Ford to invest $4.5 billion in EVs by 2020

The US-based automaker is adding 13 new electrified vehicles to its portfolio by 2020, when more than 40 percent of the company’s global nameplates will come in electrified versions.

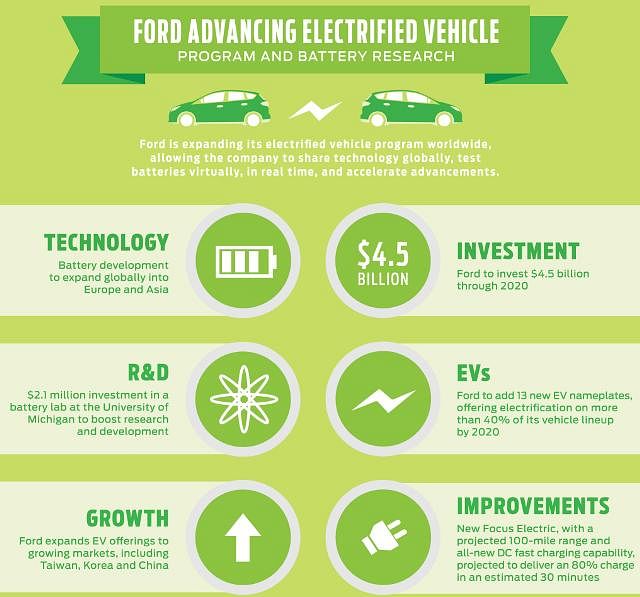

Ford has announced an investment of US$ 4.5 billion (approximately Rs 28,425 crore) in electrified vehicle solutions by 2020 apart from changing the company’s development of vehicle experiences for customers.

The US-based automaker is adding 13 new electrified vehicles to its portfolio by 2020, when more than 40 percent of the company’s global nameplates will come in electrified versions. This represents Ford’s largest-ever electrified vehicle investment in a five-year period.

On the way next year is a new Focus Electric, which features all-new DC fast-charge capability delivering an 80 percent charge in an estimated 30 minutes and a projected 100‑mile range (according to US standards) – an estimated two hours faster than today’s Focus Electric.

The new Focus Electric, which starts production late next year, will provide European and North American customers with ahost of new features such as SmartGauge with EcoGuide LCD Instrument Cluster, Brake Coach and Fun-to-drive character.

Ford says its shift to add electrified vehicle solutions addresses global trends calling for cleaner, more efficient vehicles.

At the same time, the company is expanding its electrified vehicle research and development programme in Europe and Asia this year, creating a ‘hub and spoke’ system that allows the global team to further accelerate battery technology and take advantage of market specific opportunities.

Raj Nair, executive VP, product development and chief technical officer, Ford Motor Company, said: “The challenge going forward isn’t who provides the most technology in a vehicle but who best organizes that technology in a way that most excites and delights people. By observing consumers, we can better understand which features and strengths users truly use and value and create even better experiences for them going forward.”

In addition to traditional market research, Ford is investing in social science-based research globally, observing how consumers interact with vehicles and gaining new insights into the cognitive, social, cultural, technological and economic nuances that affect product design.

“This new way of working brings together marketing, research, engineering and design in a new way to create meaningful user experiences, rather than individually developing technologies and features that need to be integrated into a final product. We are using new insights from anthropologists, sociologists, economists, journalists and designers, along with traditional business techniques, to reimagine our product development process, create new experiences and make life better for millions of people,” added Nair.

Next year, Ford is doubling the number of projects that use this type of ethnographic research versus this year.

The team of social scientists already has spent months exploring topics such as the future of luxury transport, how people form relationships with their cars and the role of trucks in the American heartland.

“As both an auto and a mobility company, we at Ford are going further than just designing the product to move people from point A to point B,” Nair said. “We are considering the way customers interact with our vehicles as a unified experience, looking for ways to excite and delight customers and make their lives better.”

Accelerated battery R&D

The global expansion of Ford’s electric vehicle R&D programme allows the company’s Electrified Powertrain Engineering teams to share data in real time and to develop new technology faster while reducing the need for costly prototypes.

The automaker is further expanding in Europe and China to accelerate battery technology research and development for new markets. By using an innovative hardware and software systems called HIL, or Hardware in a Loop, the global team can test battery technology and control system hardware in a virtual environment to simulate how batteries and control modules would behave in different – often punishing – environments in any part of the world.

“Batteries are the life force of any electric vehicle, and we have been committed to growing our leadership in battery research and development for more than 15 years,” said Kevin Layden, director, Ford Electrification Programs.

RELATED ARTICLES

Isuzu unveils D-Max EV at 2025 Commercial Vehicle Show

Revealed at the 2025 Commercial Vehicle Show in Birmingham, the Isuzu -Max EV is the first fully electric commercial pic...

Hyundai unveils next−gen highly efficient hybrid system

The next-gen hybrid system is claimed to offer 45% better fuel efficiency and 19% more power compared with ICE powertrai...

Horse Powertrain reveals hybrid conversion for electric cars

Engine-making joint venture of Geely and the Renault Group announces new hybrid powertrain that fits into the same space...

By Autocar Professional Bureau

By Autocar Professional Bureau

11 Dec 2015

11 Dec 2015

3120 Views

3120 Views