hit of torque is missing, what you get is a smooth, consistent surge of power. It's not weak at low revs and there's no sudden spike in power at high revs, as you might find in similarly sized naturally aspirated motors. This flexible powerband makes for easy driving in any and all conditions.

(This article was first published in the November 1, 2017 print edition of Autocar Professional)

RELATED ARTICLES

Beyond Cars: VinFast's Full-spectrum EV Push in India

With $2 billion committed, VinFast is constructing an integrated play spanning cars, scooters, buses, ride-hailing and c...

A Breather for Hero

A combination of policy tailwinds, new products and Honda’s cautious approach on EVs put a stop to the constant encroach...

Renault India's Quiet Fixer

As the head of Renault India, Francisco Hidalgo Marques faces his biggest challenge yet.

27 Nov 2017

27 Nov 2017

18413 Views

18413 Views

Kiran Murali

Kiran Murali