Continental expands turbo manufacturing to China

Cutting-edge RAAX turbocharger, in production in Europe since 2016 for the 2L turbo petrol engine in the Audi A3, will also be built in Shanghai; to debut in Volkswagen Teramont and Tiguan SUVs

Six years after it entered the turbocharger market, technology company Continental is looking to expand its geographic footprint in this segment with the opening of its first non-European turbocharger plant at the Continental site in Jiading, a suburb of Shanghai, China.

This new facility will start producing the cutting-edge RAAX turbocharger, developed by Continental for the Volkswagen Group’s EA888 Gen.3B engine platform and in production in Europe since 2016 in the Audi A3. In the Chinese market, this 2.0-litre turbocharged petrol engine will debut in the VW Teramont SUV, followed by the VW Tiguan and other high-volume models.

Meanwhile, at Continental, preparations are already underway for the next round of expansion. This is scheduled for 2018, when production of the RAAX turbocharger – for the same Volkswagen Group engine – will begin at the Continental plant in San Luis Potosi, Mexico.

“Right from the start, our turbocharger activities have been focused on the petrol segment, and now this strategy has been vindicated by a sharp rise in demand for turbocharged petrol engines,” says Wolfgang Breuer, head of Continental’s Engine Systems business unit, which includes the Turbochargers product line. “The new Chinese facility, where our latest technologies will be built to the highest quality standards, will secure us a strong position in the world’s largest automobile market. And by next year, when production will also launch in North America, we will have manufacturing bases across all three market regions, all operating to the same high standards.”

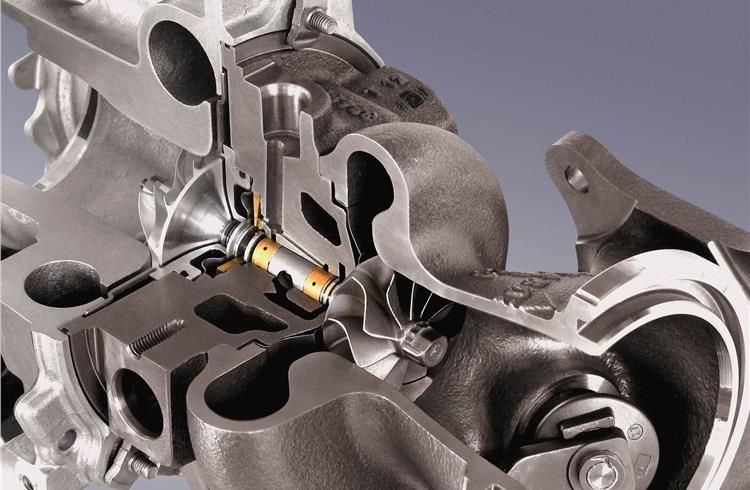

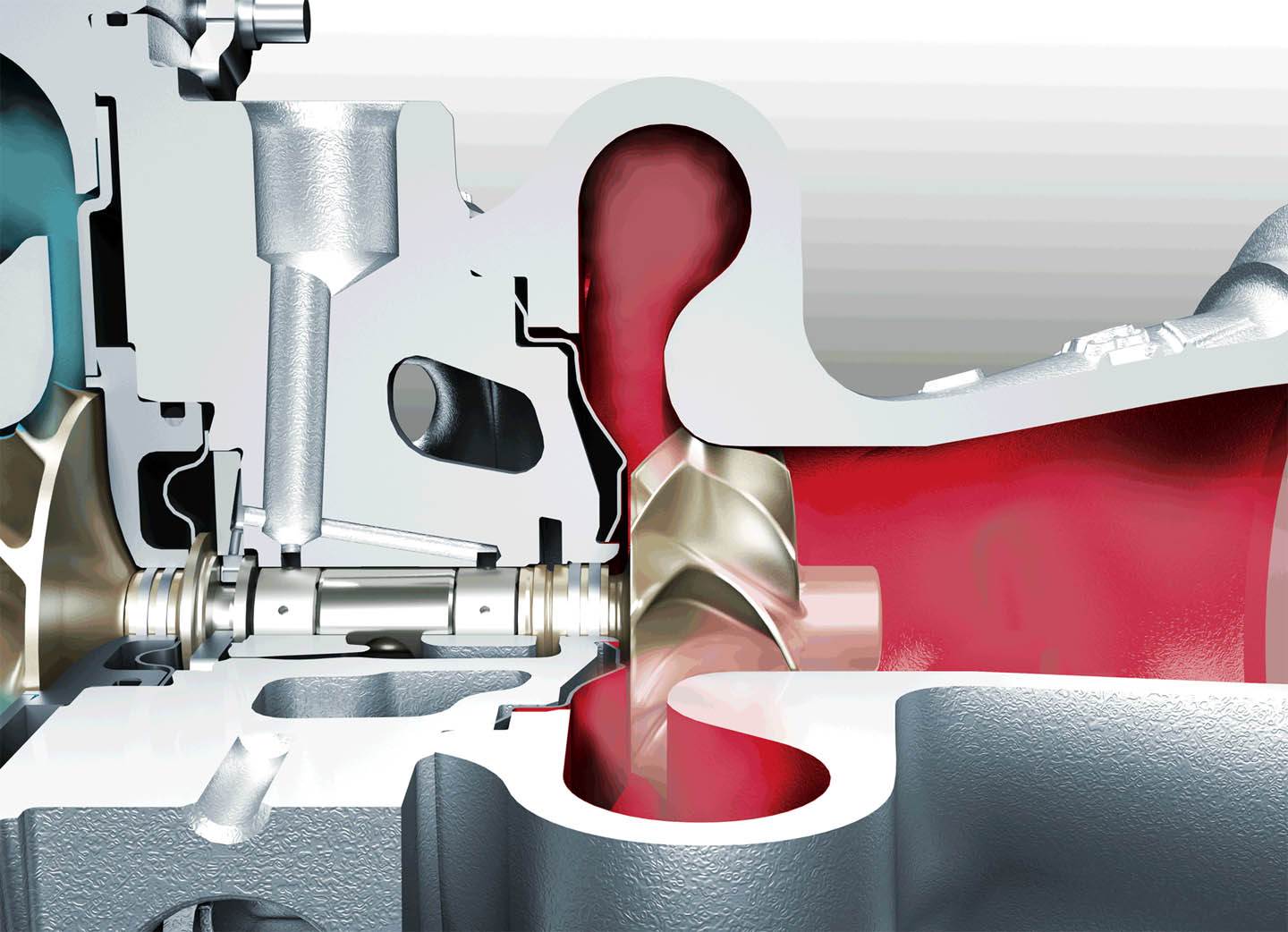

The company says its RAAX turbine technology improves engine response and also increases efficiency. While the most common type of petrol turbocharger today, the radial turbocharger, features a radial exhaust gas flow to the turbine wheel, the new Continental turbocharger features a radial-axial flow – hence the name RAAX. This makes it possible to substantially reduce the size of the turbine wheels, and to reduce the mass moment of inertia by approximately 40 percent. The turbocharger therefore develops boost pressure more quickly in response to changing engine loads, and turbo lag is minimised. This greater efficiency also leads to reduced emissions. A new solution has also been implemented for the wastegate valve (which stops boost pressure rising too steeply at high engine output) based on an electronically controlled electric actuator developed by Continental.

“We are entering the Chinese market with cutting-edge turbocharger technology identical to that which we are already using in Europe, to meet the strict European emissions standards,” says Udo Schwerdel, head of the Turbochargers product line at Engine Systems. The production processes too, he says, are identical to those used at the European plant in Trutnov, Czech Republic. “We use standardised production processes and manufacturing equipment across all our operations worldwide. All the core processes we developed for our highly automated production system in Trutnov will also be used in Jiading and San Luis Potosi. This will help to facilitate and speed communication, employee training and sharing of lessons learned between the plants, and will support us in our goal of ensuring benchmark quality at all our sites across the world.”

Continental employs a total workforce of approximately 1,600 people in Jiading, where a range of products are built, including ABS systems. “This plant has been operating successfully for many years, and its mechanical engineering expertise will give us a useful head start when it comes to producing turbochargers,” says Schwerdel. From its current production footprint of about 2,000 square meters, the turbocharger facility is set to expand further next year - with the construction of a new building. Continental’s total investment in the new manufacturing location will run to a high double-digit million euro sum.

RELATED ARTICLES

Antolin unveils sustainable tech solutions at Beijing Motor Show

In line with its China market roadmap, Antolin is showcasing its latest advances in lighting, HMI, electronics, and sust...

Visteon wins $1.4 billion in new business in Q1 2024, launches 26 new products

Digitisation of vehicle cockpit megatrend is a key growth driver for Visteon with over $400 million of displays wins; Vi...

BMW uses Catena-X ecosystem using real-world CO2 data to enhance quality

Working together with partners and suppliers, the company has modelled a complete data chain for the first time using re...

By Autocar Pro News Desk

By Autocar Pro News Desk

20 Nov 2017

20 Nov 2017

8120 Views

8120 Views