Auto R&D drives Vector Informatik’s growth

As vehicles get more technology intensive, there is higher demand for R&D from OEMs and suppliers which is where software tools provider Vector Informatik plugs in.

Germany’s Vector Informatik is very bullish on its India operations. It has many reasons to be, primary among being the burgeoning business in the Indian automotive R&D sector for its software and hardware tools.

As vehicles turn more technology intensive, automakers and their component suppliers are increasingly banking on R&D for testing, calibration and diagnostic tools to design and develop new products. Vector has both hardware and software solutions to help automobile engineers to design and develop automotive products.

“Name any automotive player, they are our customers,” says a confident Brahmanand Patil, managing director of the Pune-based Vector Informatik India.

According to Patil, the company provides OEMs and suppliers a professional and open platform of tools, software components and services for developing embedded systems. These help automakers conduct testing, calibration and measurement activities in automotive R&D. They include CANoe, CANalyzer, vTESTcenter, vTESTstudio and VT System which are used for ECU testing while other tools like CANape, VX1000, CDMStudio and vADASdeveloper are used for ECU calibration. The company’s diagnostics tools include CANdelaStudio, Indigo and vFlash.

Patil says, “Since Vector is one of the first premium members of the AUTOSAR consortium, we can offer a complete solution: tools, basic software, engineering services, on-site support and training classes.”

Vector solutions are currently used by a number of leading OEMs and Tier 1 suppliers in India including Mercedes-Benz, Tata Motors, Bosch, Continental and Delphi. Even software majors like Infosys and Wipro use them for their automotive R&D programmes, he adds.

In May this year, Vector had organised its first India conference in Bangalore, aimed at bringing together automakers, Tier 1 suppliers and software service providers on a common platform to discuss automotive electronics, software and technologies like driver assistance, Ethernet, AUTOSAR and safety.

Alexander Aydt, principal product management engineer ADAS, Vector Informatik GmbH, said the company’s vADASdeveloper is used in the area of Advance Driver Assistance System (ADAS).

He said vADASdeveloper provides an infrastructure for developing algorithms for ADAS and automated driving. The tool reduces workload in developing sensor data fusion applications. The runtime environment acquires sensor data, logs it and can replay the data for stimulation. Key highlights of the software is that it accelerates the development process, increases system quality and gives the ECU developer a high degree of flexibility.

Another presentation by Ashish Wadhwa, divisional manager, E&E, Tata Motors, highlighted the Vector tools with PREEvision for ECUs fitted in Tata vehicles. PREEvision, the development platform for the entire E/E product development process, integrates design, evaluation, optimisation and documentation of E/E architecture in a single tool. Vector Informatik says PREEvision supports developers throughout the E/E development process from requirements engineering, through design to testing. Mercedes-Benz is among the global automakers to use it.

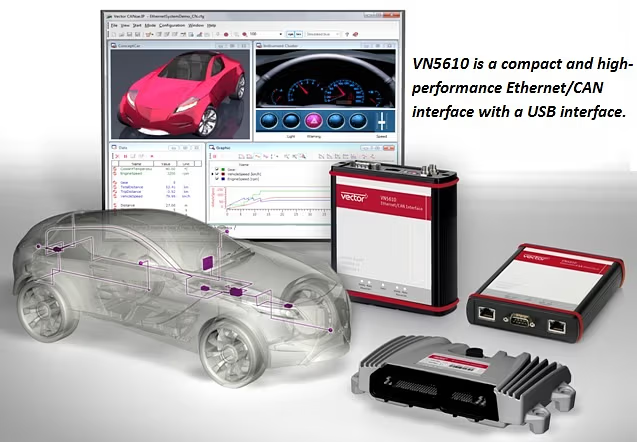

Many OEMs and their suppliers are already implementing Ethernet-based electronic networking. One of Vector’s solutions — VN5610 — is a compact, high-performance Ethernet/CAN interface with a USB interface which provides access to Ethernet-based systems and also supports the BroadR-Reach standard. .

While the VT System is a high-performance modular test system for comprehensive ECU testing, CANoe is the associated test automation software for individual ECUs and networks and flexible test hardware for the developer’s workstation. Its functions include switching various signal paths, simulation of loads and sensors, measurement of ECU signals, and stimulation of ECU inputs.

There’s also Vector Controller 121, a universal controller which can be used as a gateway of I/O controller, and claimed to be ideal for speedy development of prototypes and for use in small production runs in motor vehicles.

INTERVIEW with Brahmanand Patil, managing director, Vector Informatik India

Automotive R&D activity is seeing rapid growth in India. How do you see this trend going forward?

India is known for its skill in information technology and some companies like Bosch, Continental and Delphi have taken first-mover advantage of this. Now many Tier 1s and technology companies are using this available talent pool, working for developed markets from India. What’s more, global OEMs like Mercedes-Benz, Renault-Nissan and Ford are also coming to India not just to sell their products but also to conduct R&D activities. That is the big change that has taken place in recent years.

What is India’s standing in Vector Informatik’s global scheme of things?

From the global company perspective, India is a very important market for Vector. Even before setting up a subsidiary in India, Vector products were being used here. However, now we are closer to our customers in India. Our tools are being used by many engineers attached to global OEMs and Tier 1s worldwide and many of them have now set up their shops in India.

We have operations in 12 countries. Outside the US, Europe and Japan, China and India have good potential for Vector business. Headquartered in Pune, Vector India also has a support centre in Bangalore. The Indian subsidiary of Vector Informatik is equipped with 20 high-level staff.

How do you see government regulations driving your growth in India?

Several new rules and regulations are being imposed in areas like emissions and safety. This will increase electronics content in vehicles and force the OEMs and Tier 1s to engage in more R&D activity. That, in turn, will drive the growth of our business in the country.

This article was first published in Autocar Professional's July 1, Indo-German special

RELATED ARTICLES

RSB Group Prepares for Hyper-Growth: New Markets, Tech and Mission ₹10,000 Cr

From a small workshop in Jamshedpur to an engineering group with global reach, RSB Transmissions is preparing for its mo...

Beyond Helmets: NeoKavach Wants to Make Rider Airbags India’s Next Safety Habit

As premium motorcycles proliferate and riding culture evolves, an Indo-French venture is betting that wearable airbags, ...

Inside Mahindra Last Mile Mobility’s Rs 500 Crore Modular Platform Strategy

Mahindra Last Mile Mobility has launched the UDO, an electric three-wheeler built on a new Rs 500-crore modular platform...

By Jaishankar Jayaramiah

By Jaishankar Jayaramiah

17 Jul 2016

17 Jul 2016

19251 Views

19251 Views

Darshan Nakhwa

Darshan Nakhwa

Shahkar Abidi

Shahkar Abidi