How Ashok Leyland developed the Guru

The commercial vehicle segment is no different to this approach even as market dynamics are changing fast with diverse transportation needs.

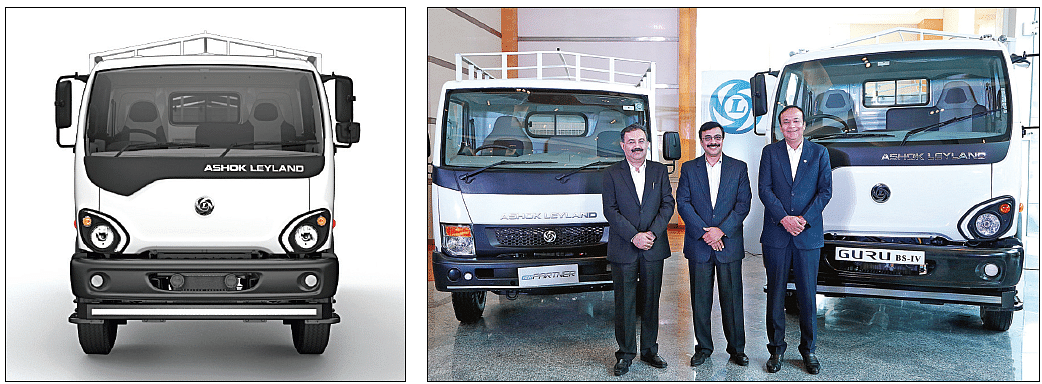

The Guru, launched this January, was born of a need to fill a gap in Ashok Leyland’s intermediate commercial vehicle portfolio. Developed in a scant 18 months at a frugal project cost of Rs 30 crore and replete with innovations, the move seems to have paid off since the Guru is seeing growing traction in the market.

Constant product development or a new-product factory has become the order of the day if a company has to claim leadership or maintain growth in today’s highly competitive market environment. Vehicle manufacturers, and the entire product development ecosystem at their command strive to develop a winning product. If a product clicks with buyers, sizeable gains – both in sales and market share – are to be had and this also keeps the competition worried.

The commercial vehicle segment is no different to this approach even as market dynamics are changing fast with diverse transportation needs. Ashok Leyland, the second largest commercial vehicle maker in India, which posted sales of 25,221 units in Q1 FY2018 (-12.80%), is aggressively targeting higher market share by introducing a slew of new products and, importantly, filling gaps in its portfolio.

Backed by a strong product strategy, the Chennai-based company has maintained an over 30 percent market share in the above 16-tonne segment. Yet the manufacturer finds itself lagging behind in the vital intermediate commercial vehicle (ICV) segment due to an inadequate presence in the segment. While the ICV segment has seen some brisk growth, till 2014, Ashok Leyland had only a single product – the Ecomet – in this segment. Two years ago, it rolled out the Boss targeted at the premium end of the segment.

Recognising the high growth potential of the ICV segment due to the emergence of the hub-and-spoke transport model, the company launched the Guru in January 2017. The new product is part of a well-planned, new product strategy to double market share in the ICV category which sees nearly 50,000 units sales annually in the domestic market (split between Tata Motors and VE Commercial Vehicles and their key ICV products).

GENESIS OF GURU AS AN INTERMEDIATE CV

Speaking to Autocar Professional on the development programme of the Guru, Anuj Kathuria, president, Global Truck, Ashok Leyland, says: “The ICV segment needed an insightful focus. Employing a multi-pronged approach, we developed a completely new platform, the Boss which was launched in 2013. The Boss, along with the Ecomet range of trucks, has helped us gain market share from 6-7 percent to 15 percent but the Boss was catering to the premium segment in the overall ICV segment.”

The brainstorming for a new product began as early as 2014, a good three years before the Guru was went into standard production. Kathuria and his team discovered that there were three sub-segments emerging in the ICV segment. First off is the overload segment which was catered to by its Ecomet range, followed by the premium segment addressed by the Boss. The third is basic, functional vehicles with rated load-carrying capability. This segment alone constitutes nearly 40 percent of the total ICV market where Ashok Leyland had no product till early this year.

Clearly, the company wanted a product which would address this need of the market – and a sizeable one at that given the market size – and it went out to customers to find out the key buying reasons (KBRs). “The three to four key KBRs came out from our research – kilometres per litre delivered, reliability, unladen weight, and also comfort and style as many of these vehicles are owner-driven,” elaborates Kathuria.

Once the core team got the green signal for Project Guru, a cross-functional team comprising the best people from each function was formed and tasked with a stringent timeline of 18 months beyond KBRs and a frugal approach. Work began in April 2015 and the company reached out to nearly 600 customers, drivers and mechanics across India to seek their point of view for a brand-new truck. Armed with this information, Team Guru went to the drawing board.

The mandate for the Guru was to offer everything best in class on all the key parameters. To offer top-notch fuel economy, the team mulled over the innovative idea of a three-cylinder engine against the norm of four-cylinder powerplants in the CV industry.

“While there were apprehensions as nobody in the industry uses a three-cylinder engine (for a truck of this size) and whether the customer would accept the same, we started working to deliver the same performance in terms of power, NVH, reliability and torque curve through its lifecycle,” says Kathuria.

The Guru intermediate CV is mainly used for transportation of white goods, e-commerce and refrigerated containers.

Needless to say, this was a massive challenge and developing a completely new engine ground-up was not an option due to the strict deadline. Thus, it was decided to have a three-cylinder engine with all parts common to four- and six-cylinder engines. It was an innovative approach and the first prototype was a six-cylinder engine cut into two and a version of the engine was developed.

The Guru now comes with Ashok Leyland’s H-Series three-cylinder engine, which is a first in the segment in the industry with all the desirable fuel economy norms.

The Guru’s cabin posed another challenge and the company’s internal study revealed that the body in white (BIW) takes the maximum time in any cabin development as it requires design, engineering, validation, and tooling. To conserve time, the BIW of the Boss was used but as an alternative to plastic or fibre which is expensive, all exterior parts of the cabin are done up in steel. Steel parts not only saved cost but also provided strength to the cabin in the event of an accident. Other highlights of the Guru cabin included increased driver comfort through ergonomics and also a sleeping provision for the

driver. Another customer feedback incorporated in the Guru is that instead of styled headlamps which are expensive, simple basic lights equipped with LED are used.

RELIABILITY IS KEY

In order to achieve best-in-class payload, the company examined every aggregate and component and carried out a benchmark study. As a result, the chassis frame and suspension was re-engineered to make them lighter. “Every gram of weight which was added to the vehicle was challenged as to why it was required and could not be slashed out or made in a different material. With this approach, we ended up shedding 150kg, thereby offering best-in-class payload,” says a pleased and proud Kathuria.

Ask any truck driver or fleet owner about the key parameters of owning a truck and it’s all about one major factor – reliability. Like an aircraft, a truck makes money for its owner only when it is plying without any downtime other than regular vehicle maintenance.

To ensure a high level of reliability, Ashok Leyland undertook a cumulative 1.2 million kilometres of tests and validation of every aggregate ensuring optimal uptime for the Guru. The first few prototypes were given to drivers of customers and their feedback sought, following which necessary alterations were carried out. Meanwhile, all the company’s dealers and suppliers were kept in the loop at every stage of the product development. Attention was accorded to even smaller things like a lock for the 185-litre diesel tank and battery, the bottle-holder behind the seat and the bumper of the cab placed a tad in the front for safety, all of which has been appreciated by customers.

Another departure from industry norms was the move to offer the hand brake on the right-hand side of the driver instead of the conventional left-hand side position. Explaining the rationale, Kathuria says, “The hand brake on the left comes in a way of the driver’s seat turning full flat for sleeping purposes. After receiving various driver inputs, we moved it to the right-hand side, which is a first in the industry. This helps extend the co-driver seat with the driver seat; thus, it converts into a full berth to sleep whenever the truck is not running.”

As a result of maintaining strict timelines and cost control, the Guru was successfully developed in a scant 18 months as compared to the regular product development time of 24 months and at a total product development cost of Rs 30 crore, which is considerably lower than the average norm in the industry, thanks to the frugal developmental approach employed by the company.

GROWING MARKET ACCEPTANCE

The Guru, which is manufactured at the Pantnagar plant (but can also be produced at other Ashok Leyland plants in the country) was first launched in Chennai in January, followed by phased launches. Since then, this ICV has received an encouraging market response as sales have picked up almost immediately. Some customers are repeat buyers and Kathuria is especially happy with the endorsement received from drivers across the country.

At present, with the Boss and Ecomet, Ashok Leyland has a 15 percent share in the ICV segment. Now, with the market acceptance of the Guru, the company is optimistic about more than doubling its ICV market share to 35 percent in the next couple of years.

The BS IV-compliant Guru ICV is priced in the Rs 14.35 lakh to Rs 16.72 lakh range and can cater to a wide range of applications in the 12-tonne and 13-tonne categories with different load body options. The company says it will develop more variants and offer different load body options to customers.

While it’s still early days for the Guru (which means ‘teacher’ in Hindi), what remains to be seen is whether it teaches any lessons to the competition. Watch this space.

(This article was first published in the August 1, 2017 print edition of Autocar Professional)

RELATED ARTICLES

RSB Group Prepares for Hyper-Growth: New Markets, Tech and Mission ₹10,000 Cr

From a small workshop in Jamshedpur to an engineering group with global reach, RSB Transmissions is preparing for its mo...

Beyond Helmets: NeoKavach Wants to Make Rider Airbags India’s Next Safety Habit

As premium motorcycles proliferate and riding culture evolves, an Indo-French venture is betting that wearable airbags, ...

Inside Mahindra Last Mile Mobility’s Rs 500 Crore Modular Platform Strategy

Mahindra Last Mile Mobility has launched the UDO, an electric three-wheeler built on a new Rs 500-crore modular platform...

02 Sep 2017

02 Sep 2017

23349 Views

23349 Views

Darshan Nakhwa

Darshan Nakhwa

Shahkar Abidi

Shahkar Abidi