Ford debuts world’s first mobile aero-acoustic wind tunnel

Patent-pending tunnel can produce wind speeds up to 128kph, then be broken down and reassembled in just hours at any assembly plant.

American carmaker Ford, which like most automakers, is looking to make quieter vehicles, has developed a world-first mobile aero-acoustic wind tunnel to help ensure quietest cabins possible.

The fully mobile aero-acoustic wind tunnel is an innovative, patent-pending test system that allows for sources of unwanted wind noise in early production vehicles to be identified faster and solutions developed sooner. In the end, customers drive away in cars designed with a quiet interior that’s so essential to delivering a refined vehicle experience.

“This project was born from a desire to be the best when it comes to controlling and limiting the cabin noise customers are so sensitive to,” said Bill Gulker, Ford wind noise core supervisor. “And our new mobile wind tunnel saves our engineers time and increases productivity. It’s a fine example of the innovation mindset we’re trying to incorporate into everything we do.”

Ford’s new wind tunnel debuts at Flat Rock Assembly Plant in Michigan – joining a growing fleet of mobile testing facilities including three environmental evaluation chambers.

Changing the business of quiet

Full-sized aerodynamics labs, such as Ford’s main wind tunnel in Allen Park, Michigan, are outfitted with the latest in sensitive measuring and analysis equipment. These office building-sized facilities are specialized for advanced aerodynamic and aeroacoustic development work on future models, with each facility costing about $50 million. Due to the specialised instruments and cost, running time for these machines is precious.

Ford’s new mobile wind tunnel costs a fraction of what a full-sized lab costs. Because testing requires only a steady stream of highway-speed wind, many of the large and sensitive instruments of a full aero lab aren’t required. But high-tech, in-cabin sensors like the Aachen head and Noise Vision can still be used.

With an on-site wind noise facility, Ford factories can pull more sample vehicles directly from the line and test them with no delay – eliminating the time and complexity of shipping vehicles back and forth across the country.

Issues requiring assembly process refinement can be detected and resolved earlier, since everybody involved is on hand.

“Now, we’re able to detect even the most subtle noises,” said Gulker. “We can identify an area in need of improvement, have key people gather, communicate quickly, and resolve the issue without delay.”

Rethinking a wind tunnel

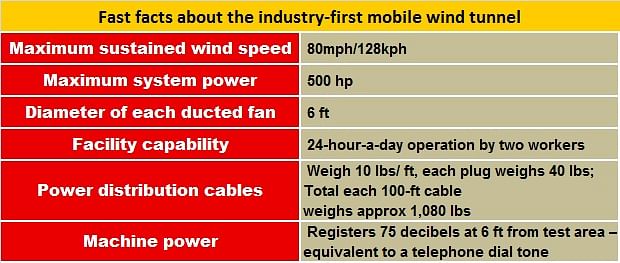

Similar in concept to a full-scale wind tunnel laboratory, the heart of the mobile facility is built inside two 53-foot shipping containers. Each includes aero-acoustic vanes and internal ducting to provide smooth, controlled airflow at the nozzle end of the machine, while two 16-bladed, six-foot-diameter ducted fans – each powered by a 250-horsepower electric motor – deliver a maximum blast of 80mph/128kph wind. A series of doors around the containers ensure the sections remain secure during transport or storage.

The machine consists of the two main containers fastened together side by side on flat, level tarmac. In between, two roll-up doors are lifted, while doors on the front and back ends are opened to create the air intake and outlet nozzle. A third, 40-foot container – housing a small office, power distribution and controls – is placed nearby, and data and power cabling are connected between the containers.

The entire operation can be broken down within a day, shipped to any Ford North American assembly facility via truck, then reassembled at the new site and ready for testing within hours.

Importantly, the ability to perform wind noise testing at its plants means Ford’s main wind tunnel in Allen Park is now freed up to concentrate on product development work for future models. This can lead to more time spent on each new vehicle, shortened development times and, ultimately, not only quieter cabins, but better fuel economy.

RELATED ARTICLES

Hyundai Mobis develops battery system with built-in fire extinguishing feature

The new system prevents heat from being transferred to adjacent cells and extinguishes a fire early by spraying an agent...

FORVIA and Smart Eye unveil in-car iris and facial biometric authentication

This world-first innovation not only enhances the user experience by enabling seamless and secure payments but also open...

Continental to discontinue tyre production at Malaysian plant

Following a business review to safeguard its competitiveness and business performance in the APAC region, where Malaysia...

By Autocar Professional Bureau

By Autocar Professional Bureau

04 May 2016

04 May 2016

5472 Views

5472 Views